Double-fixing-bed biomass reactor system of supplying heat by heat pipe

A reactor system and double fixed bed technology, applied in indirect heat exchangers, lighting and heating equipment, energy input, etc., can solve problems such as low calorific value and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

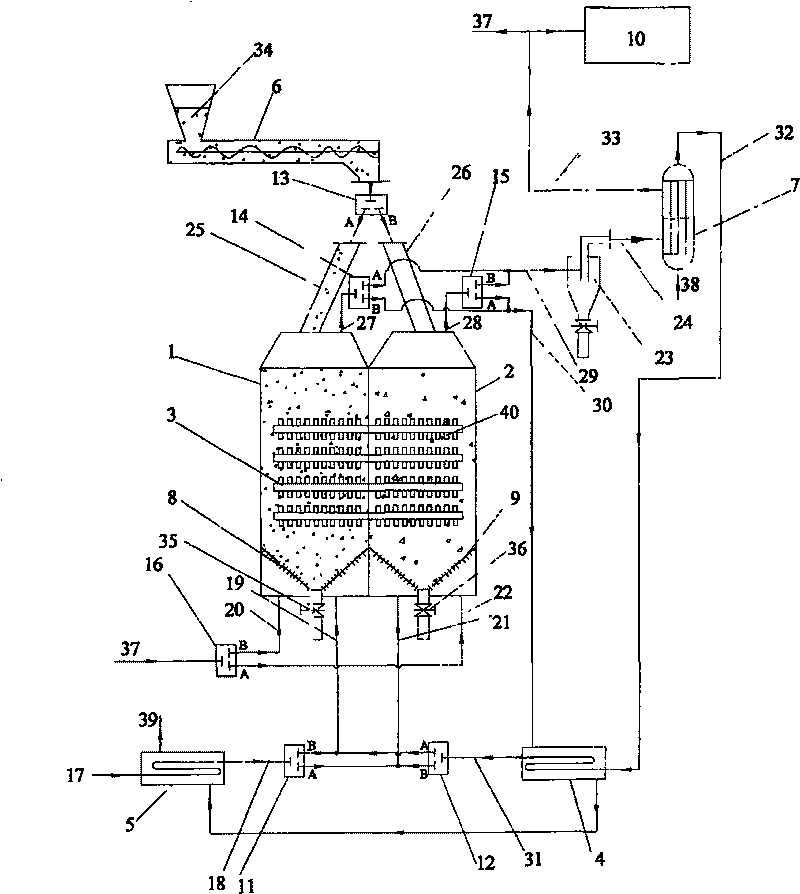

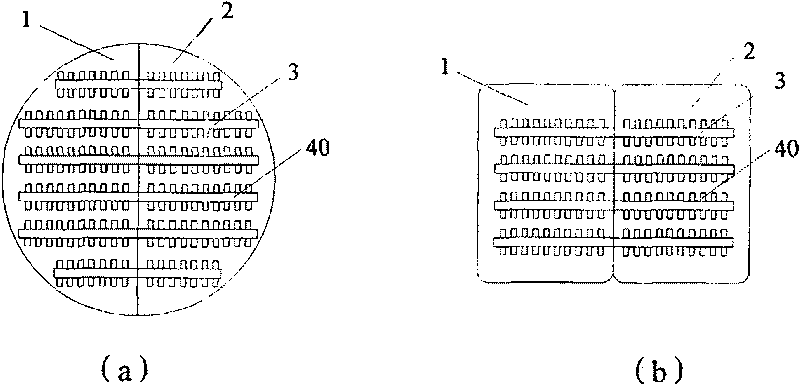

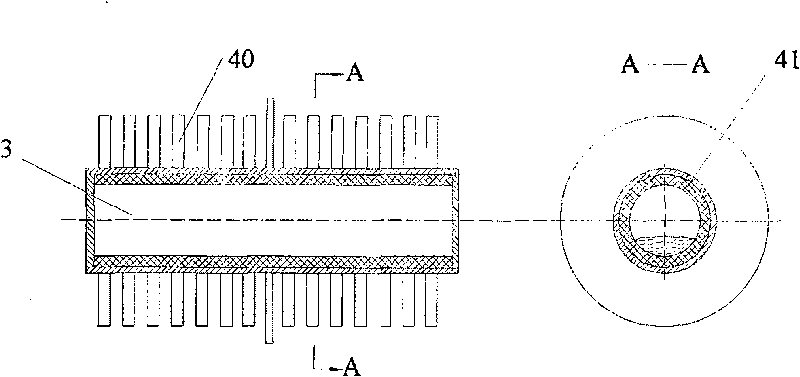

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] The present invention is a double-fixed-bed biomass reactor device and its heat utilization system utilizing heat pipes for heat supply. Separator 23, steam generator 7, steam superheater 4, air preheater 5, gas storage cabinet 10 and screw feeder 6. Reactors 1 and 2 are respectively equipped with the same feed ports 25 and 26, partial gas inlets 20 and 22, reactor 1 combustion air inlet or superheated steam inlet 19, reactor 2 combustion air inlet or superheated steam inlet 21. Reactor 1 gas outlet or flue gas outlet 27, reactor 2 gas outlet or flue gas outlet 28, ash outlets 35 and 36. Between reactors 1 and 2, there are combustion-supporting air inlet reversing valve 11, superheated steam inlet reversing valve 12, biomass inlet reversing valve 13, gas outlet or flue gas outlet reversing valve 14 and 15, part of the gas Inlet reversing valve 16. The heat pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com