Slide-rail supporting structure

A slide rail and structure technology, applied in the field of slide rail support structure, can solve problems such as insufficient support force, and achieve the effects of increased support, safer support, and more stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

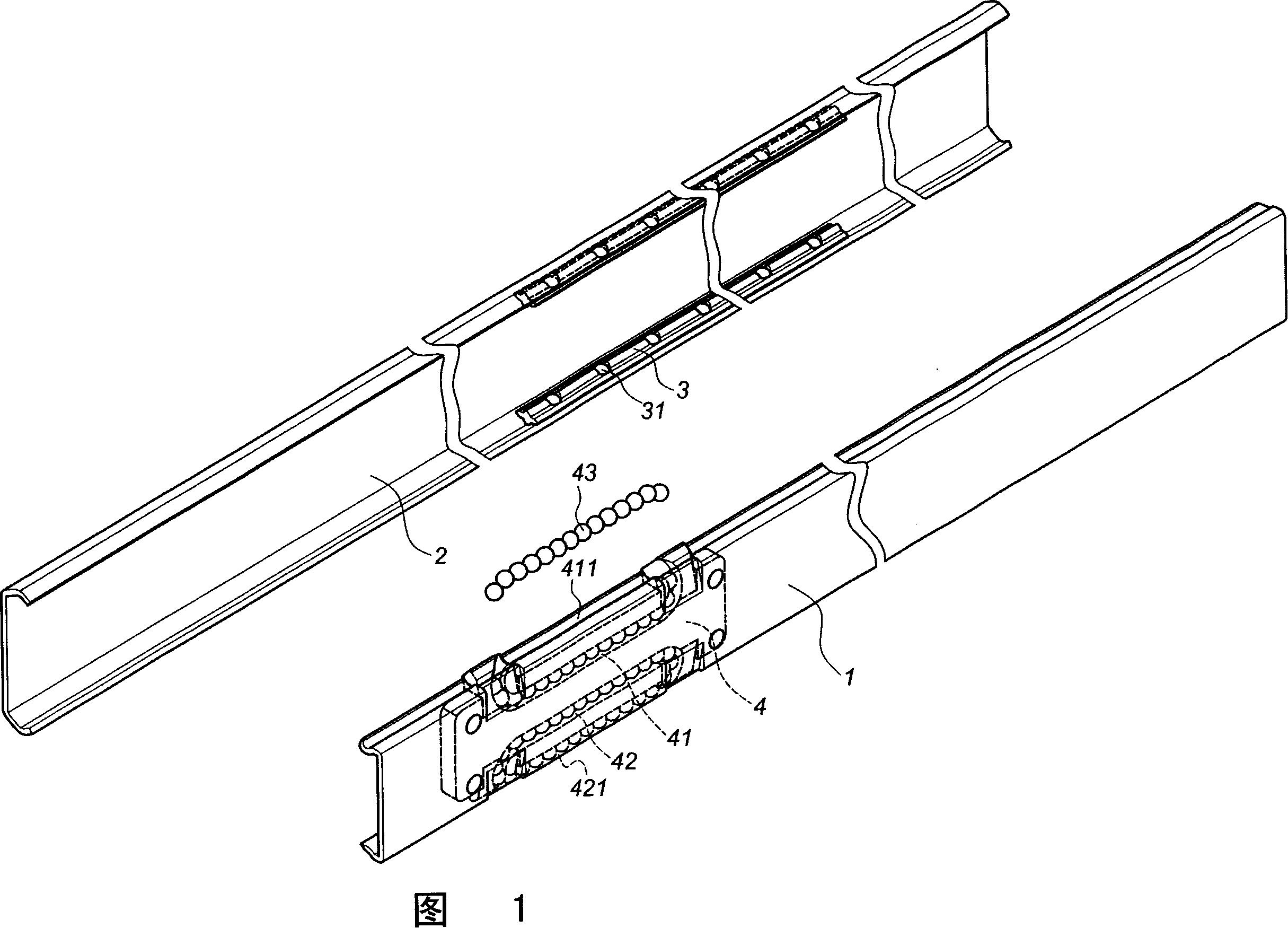

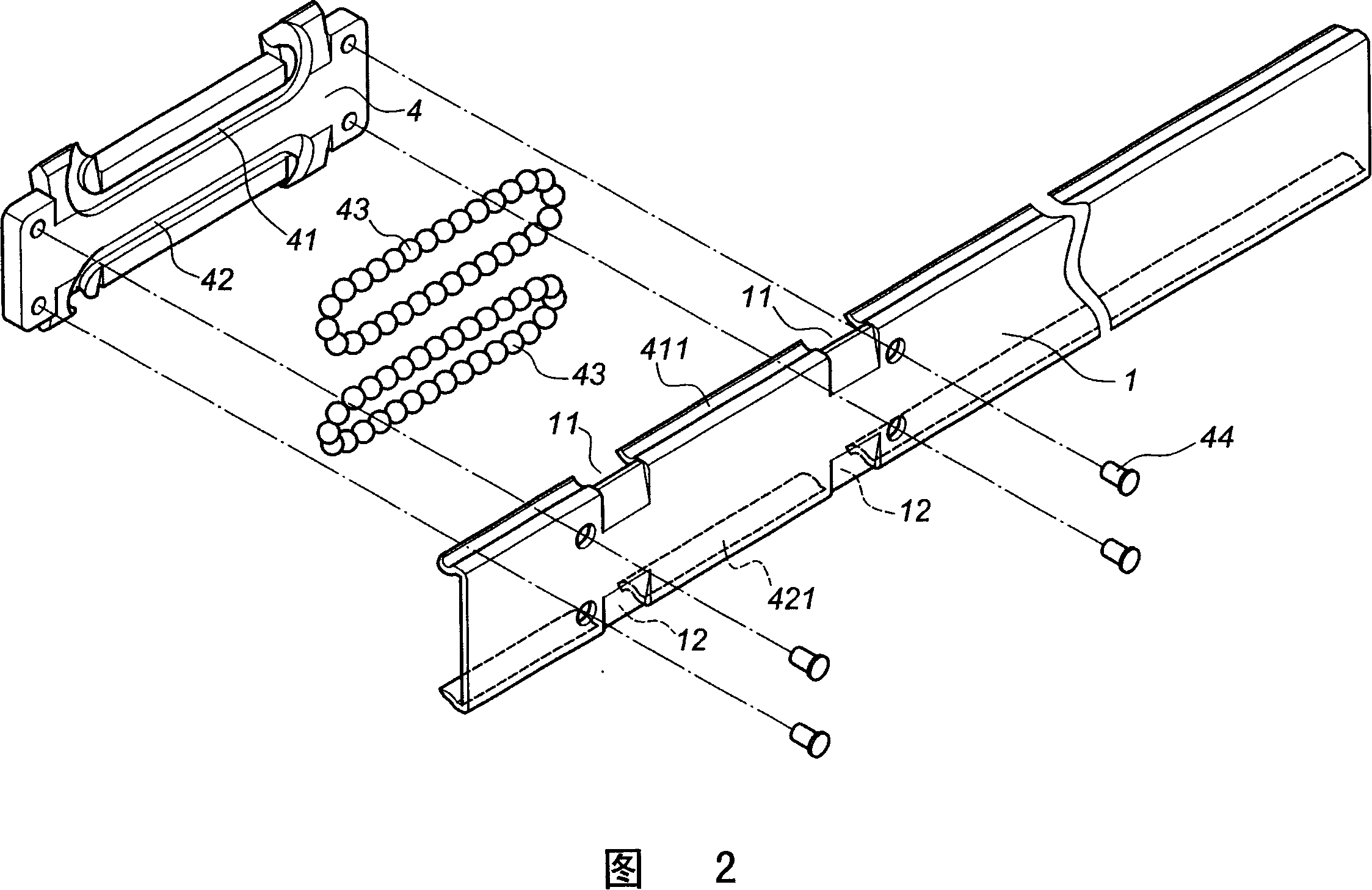

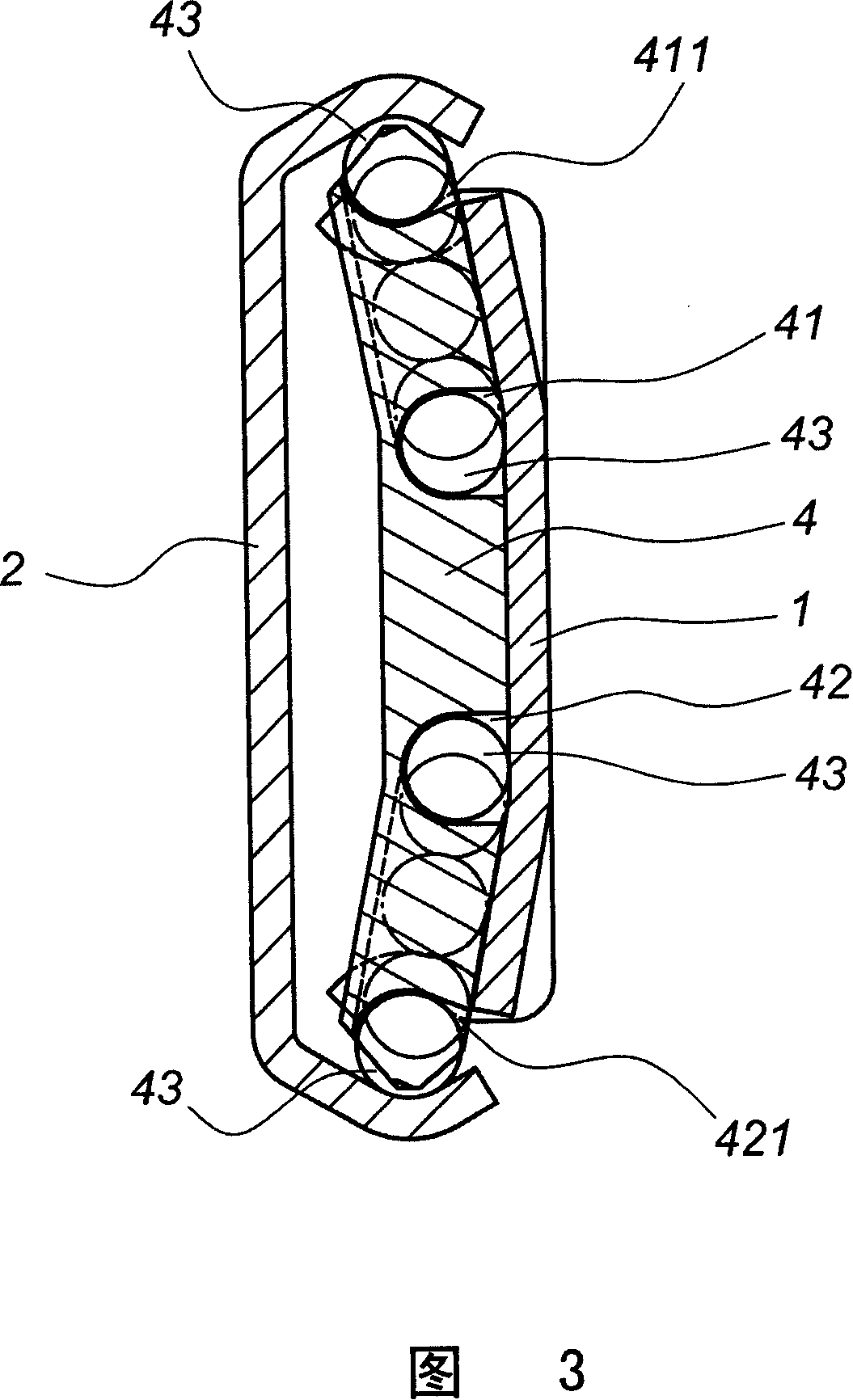

[0019] As shown in Figures 1 to 3, the structure of the first example of the present invention is a two-stage slide rail comprising an inner rail 1 and an outer rail 2, and the inner rail 1 is connected with an inner ball carrier 3 by means of an inner ball 31 Sliding in the outer rail 2, where:

[0020] The inner rail 1 is provided with a ball shaft member 4 near its end. The ball shaft member 4 is in the shape of a wide flat block and includes an upper bead groove 41, a lower bead groove 42 and a ball 43. The upper bead groove 41 and the lower bead groove 42 are circular bead grooves with a circular path, and the upper bead groove 41 and the lower bead groove 42 have an open section 411, 421 to correspond to the outer rail 2, in this example, the open section 411, 421 is the inner rail The bead groove of a section of the rail body itself at the end of 1, the two ends of the bead groove of the inner rail 1 are provided with gaps 11 and 12 corresponding to the outlets of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com