Novel compound rubber strip for hollow glass

A glass and rubber strip technology, which is applied in the field of new composite rubber strips for insulating glass, can solve the problems of poor tensile strength, high material cost, and insufficient support force of a single aluminum core frame, and achieve good tensile strength and good moisture absorption performance , The effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

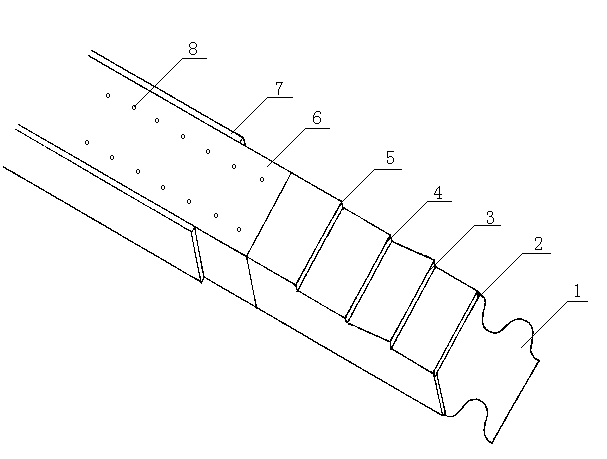

[0024] see figure 1 As shown, the novel composite glue strip for hollow glass of the present invention includes a support plate 1, a glue layer I2, a moisture barrier belt 3, a glue layer II4, a molecular sieve layer 5, an aluminum foil 6, an outer glue layer 7 and an air hole 8, Among them, the support plate 1 is bonded to the colloidal layer I2, and a water vapor barrier belt 3 is arranged between the two colloidal layers I, II2, and 4; one side of the molecular sieve layer 5 is bonded to the colloidal layer II4, and the other side is It is bonded with the aluminum foil 6; the outer rubber layer 7 is arranged on the two facades of the rubber strip to be in contact with the glass respectively.

[0025] The support plate 1 is a large curved wavy aluminum strip or a polyester sheet.

[0026] Vent holes 8 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com