Surface acoustic wave gas sensor with sensitive getter layer and process for its manufacture

一种传感器、气体的技术,应用在使用声波/超声波/次声波分析流体、使用声波/超声波/次声波进行材料分析、仪器等方向,能够解决不能测量简单分子浓度、不能测量真空度、灵敏层低灵敏度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

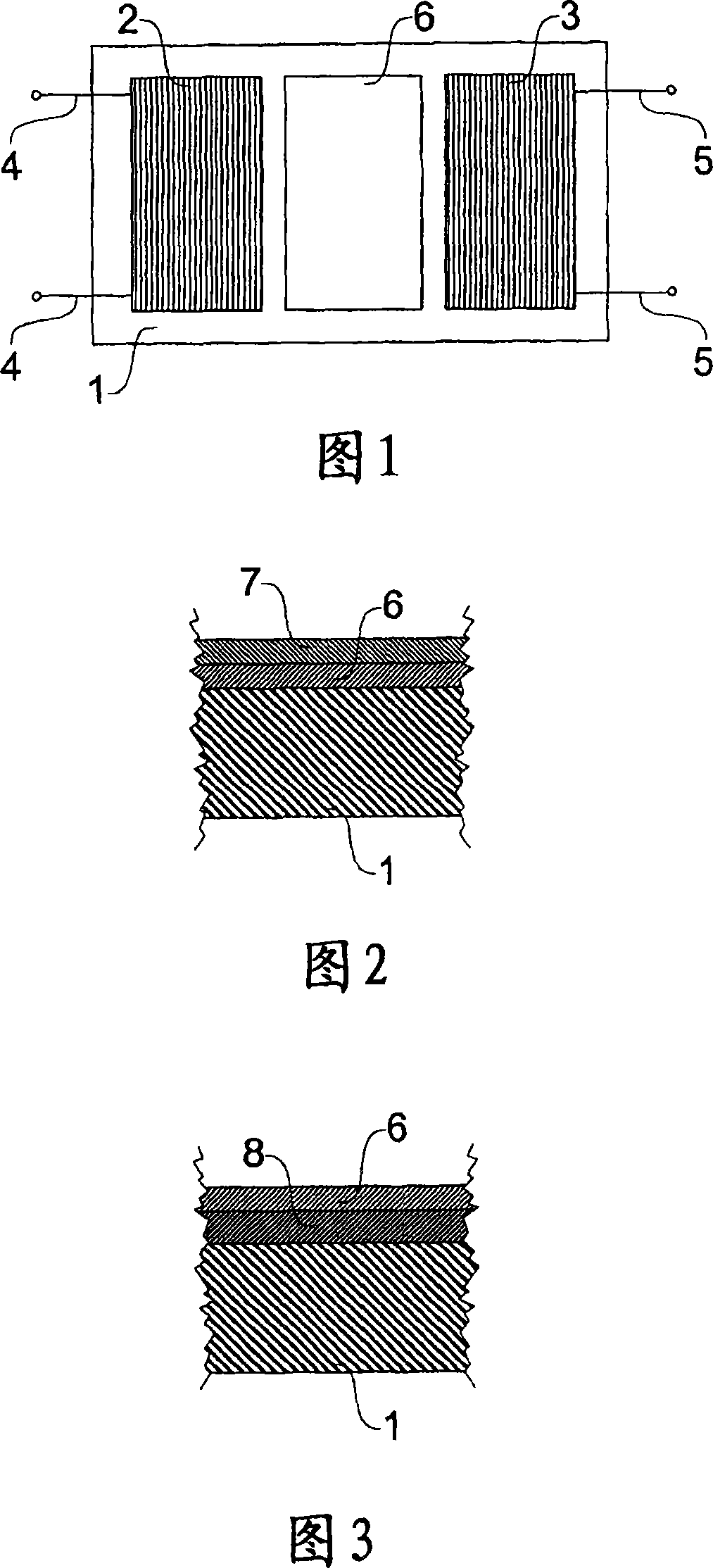

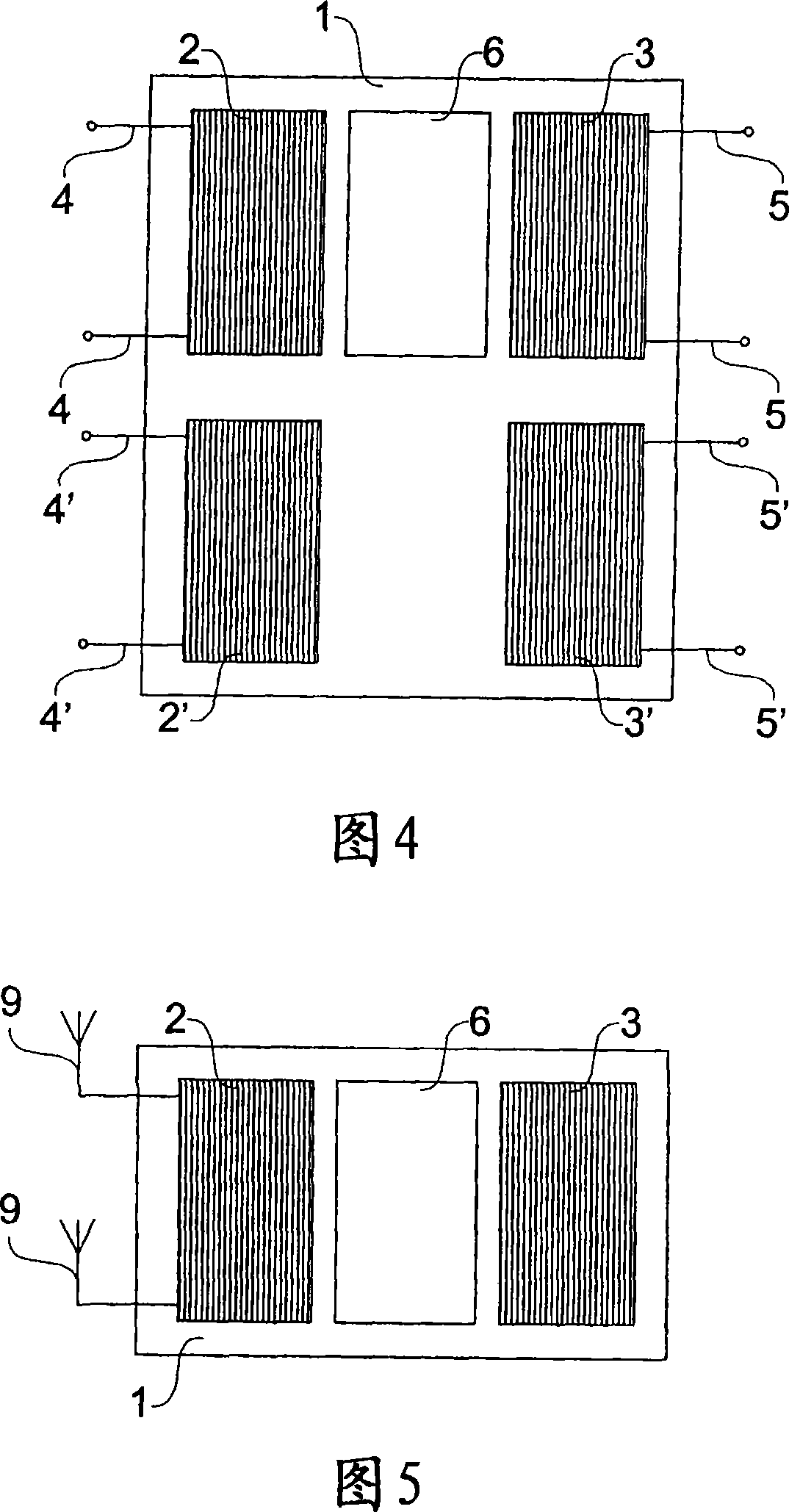

[0019] Referring to Fig. 1, it can be seen that the gas sensor according to the first embodiment of the present invention comprises: a piezoelectric substrate 1, and two interdigits of one or more input or output wires 4, 5 are arranged on the piezoelectric substrate The type transducers 2, 3 can be wired or wirelessly connected to circuits and / or electronic control devices. At least one layer 6 of gas-sensitive material is arranged on the surface of the substrate 1 between the two transducers 2 , 3 .

[0020] According to the invention, the sensitive layer 6 suitably contains a getter material, so that molecules absorbed by this getter material can change the frequency of the electrical signal transmitted between the transducers 2,3. Thus, with a suitable calibration curve, it is possible to measure the vacuum in an evacuated environment in which the sensor is arranged and the change in frequency is measured.

[0021] In particular, the sensitive layer 6 is a getter film who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com