Gas sandstone fire extinguisher

A fire-extinguishing device and gas-fired technology, applied in fire rescue and other directions, can solve the problems of high labor intensity, high risk, and limited vehicle travel, and achieve the effect of good fire-extinguishing effect and high fire-extinguishing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

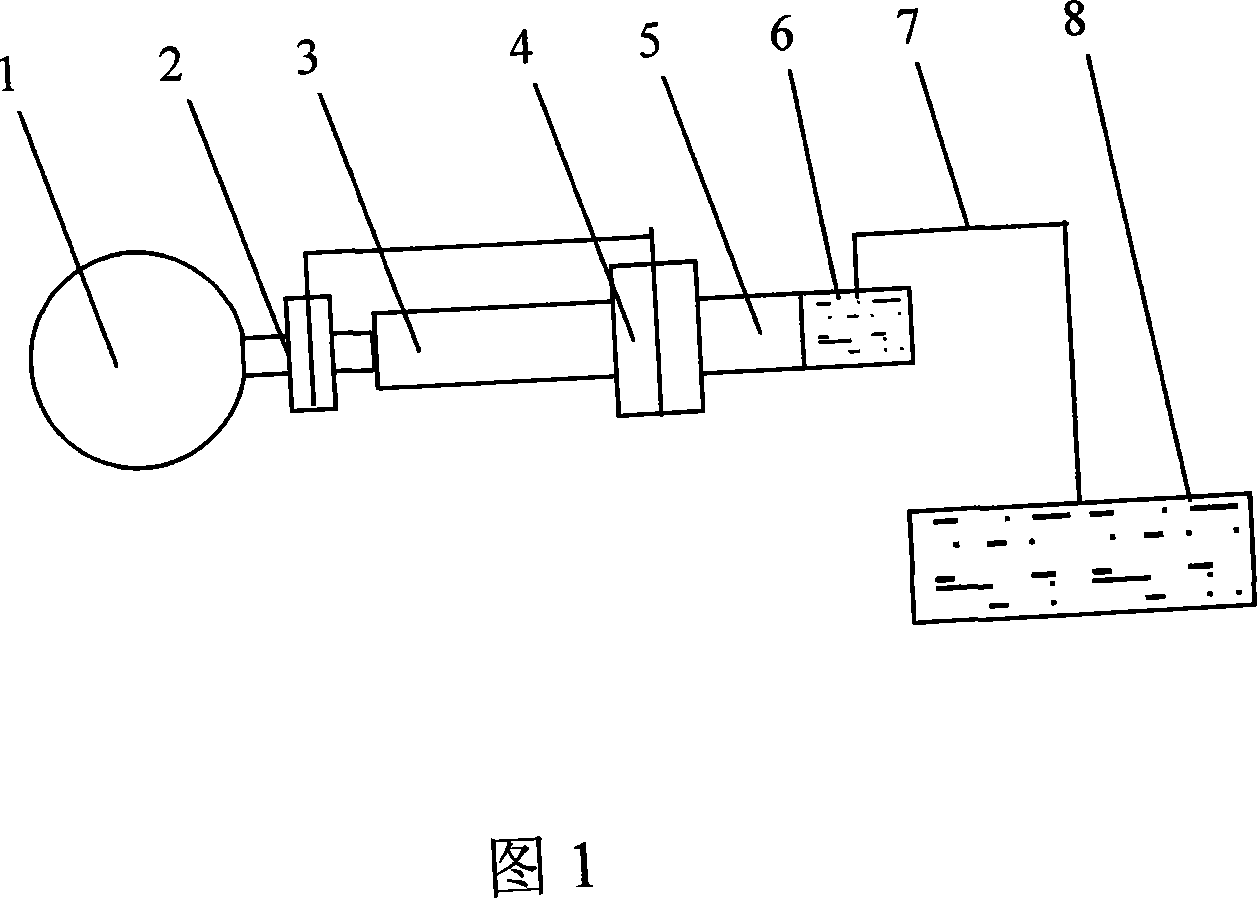

[0016] When the present invention was implemented, its main structure included a sand mining machine 1, a sand conveying mechanism 2, a vibrating filter mechanism 3, a sand uniform distribution mechanism 4, a Venturi tube 5, a gas guide pipe 6 and a jet gas turbine 7; sand and dust The fire extinguishing medium is taken from the fire extinguishing site and collected by the sand excavator 1. The collected sand, gravel and dust are separated from other impurities by the sand conveying mechanism 2, and then the sand, gravel and dust are transported to the vibrating filter mechanism 3 , the vibrating filtration process screens out the sandstone and dust that allow the particle size to be supplied to the sand uniform distribution mechanism 4 of the fire extinguisher, and the sandstone is evenly distributed radially on the outside of the Venturi tube 5 by this mechanism. The pressure gas used as the driving force of the fire extinguisher sand is generated by the gas turbine 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com