Method for increasing sponginess property of sheet with thermoplastic reinforced by multiporous fiber

A porous fiber, thermoplastic technology, applied in the field of thermoplastic polymer sheet, can solve the problem of product strength and toughness decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A method of manufacturing a porous fiber-reinforced thermoplastic sheet with increased bulk properties will be described in detail below. The method includes orienting a portion of the reinforcing fibers, at least about 5% by weight of the reinforcing fibers, in a z-axis. The x-y plane includes the width and length of the sheet, while the z-axis direction includes the thickness of the sheet. Increasing the number of reinforcing fibers in the z-axis direction results in increased bulk, or expansion of the sheet, in forming a greater thickness than known thermoplastic sheets with the same reinforcing fiber loading.

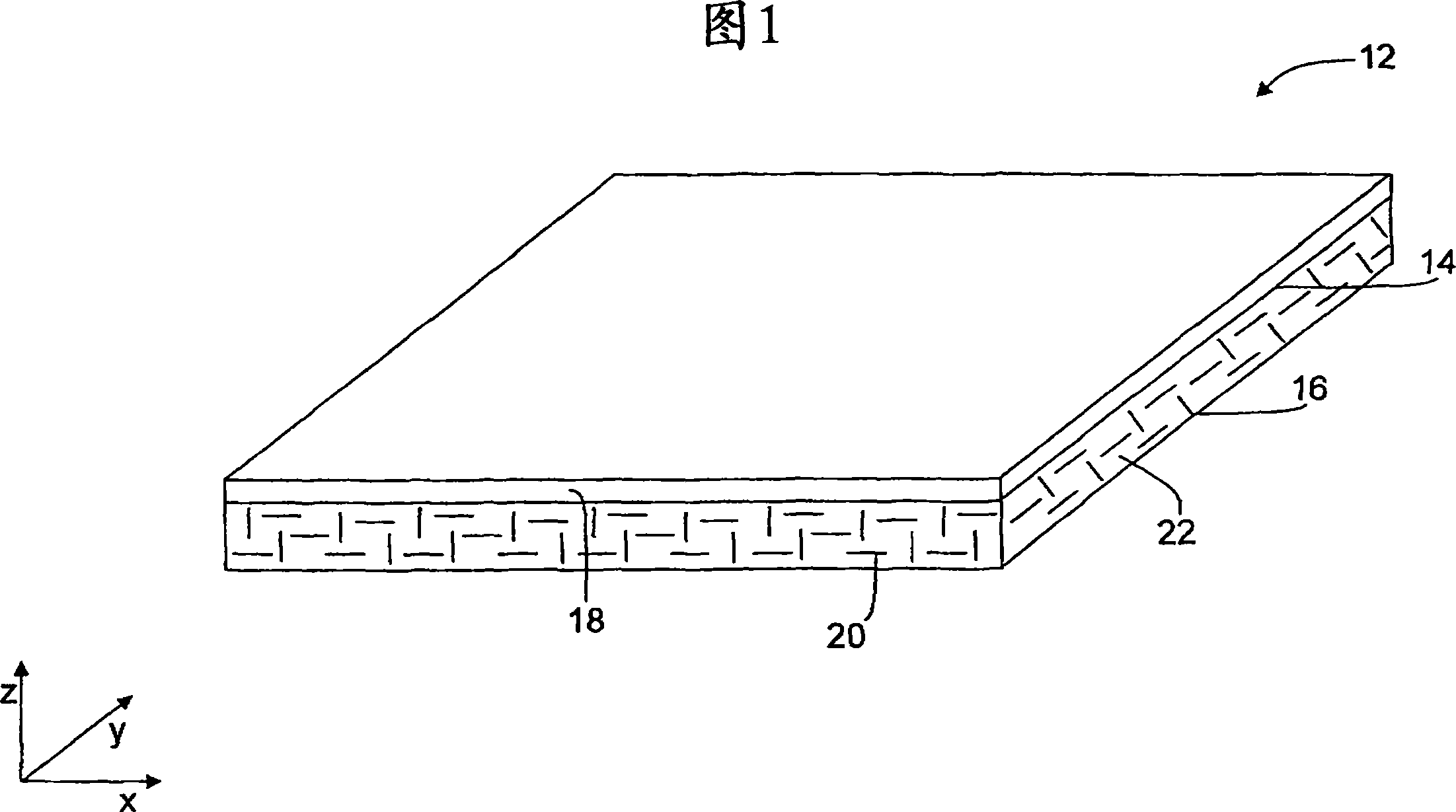

[0010] Referring to the drawings, FIG. 1 is a schematic cross-sectional view of an exemplary composite thermoplastic sheet 10 including a porous core 12 having a first surface 14 and a second surface 16 . In some alternative embodiments, the skin and / or barrier layer 18 is bonded to the first surface 14 and / or the second surface 16 .

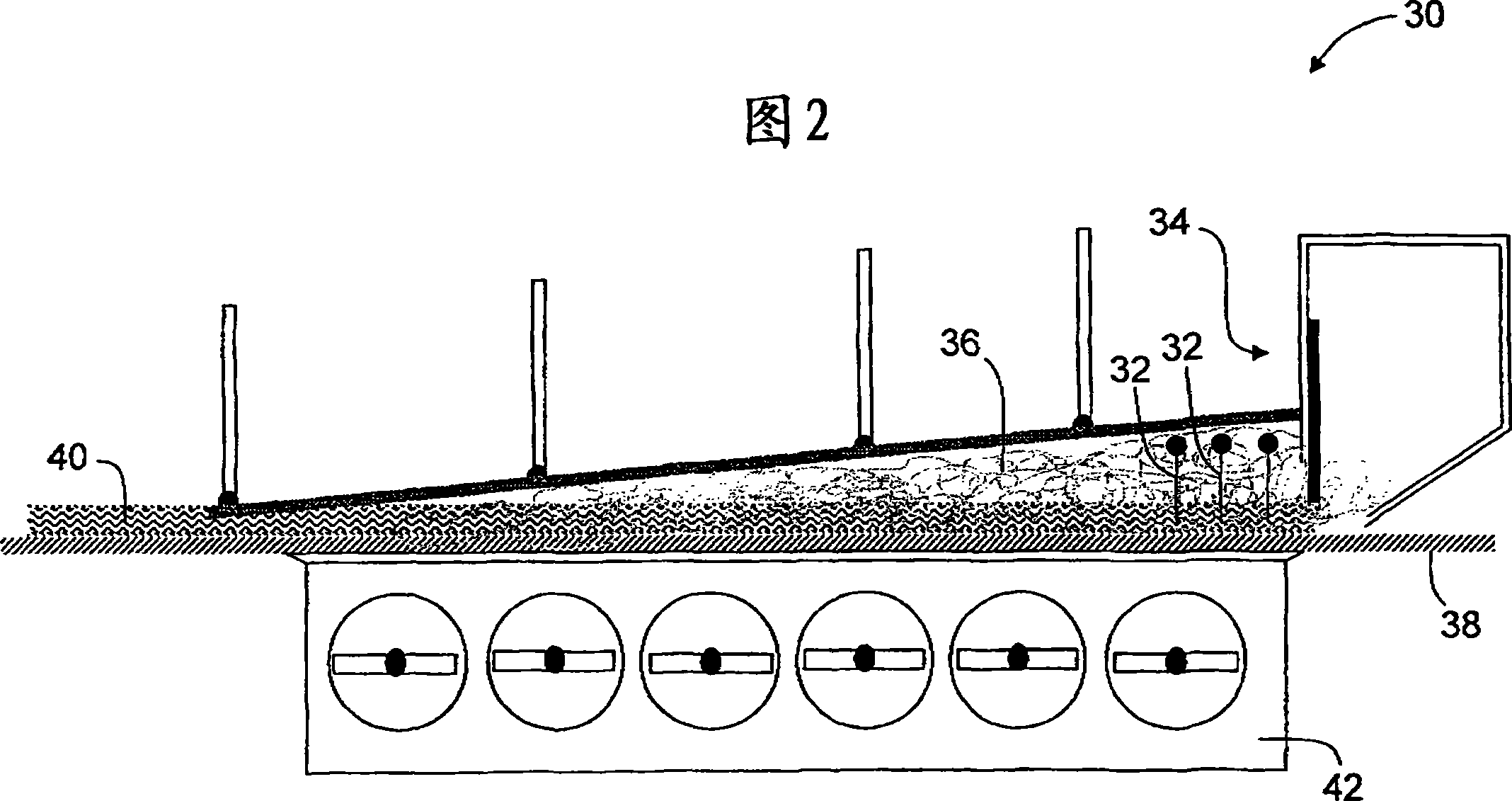

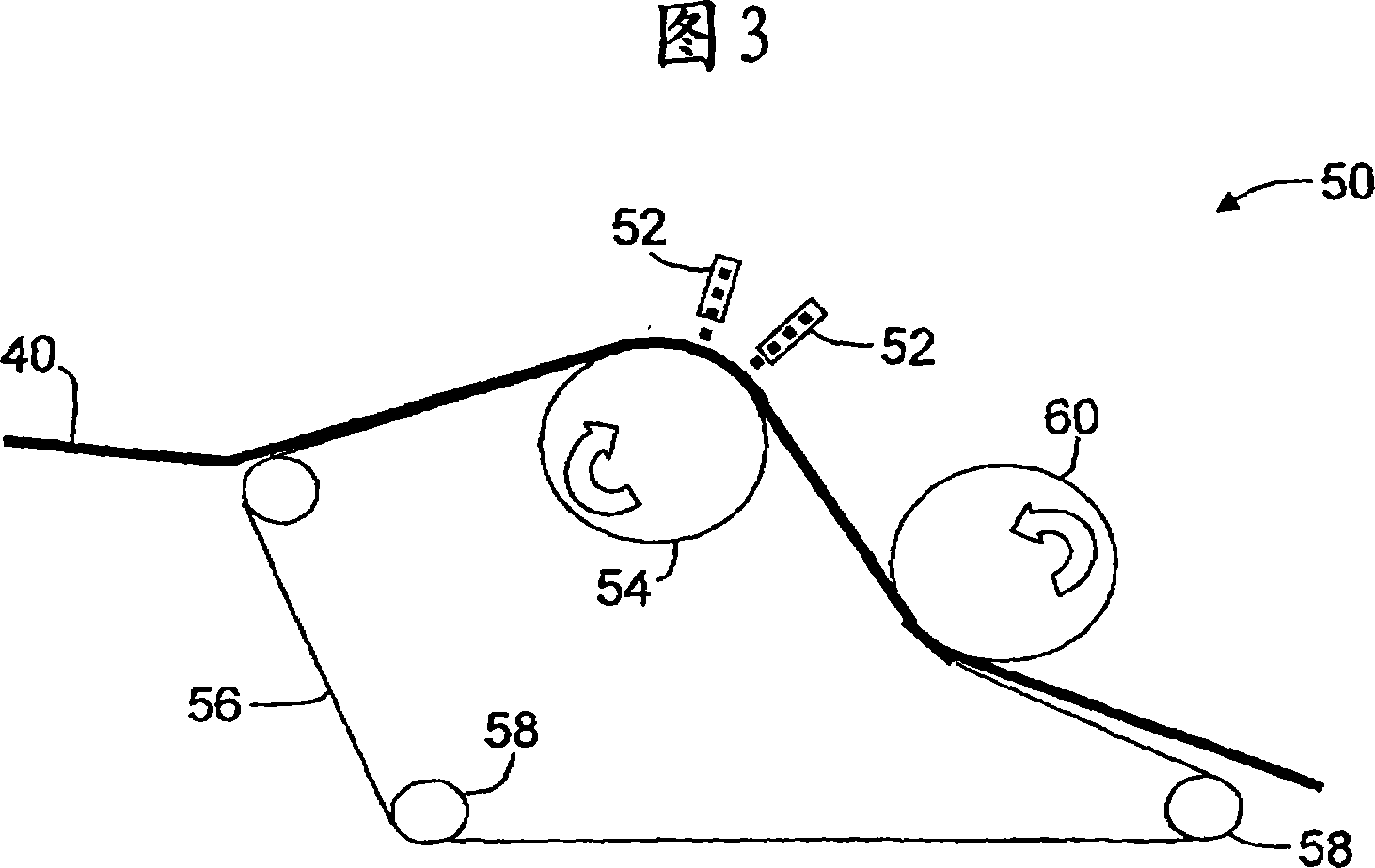

[0011] A web forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com