Device for the production of fancy yarn

A technology of colored threads and yarns, applied in the direction of textiles, papermaking, yarns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

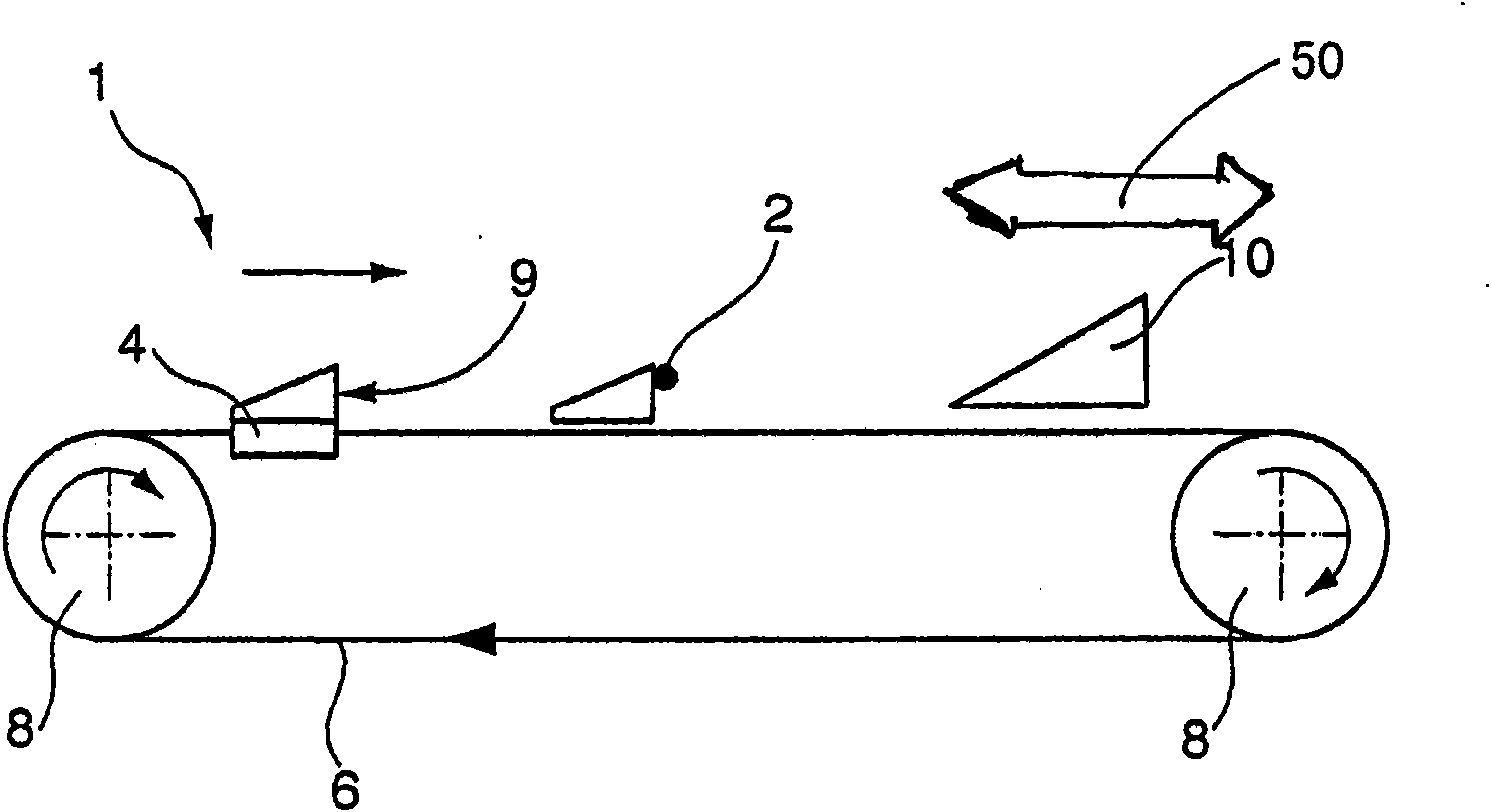

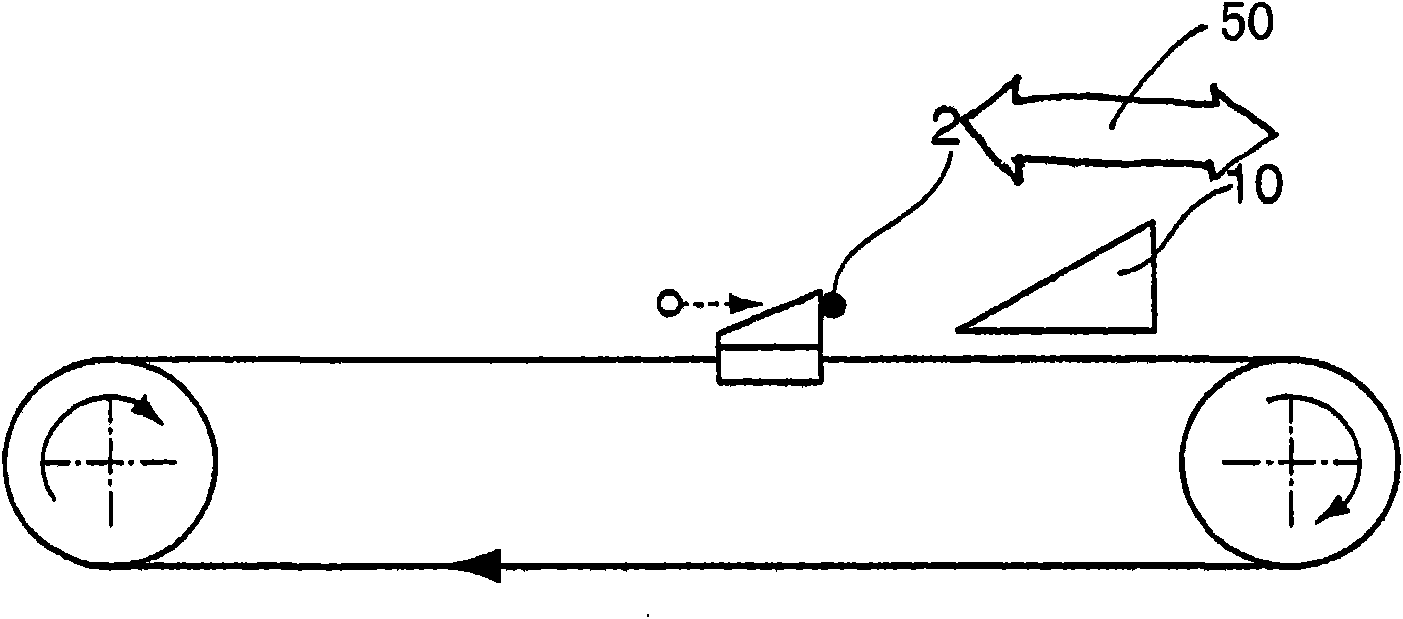

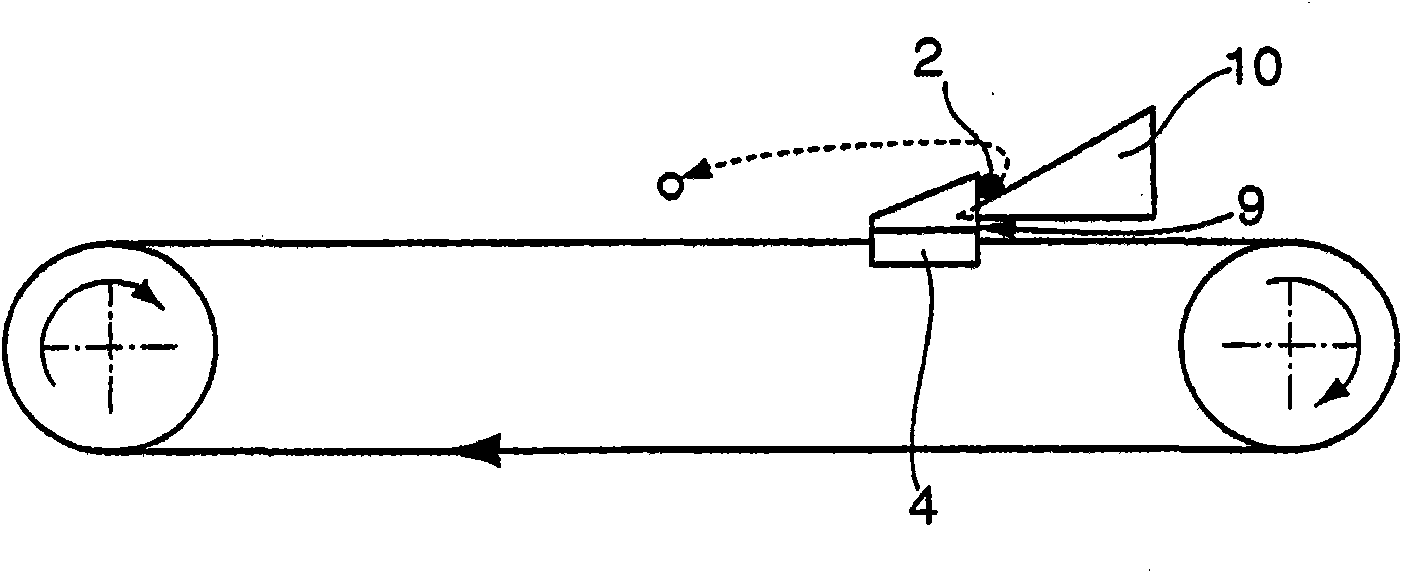

[0024] exist Figures 1a to 1c An embodiment of the slub forming device 1 according to the invention and its arrangement in a plane perpendicular to the thread path of the yarn to be texturized is schematically shown in FIG. The figures here show the lateral deflection of a filament 2 of the yarn out of its yarn path in order to form slubs during the crimping of the yarn. The slub forming device 1 has a driver 4 mounted on a cable 6 or belt of a diverting element. The cable 6 or the belt is guided around two deflectors 8 designed as wheels similarly to the case of a belt drive. At least one of the wheels is driven by an electric motor (not shown in FIG. 1 ), so that the reciprocating element with the driver 4 runs in a driven cycle (circumvention) in the direction indicated by the arrow.

[0025] The driver 4 has a thread guide 9 by which the thread 2 can be moved linearly away from the thread path by gripping the thread 2 when the driver 4 circulates, that is to say the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com