Method and equipment for sorting magnetic fine particle stage material

A fine-grained sorting technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high drying cost, drop of sorting magnetic field, and drop of sorting effect, and achieve high sorting efficiency , The effect of good selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

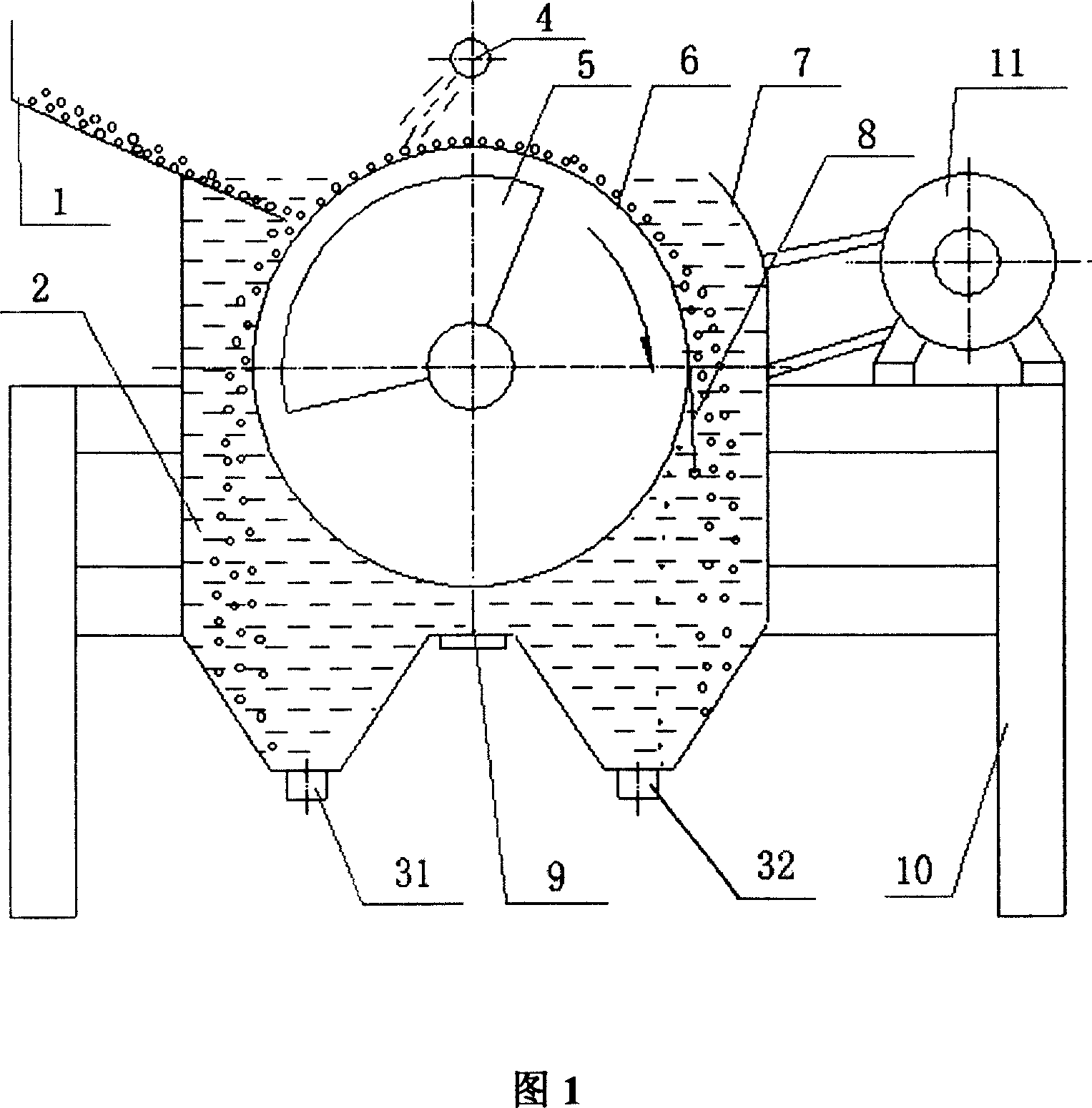

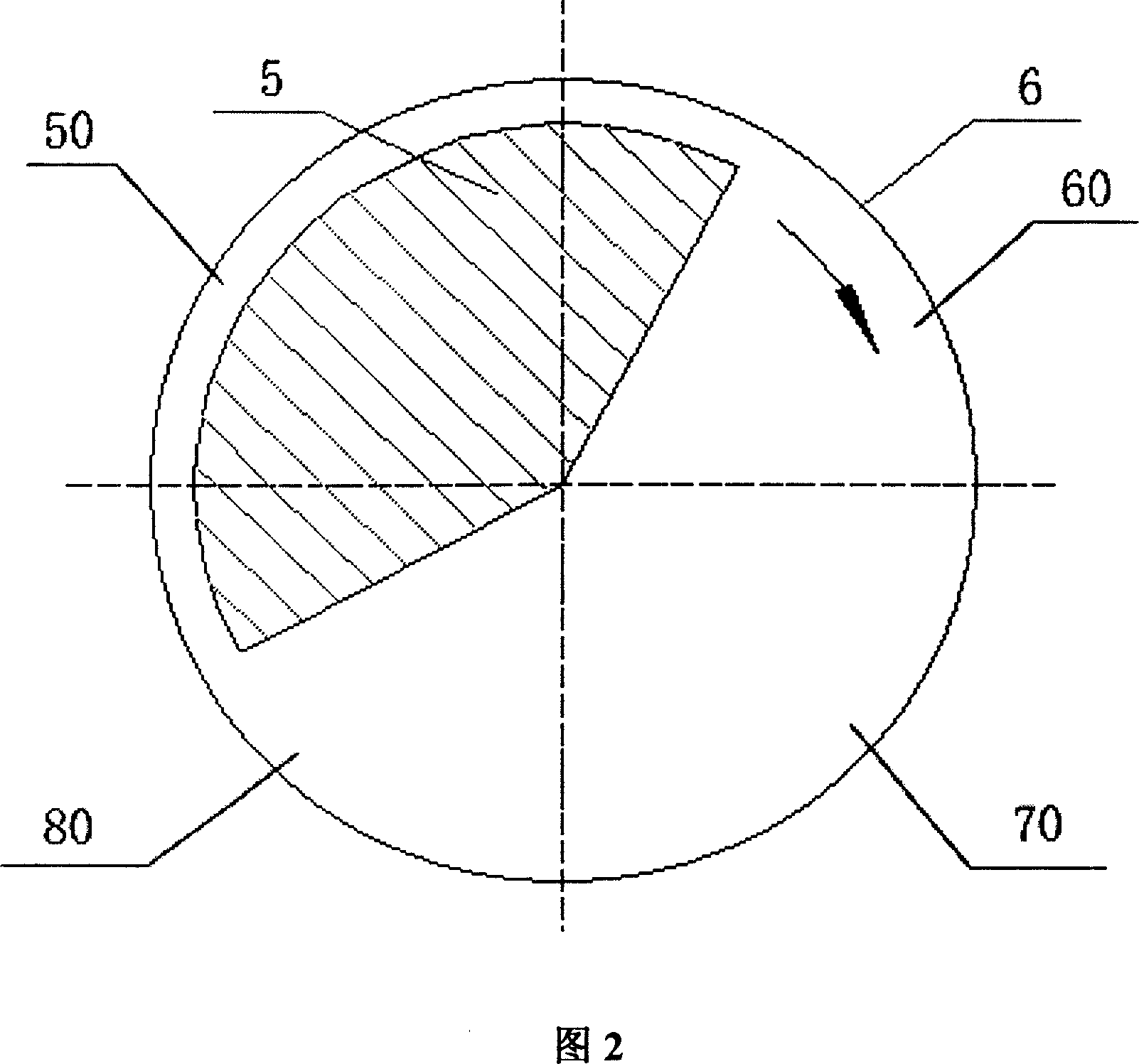

[0014] Adjust the position of the permanent magnet as shown in Figure 1; adjust the position of the regulating plate on the overflow of the sorting tank to ensure a high level of sorting liquid; make the sorting cylinder reversely rotate relative to the material; the material and the horizontal angle are 0~45 The degree direction is given to the surface of the sorting cylinder immersed in water; with the rotation of the sorting cylinder, non-magnetic minerals are not affected by the magnetic field, naturally settle in the water, and enter the tailings hopper, as tailings, from the tailings The ore nozzle is discharged; the magnetic minerals are affected by the magnetic field force of the magnet in the cylinder, adsorbed on the surface of the separation cylinder, and rotate with the separation cylinder, and at the same time, the rinsing water on the upper part of the separation cylinder has a magnetic effect on the surface of the separation cylinder. Minerals are continuously wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com