Multi-stage sorting device for recycling aluminum-plastic garbage

A recycling and garbage technology, applied in recycling technology, packaging, transportation packaging, etc., can solve the problems of easy overflow of materials, impurities mixed into open packaging bags, mesh blockage, etc., and achieve the effect of efficient sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated by the following examples.

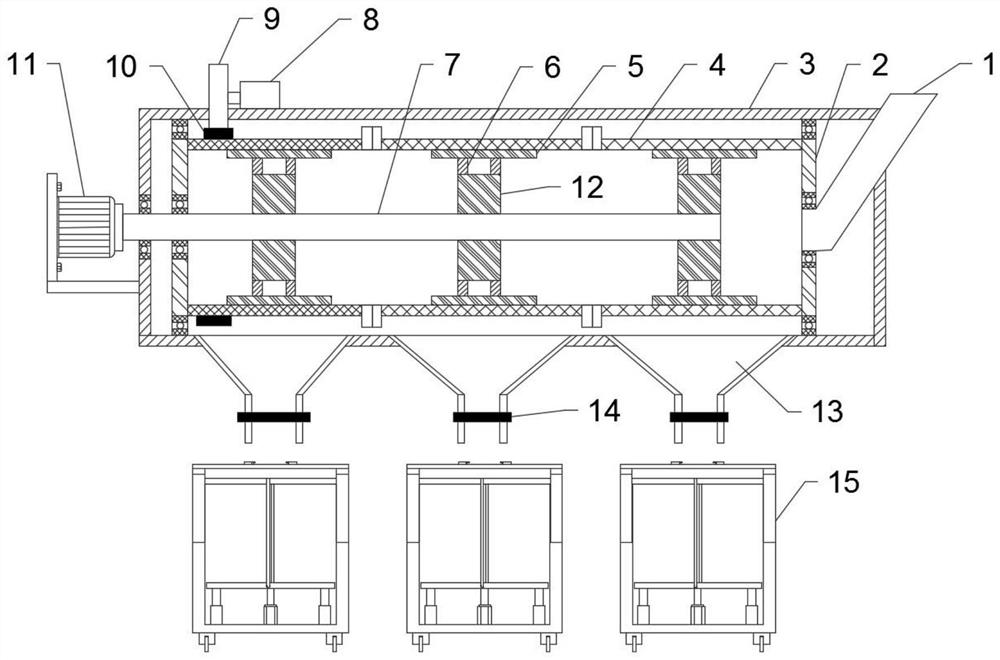

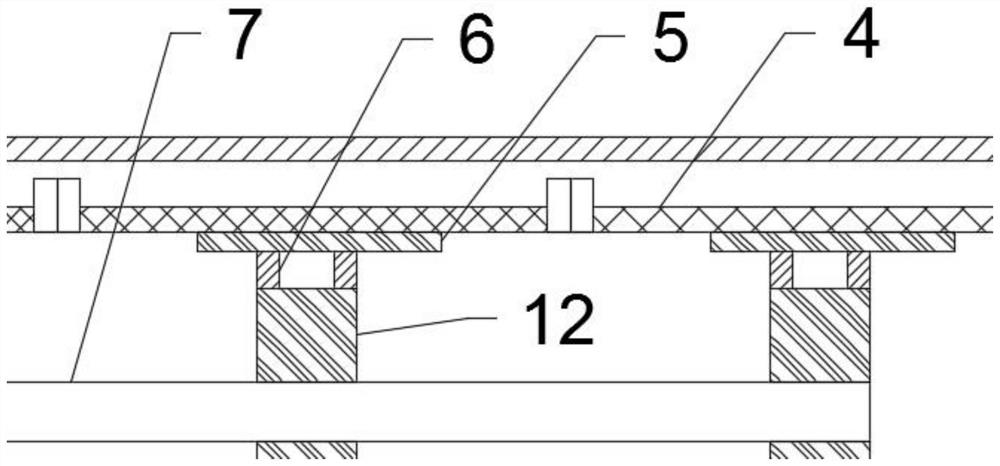

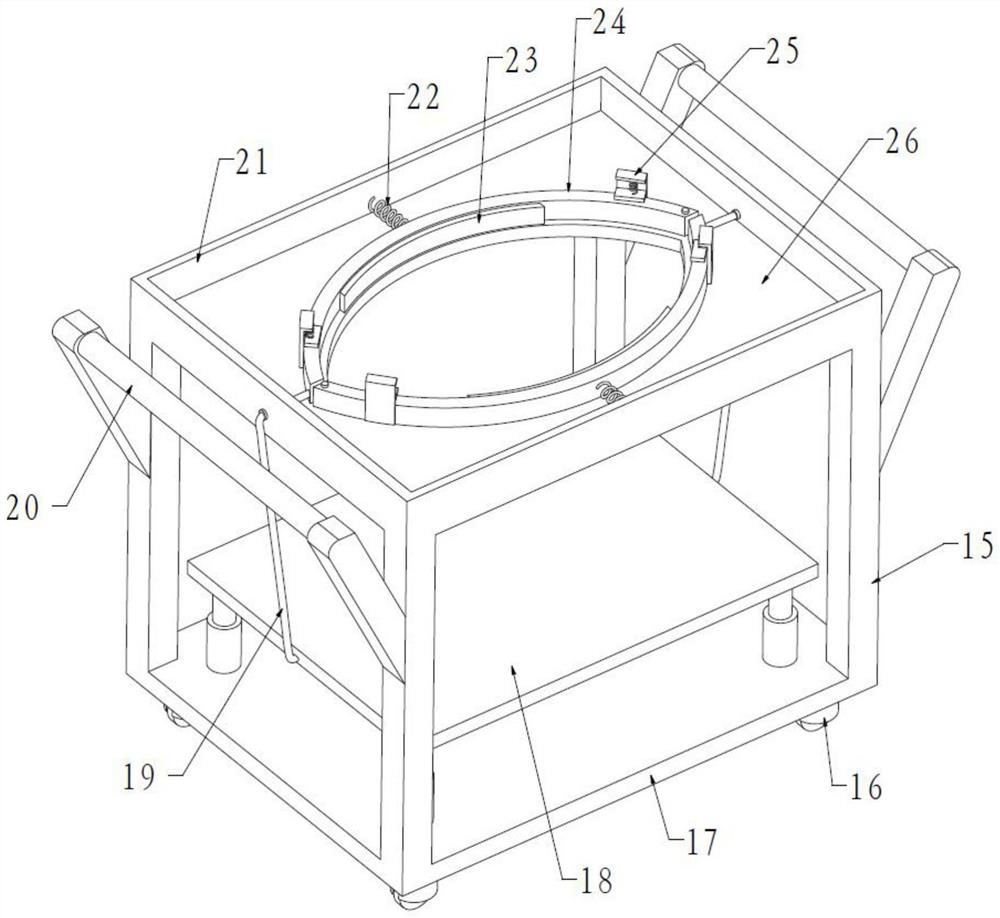

[0027] A multi-stage sorting device for resource utilization of aluminum and plastic waste, comprising a sorting cylinder 3 supported by a bracket and a transfer trolley 15, one end of the sorting cylinder 3 is provided with a feed port 1, and the inside of the sorting cylinder 3 is A drum 4 is provided, and the pipe at the bottom of the feeding port 1 is connected to the end cap 2 of the drum 4; a main shaft 7 is arranged inside the drum 4, and a stirring assembly is arranged on the main shaft 7; the bottom of the sorting drum 3 is arranged A discharge funnel 13 is provided; the transfer trolley 15 is located below the discharge funnel 13, the transfer trolley 15 includes a trolley floor 17, the bottom of the trolley floor 17 is provided with universal wheels 16, and the trolley floor 17 is provided with a lifting plate 18, and the trolley floor 17 is provided with a trolley roof plate 26 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com