Flame stabilizing burner

A flame stabilization and burner technology, which is applied in the directions of burners, gas fuel burners, combustion types, etc., can solve the problems of lack of burn stabilizers, complex swirler structures, and inability to apply flames, and achieve effective diversion. Good effect, burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

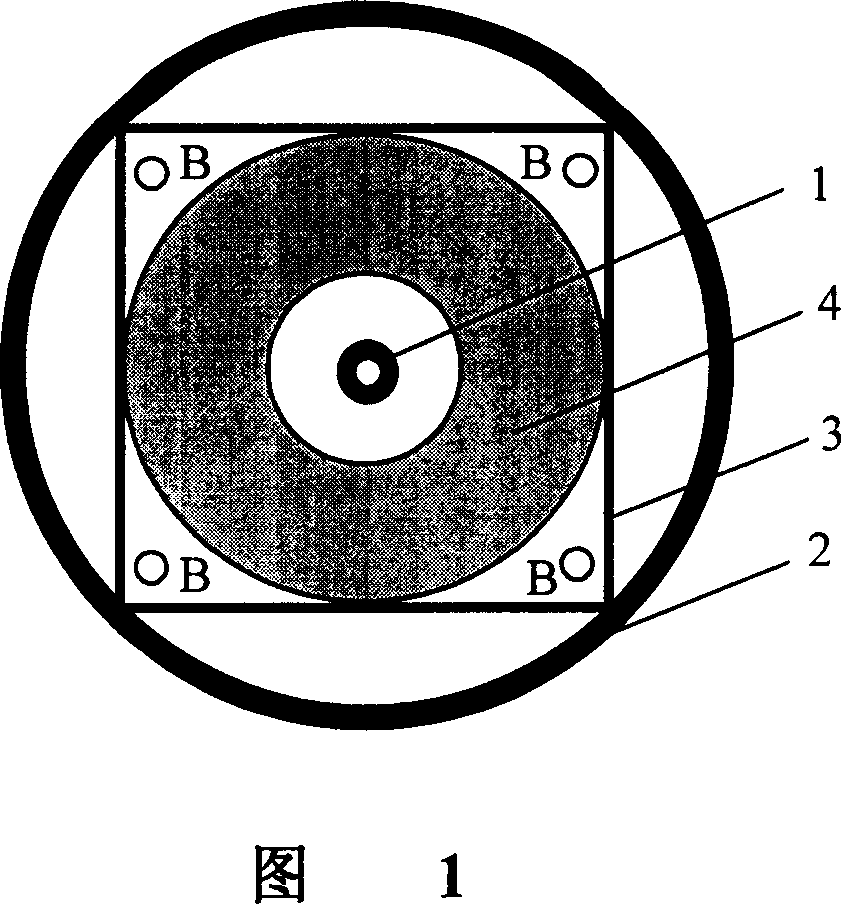

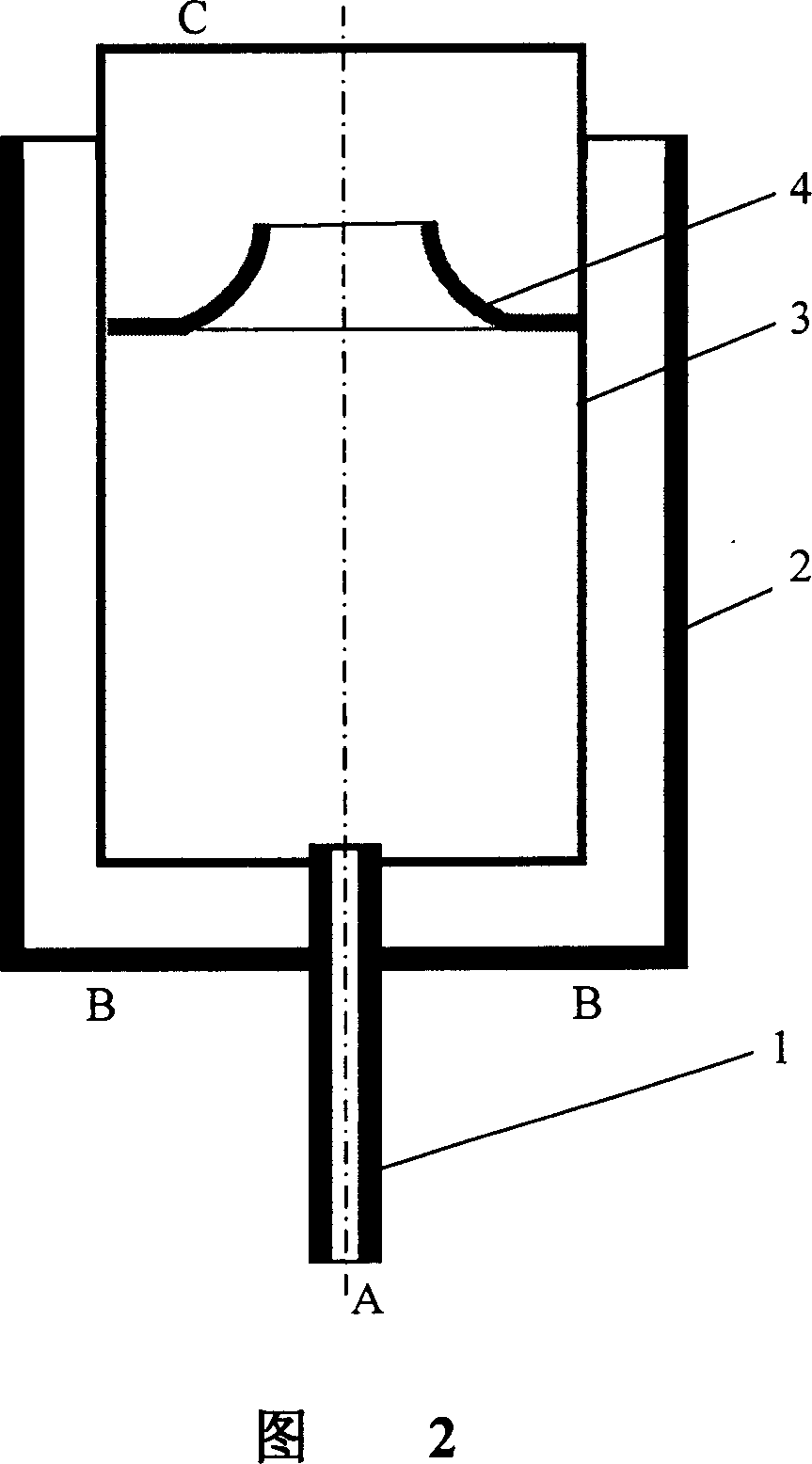

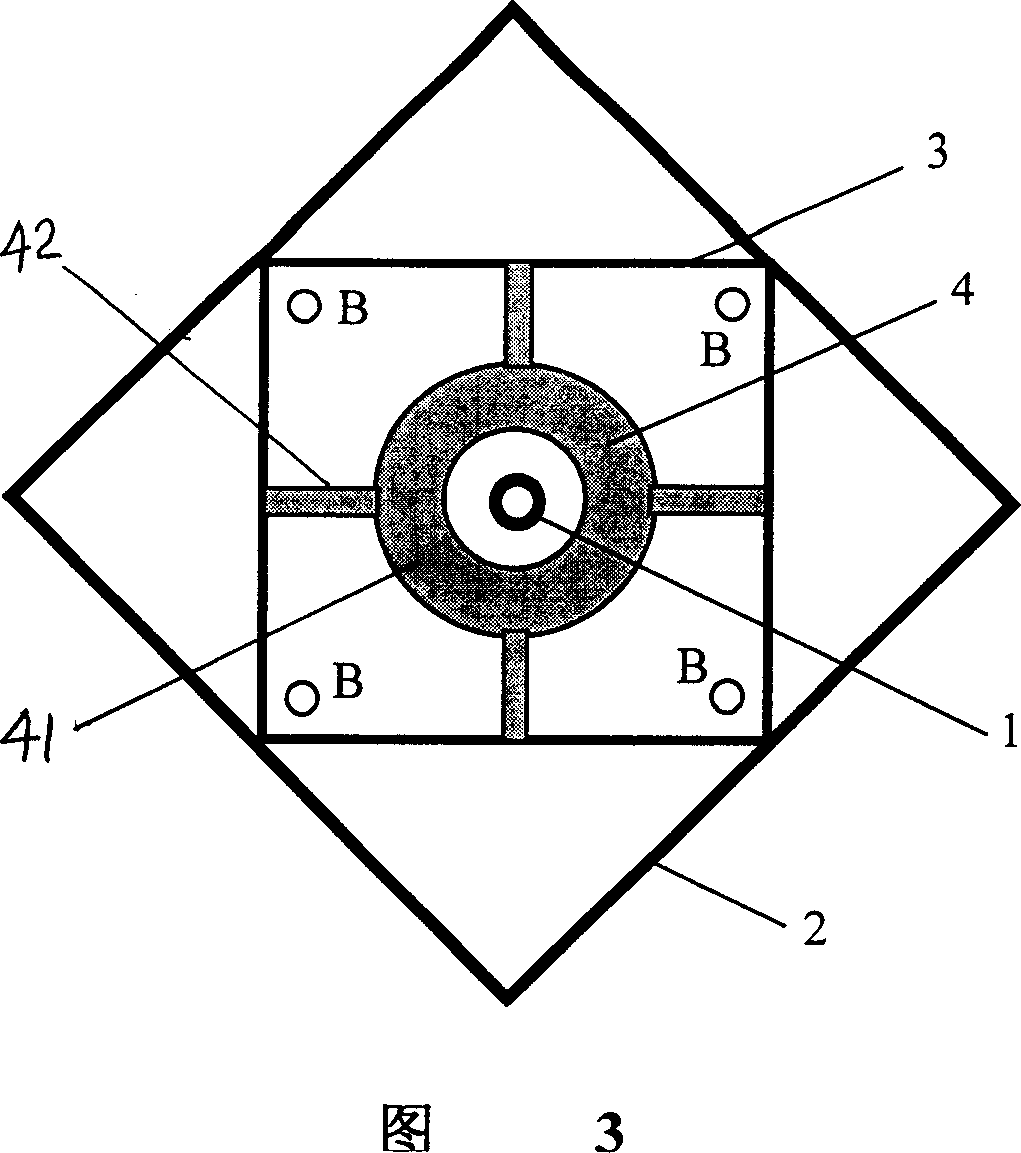

[0016] As shown in Fig. 1 and Fig. 2, the present invention includes a fuel nozzle 1, a circular cup body 2, a square cylinder body 3 and a conical annular body 4, and the cylinder body 3 is arranged in the cup body 2 , The annular body 4 is set in the cylinder body 3, and the four axes 1, 2, 3, and 4 are coincident. The top of the cylinder 3 is higher than the top edge of the cup 2, and the bottom has a certain distance from the bottom of the cup 2; the annular body 4 is connected in the cylinder 3 through a positioning block or welding on the inner wall of the cylinder 3; the bottom of the cup 2 There are four air inlets B, and the four air inlets B are located in four approximately triangular areas surrounded by the projection of the cylindrical body 3 and the annular body 4 on the bottom of the cup body 2 . Located at the center A of the cup body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com