Apparatus and method for measuring widthwise ejection uniformity of slit nozzle

一种狭缝喷嘴、测量装置的技术,应用在对表面涂布液体的装置、光学、仪器等方向,能够解决无法直接测量光刻胶厚度、无法直接测量光刻胶喷射均匀度、繁琐等问题

Inactive Publication Date: 2010-12-01

K C TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since this method directly coats the photoresist PR on the substrate, it will cause waste of expensive substrates and photoresist PR.

In particular, as the size of the substrate increases, the amount of photoresist PR consumed will further increase

Moreover, when measuring the thickness of the photoresist PR applied on the substrate, it is difficult to measure the thickness of the photoresist PR in the state where the photoresist PR applied on the substrate is not yet dry.

Therefore, the thickness of the coated photoresist PR needs to be measured after the drying process, which makes the work of measuring the thickness of the coated photoresist PR very cumbersome

In particular, since the thickness of the applied photoresist PR is measured after it goes through the drying process, it is not possible to directly measure the thickness of the actually applied photoresist PR, so that the ejection uniformity of the photoresist cannot be directly measured

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

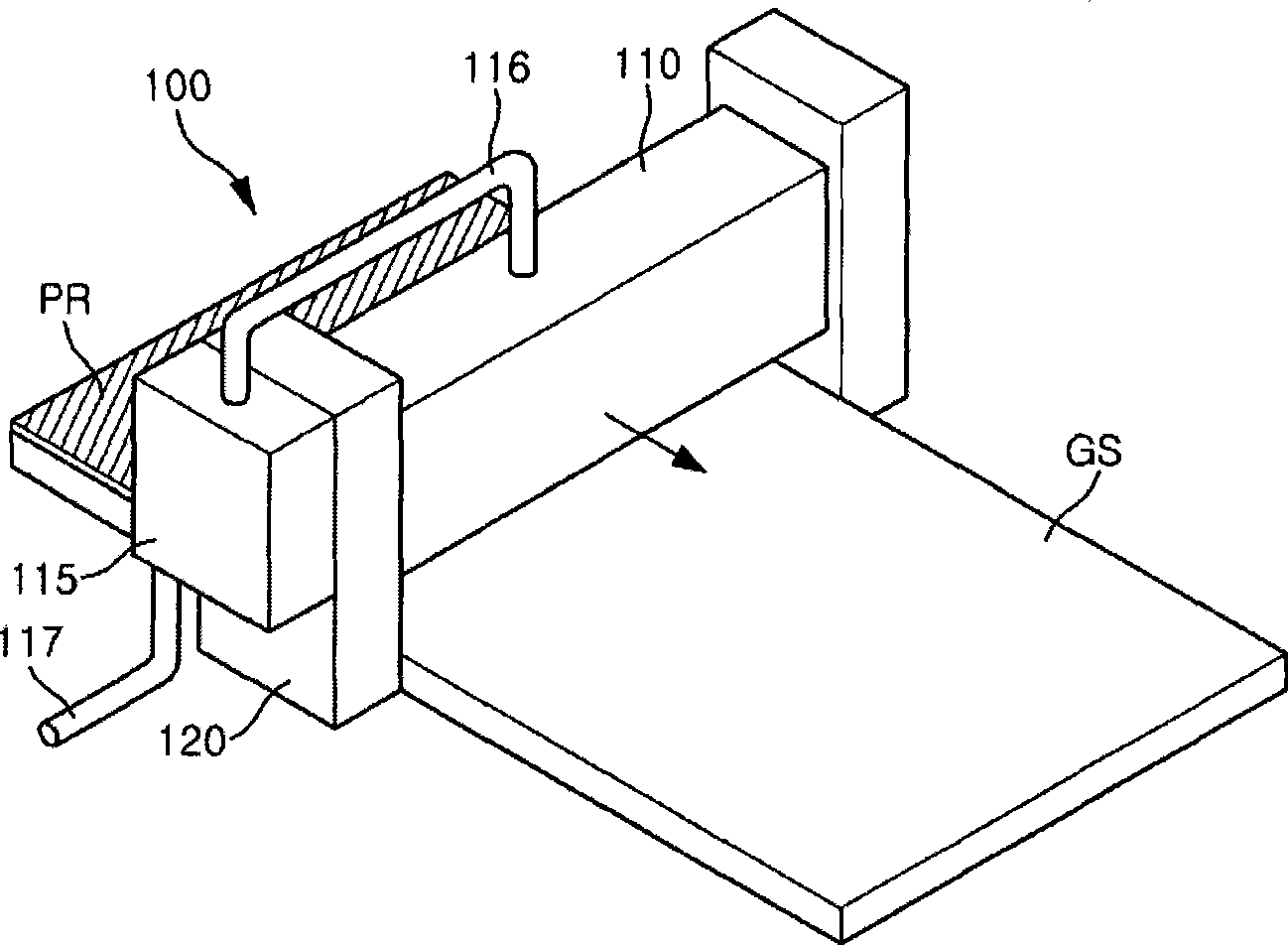

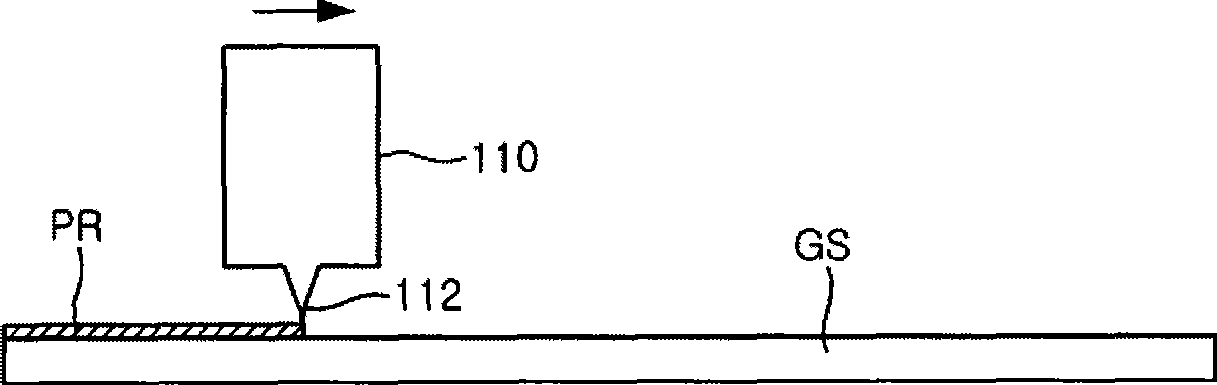

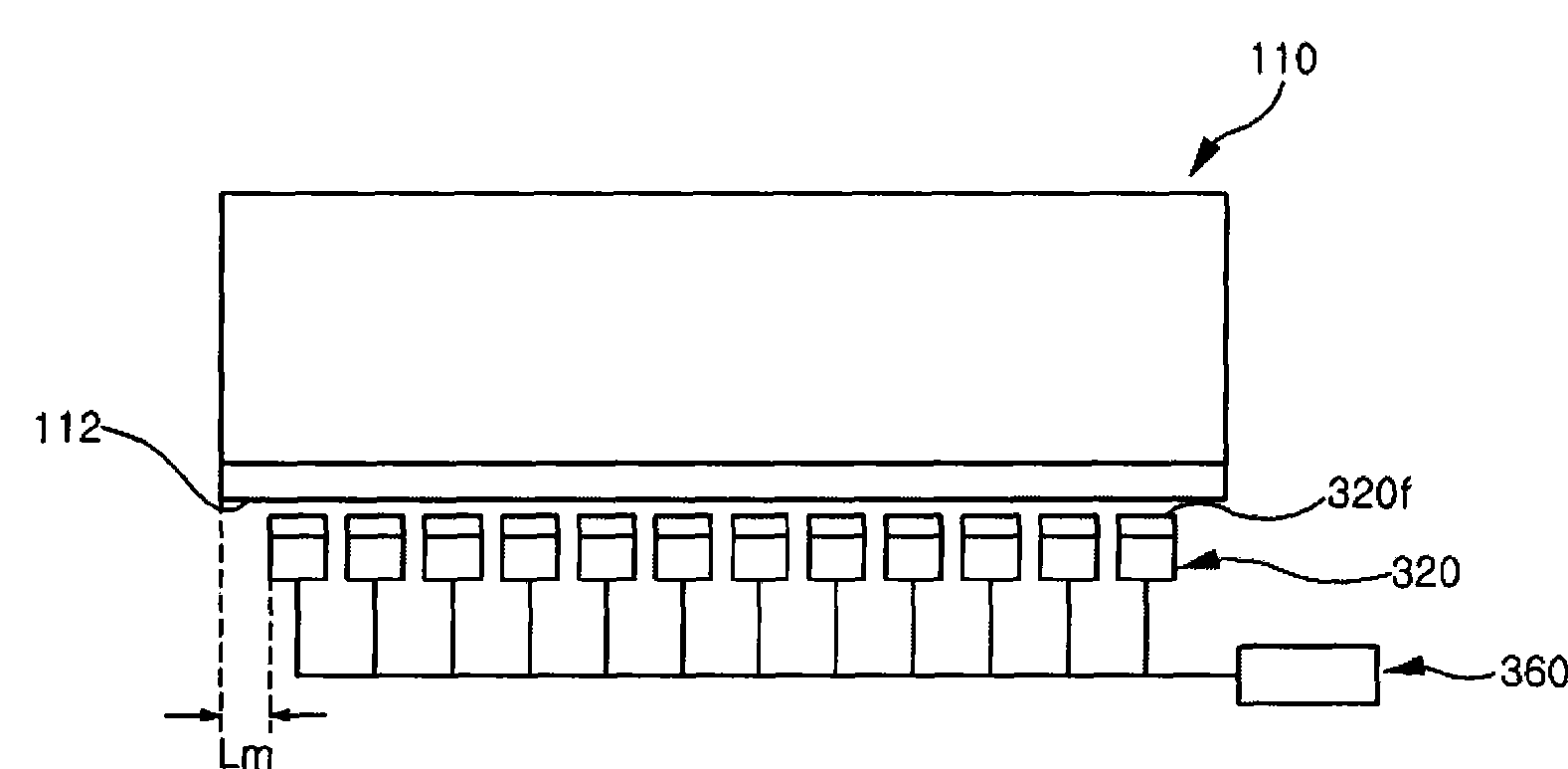

The invention relates to a device and a method used for measuring the injection evenness of a photoresist injected by a slit nozzle of a substrate coating apparatus, and according to the transverse injection evenness measurement apparatus of the slit nozzle provided by the invention, the invention comprises a plurality of fluid pressure measurement units which are provided with detection surfacesthat are opposite to an injection outlet of the slit nozzle, and the fluid pressure measurement units are arranged horizontally along the slit nozzle.

Description

Device and method for measuring lateral spray uniformity of slit nozzle technical field The invention relates to a device and a method for measuring the lateral spraying uniformity of photoresist ejected from a slit nozzle (Slit Nozzle) of a substrate coating device (Substrate Coating Apparatus). A device and method for lateral spraying uniformity of photoresist sprayed out along the lateral direction of a slit nozzle during resist resisting. Background technique Usually, when manufacturing a liquid crystal display device, process errors mainly occur in a photolithography process using a photoresist (Photoresist). If the photoresist is not uniformly coated, differences in resolution, circuit line width, and reflectivity differences occur in subsequent processes, causing defects directly reflected on the screen. Recently, there has been a demand to shorten the process time required to coat a photoresist on a substrate. Accordingly, it is necessary to study a method of un...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/16G02F1/1333

CPCB05C11/00B05C5/0254G03F7/16

Inventor 赵康一

Owner K C TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com