Device for determining and/or monitoring a volumetric and/or mass flow

A mass flow and volume technology, applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., can solve the problems of measurement value deviation and achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

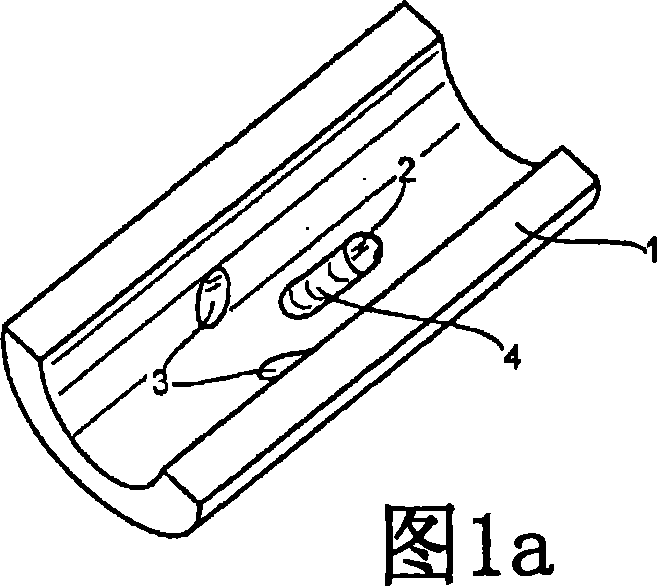

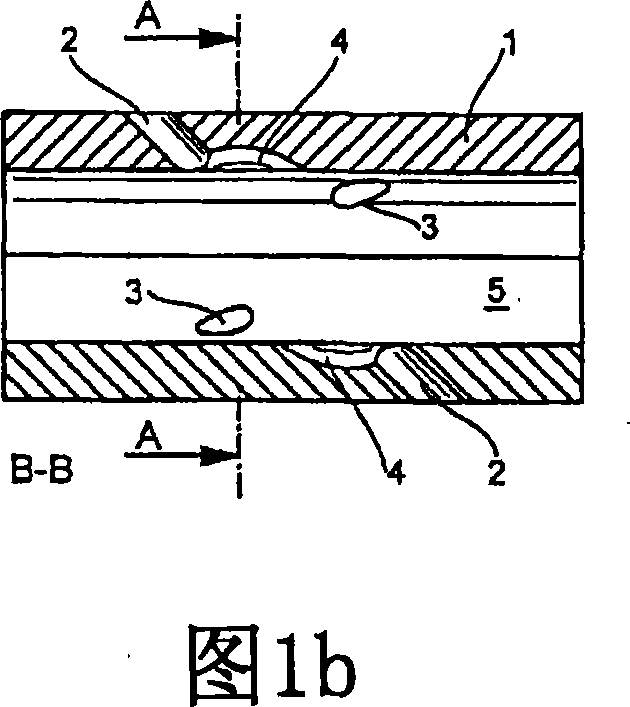

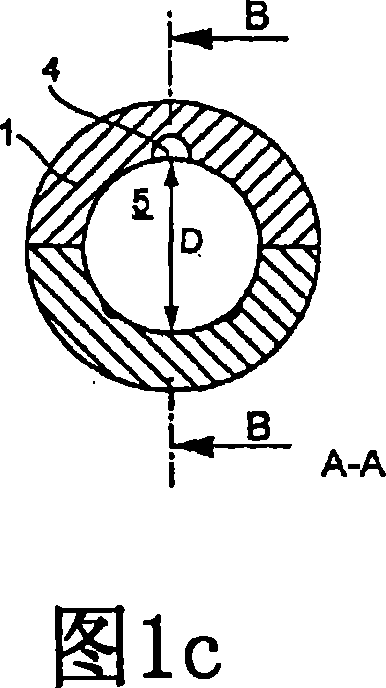

[0074] Fig. 1 to Fig. 9 are nine advantageous structural schematic diagrams of the online flowmeter 10 of the present invention. The flow meters 10 shown each comprise three measuring paths, ie acoustic paths. The volume or mass flow is preferably determined by the travel time difference method. The invention can in principle be applied to each ultrasonic flow meter 9 , 10 completely independently of the chosen measurement or analysis method. Even though only a flow meter with at least two ultrasonic sensors is described below, the ultrasonic flow meters 9 , 10 can also be designed with only one ultrasonic sensor 7 or with an optimized sensor housing for an acoustic path.

[0075] Figures 1a to 9a each show a top view of a cut-away measuring tube 1 according to the inventive concept. Each of the measuring tubes includes 3 bores with an at least partially optimized sensor housing 4 . In the example shown, the deformation 4 penetrates into the tube wall of the measuring tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com