Method for on-line detecting cloth evenness indices

A detection method and uniformity technology, applied in the field of cloth uniformity index online detection, can solve problems such as hindering diagnosis and analysis

Active Publication Date: 2010-08-11

BAOSHAN IRON & STEEL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to wavelength limitations, saturated sites appear in the high temperature section, hindering diagnostic analysis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

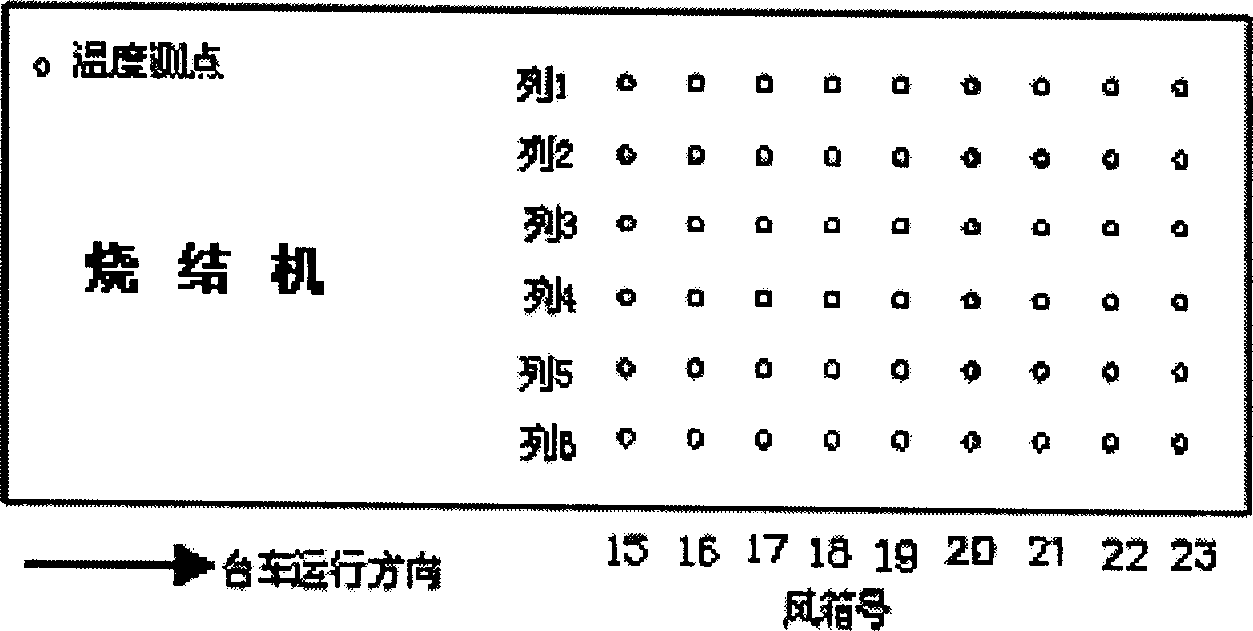

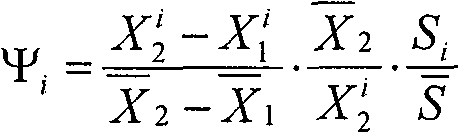

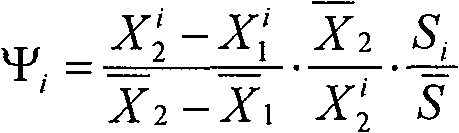

The invention discloses an on-line testing method of cloth even condition of cloth bed in the sintering manufacturing course, which is characterized by the following: assembling multiple thermocouples among each waste gas bellow at middle back part of sintering machine and at each bellow evenly; forming the temperature testing array of the sintered waste gas; establishing the plane temperature field of waste gas temperature of sintering machine; obtaining the character information through analyzing on-line temperature field; proceeding quantitative estimation for cloth uniformity; providing and defining the uniformity index of the sintered cloth as well as the mathematical model of the index. The invention realizes the on-line quantitative analysis of uniformity condition of composite material bed, which provides criterion to control the sintering material on the machine.

Description

(1) Technical field The invention relates to an online detection method for the uniform state of the material bed in the sintering production process. (2) Background technology Whether the sintering mixture is evenly distributed on the trolley directly affects the output, quality and energy consumption of sintering ore. Uniform material distribution is one of the main goals of the automatic control of the sintering system. Due to the continuity and long lag characteristics of the sintering process, once the mixture is distributed to the sintering machine, it cannot be adjusted again. Whether the distribution is uniform can only be judged by the manual experience of the operator at the tail of the sinter bed, and the results of the analysis and judgment are fed back to the automatic control system. This feedback method of production result information seriously restricts the basic automatic control. performance of the system. The online monitoring of sinter quality general...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N25/20G06F19/00F27D3/00G01B21/30

Inventor 马洛文张宗旺毛晓明陈九余韩俊潘安俊王跃飞辛发弟

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com