Western style water washing closet

A water-washing toilet, Western-style technology, applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of difficulty in flowing into the bedpan, easy generation of dirt, etc., and achieve the effect of preventing odor and great industrial value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

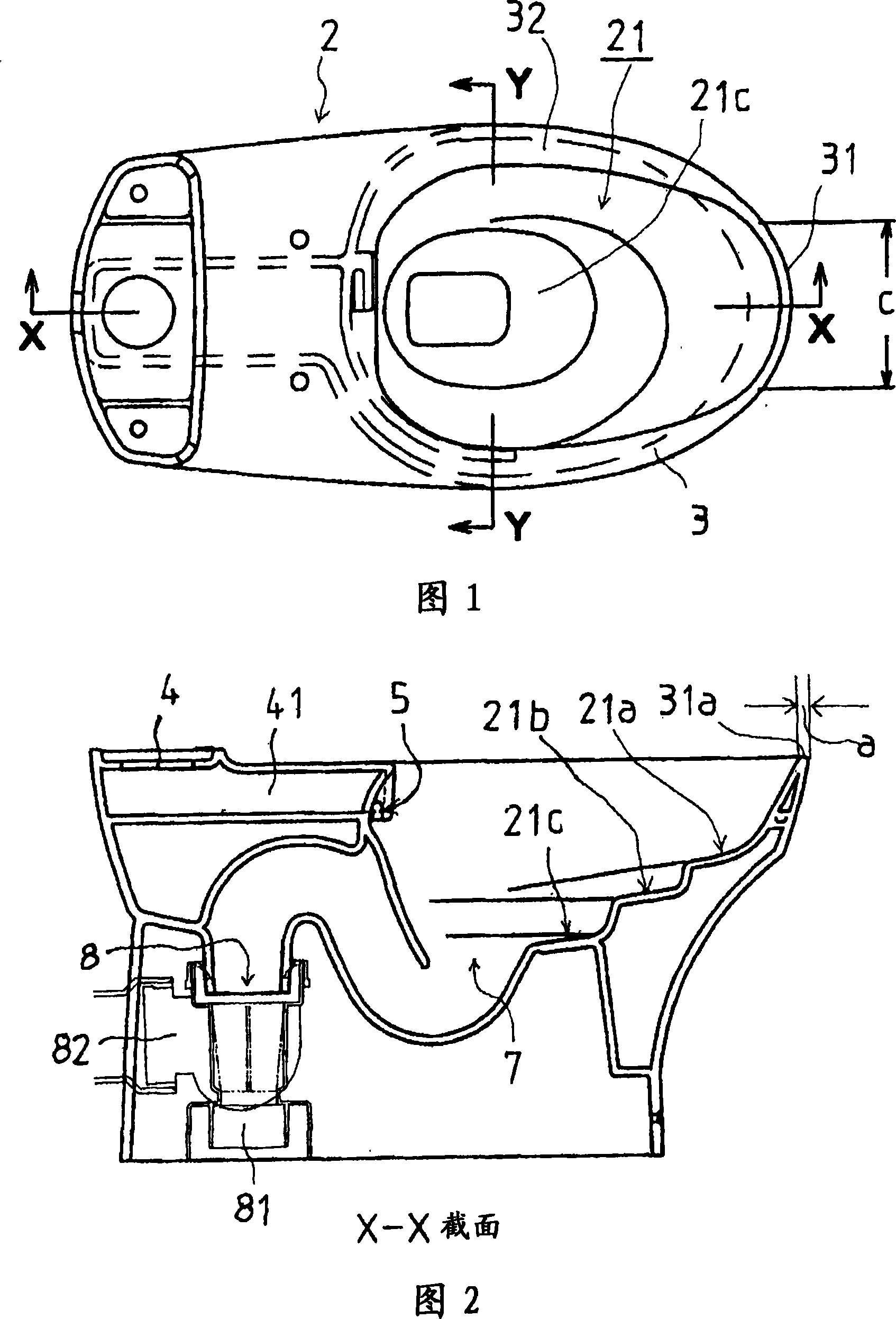

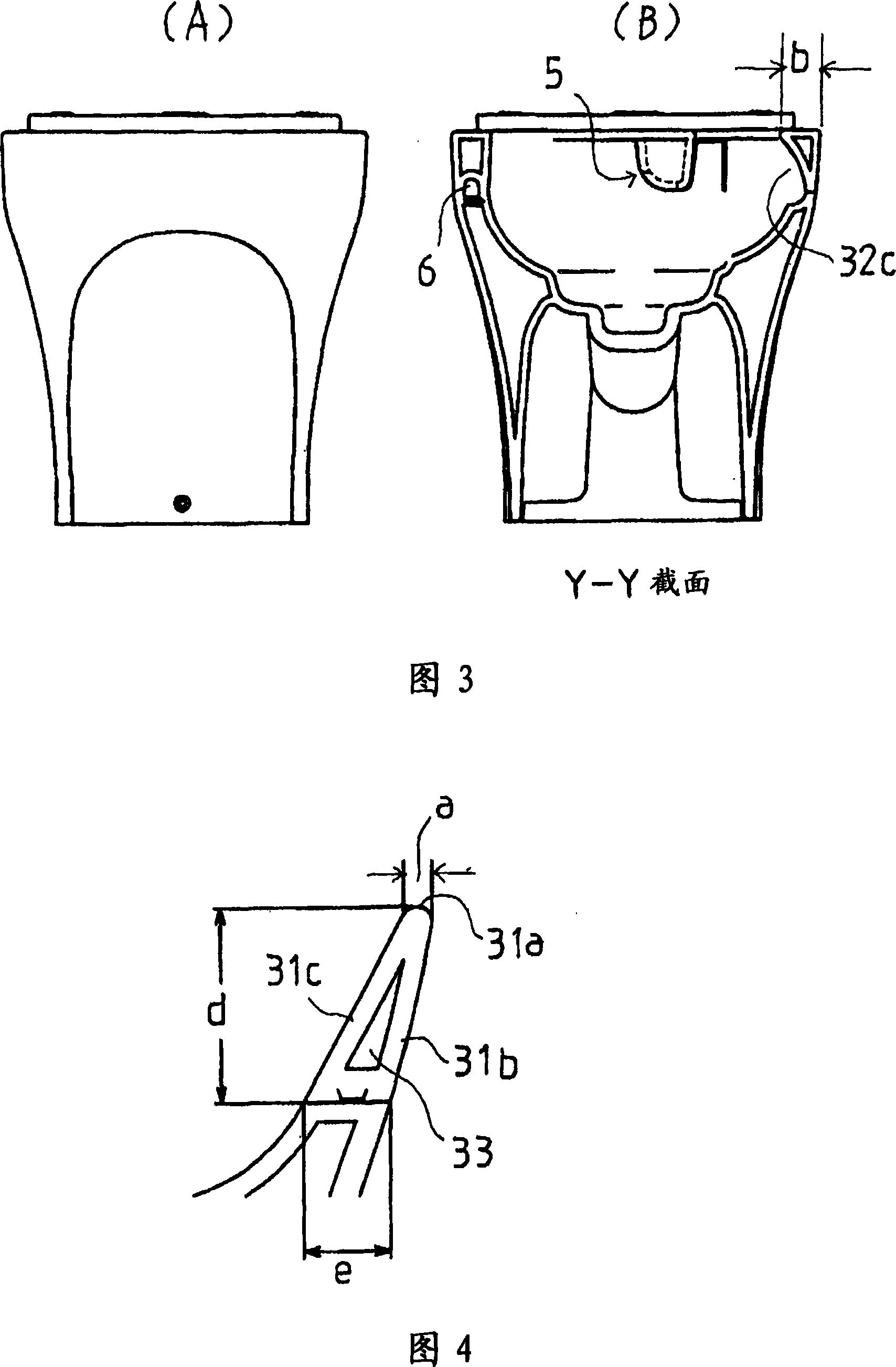

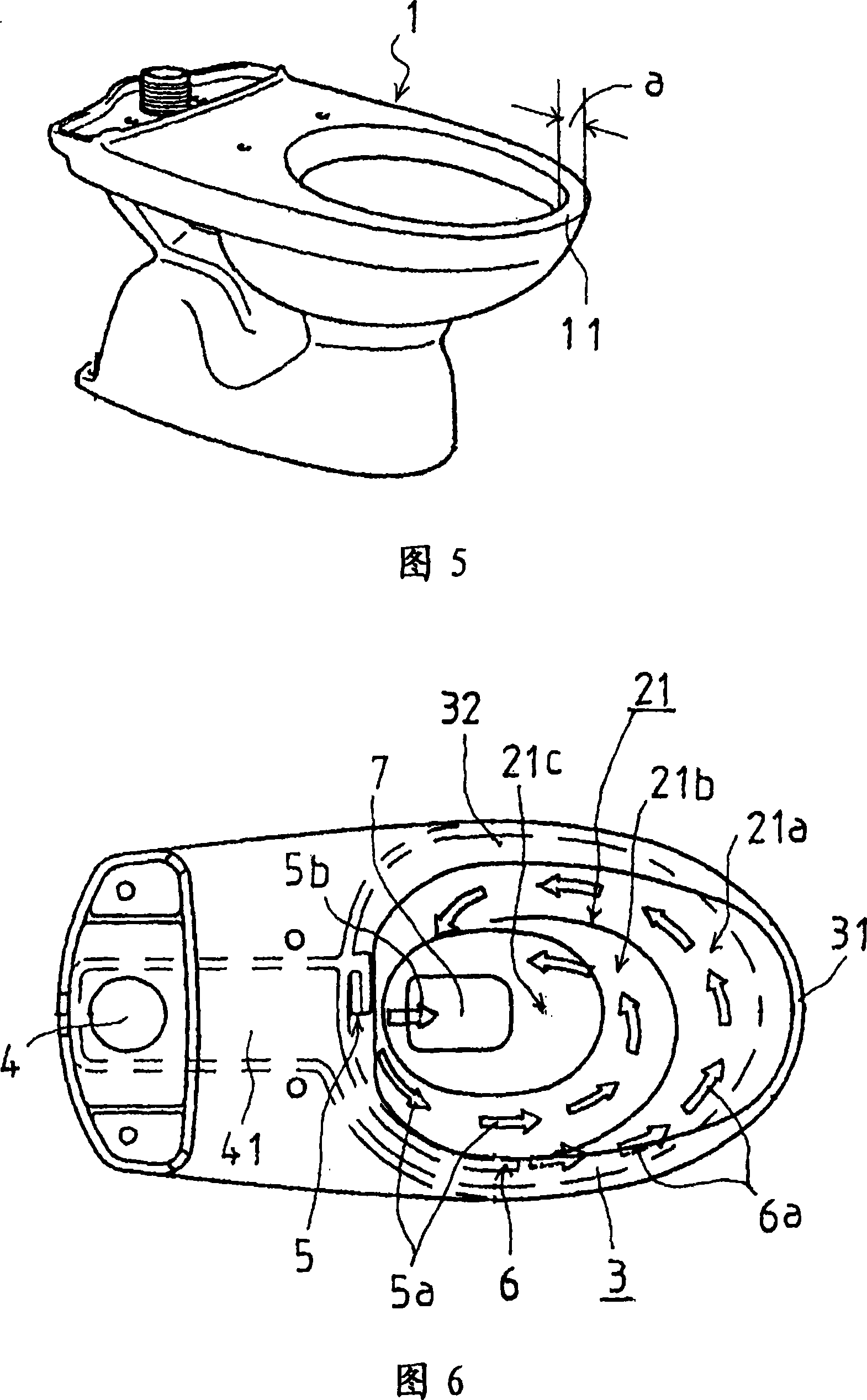

[0018] Next, an embodiment of a western-style flush toilet according to the present invention will be described with reference to FIGS. 1 to 4 .

[0019] The present invention is characterized in that, in the mouth edge upper portion 31a of the toilet bowl portion 21 of the Western-style flush toilet 2, the thickness in the horizontal direction of the front portion 31 is made smaller than the thickness of the side portions 32 (usually about 35 mm to 45 mm in thickness). , Specifically, at first, as shown in Fig. 1, 2, the present invention will be installed on the seat type Western-style water closet on the toilet floor as object.

[0020] And, wash water is stored in the bedpan part 21, and the wash water flows out through the drainage operation after defecating. The thickness: refer to FIG. 2) is smaller than the thickness b (thickness in the horizontal direction: refer to FIG. 3) of the side portion 32. In this case, in the front portion 31 whose lateral width c (refer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com