Axial gap motor

一种轴向间隙、类型的技术,应用在电气元件、机电装置、带有静止电枢和旋转磁体的同步电动机等方向,能够解决不能获得高输出等问题,达到高扭矩输出、实现小型化、高输出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Embodiments of the present invention will be described by referring to the drawings.

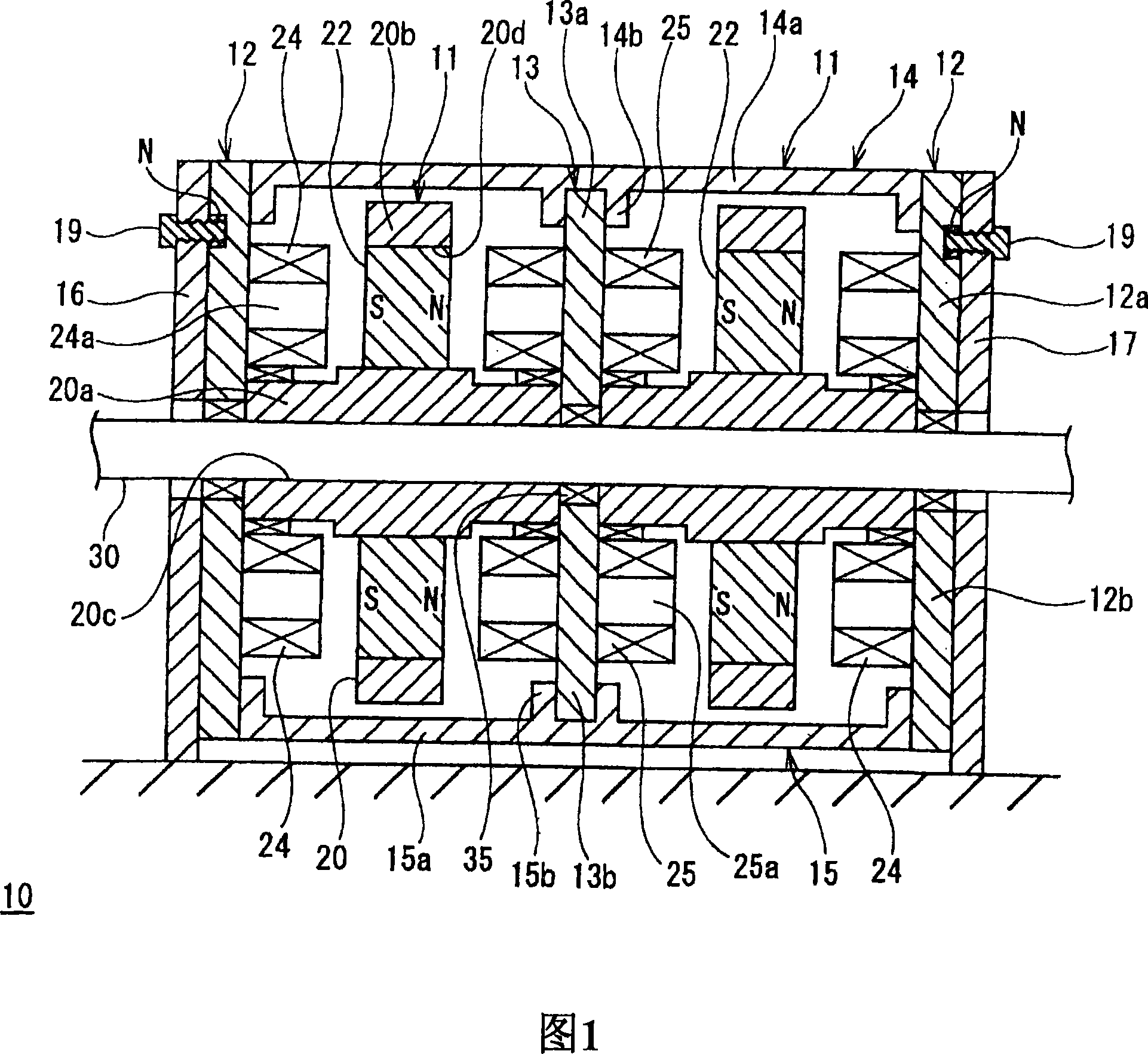

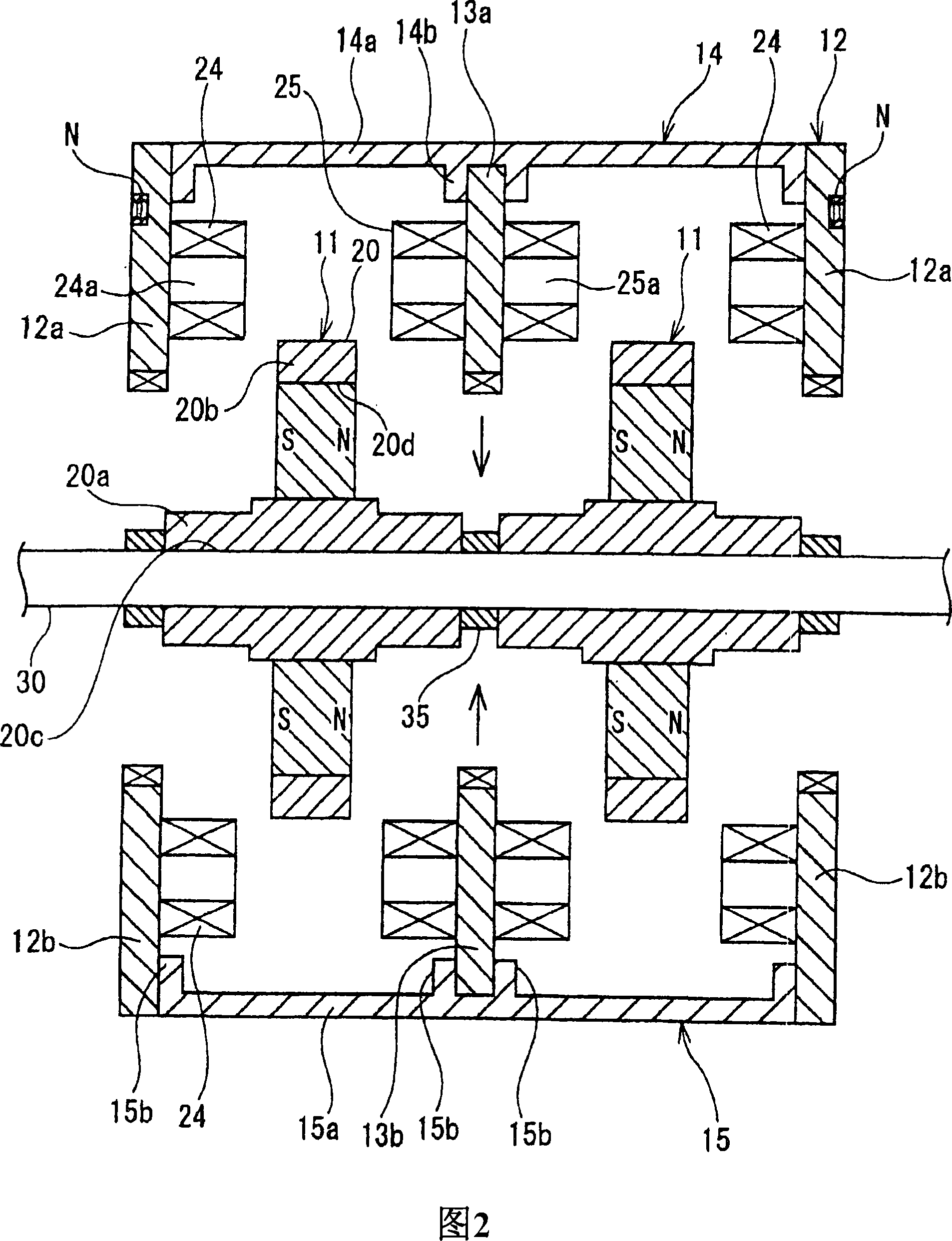

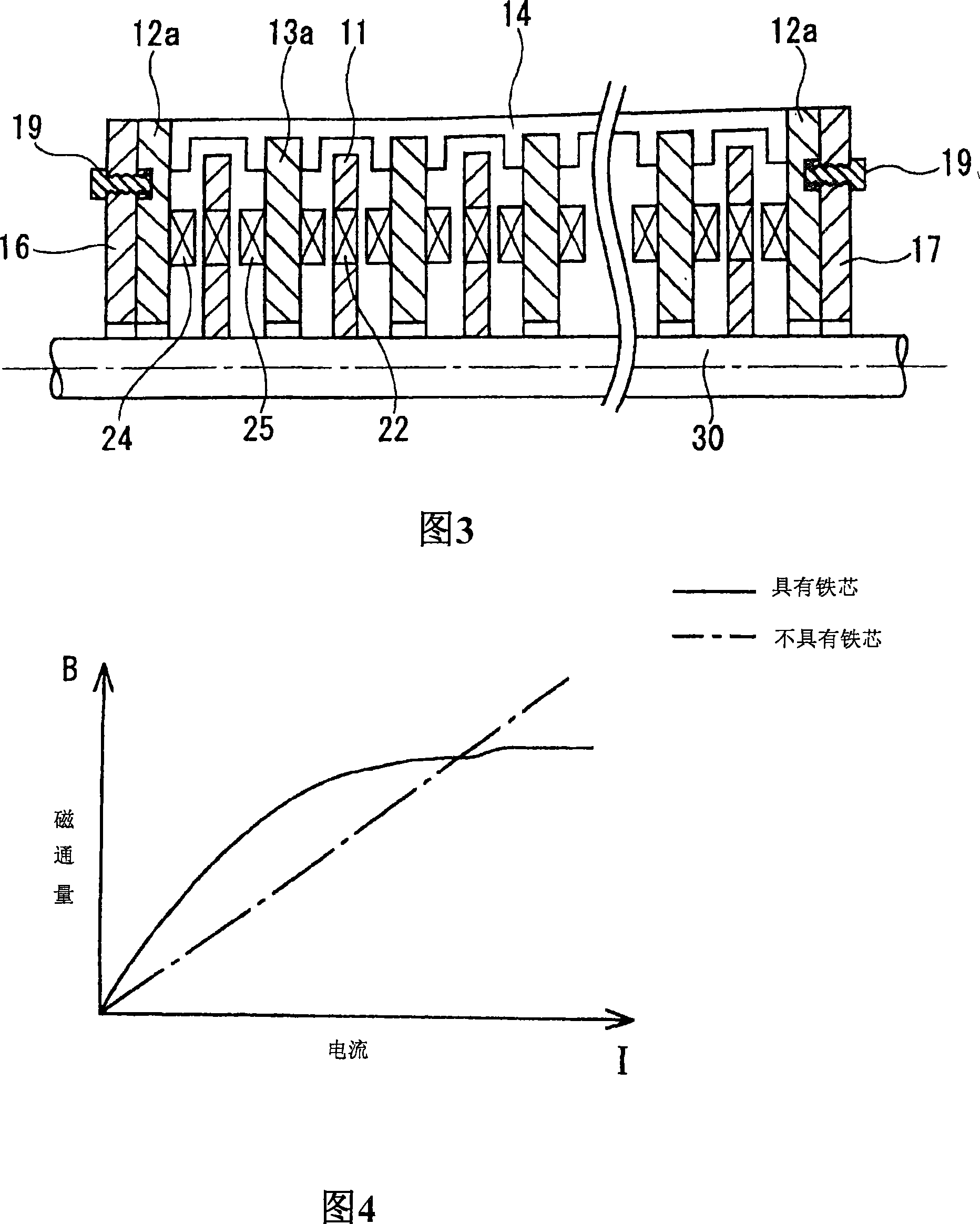

[0094] 1-3 show a series-coupled synchronous axial gap type electric machine 10 according to a first embodiment of the present invention. Furthermore, FIGS. 1 and 2 show an arrangement in which two rotors 11 , stators 12 at both axial ends, and an intermediate stator 13 are alternately arranged in the axial direction of the rotary shaft 30 for simplicity of illustration. However, as shown in FIG. 3 , a plurality of intermediate stators 13 are provided, and rotors 11 are disposed between adjacent stators 12 and 13 and between adjacent stators 13 and 13 , respectively.

[0095] The rotor 11 is fixed to the rotary shaft 30, and the stators 13 and 12 are arranged on both sides of the rotor 11 in the axial direction thereof with a required air gap. The stators 12 and 13 are connected to each other by upper and lower connection tools 14 and 15 , and the stators 12 at both axial ends are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com