Multi-gas distribution injector for chemical vapor deposition reactors

A chemical vapor deposition and gas distribution technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as output reduction and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

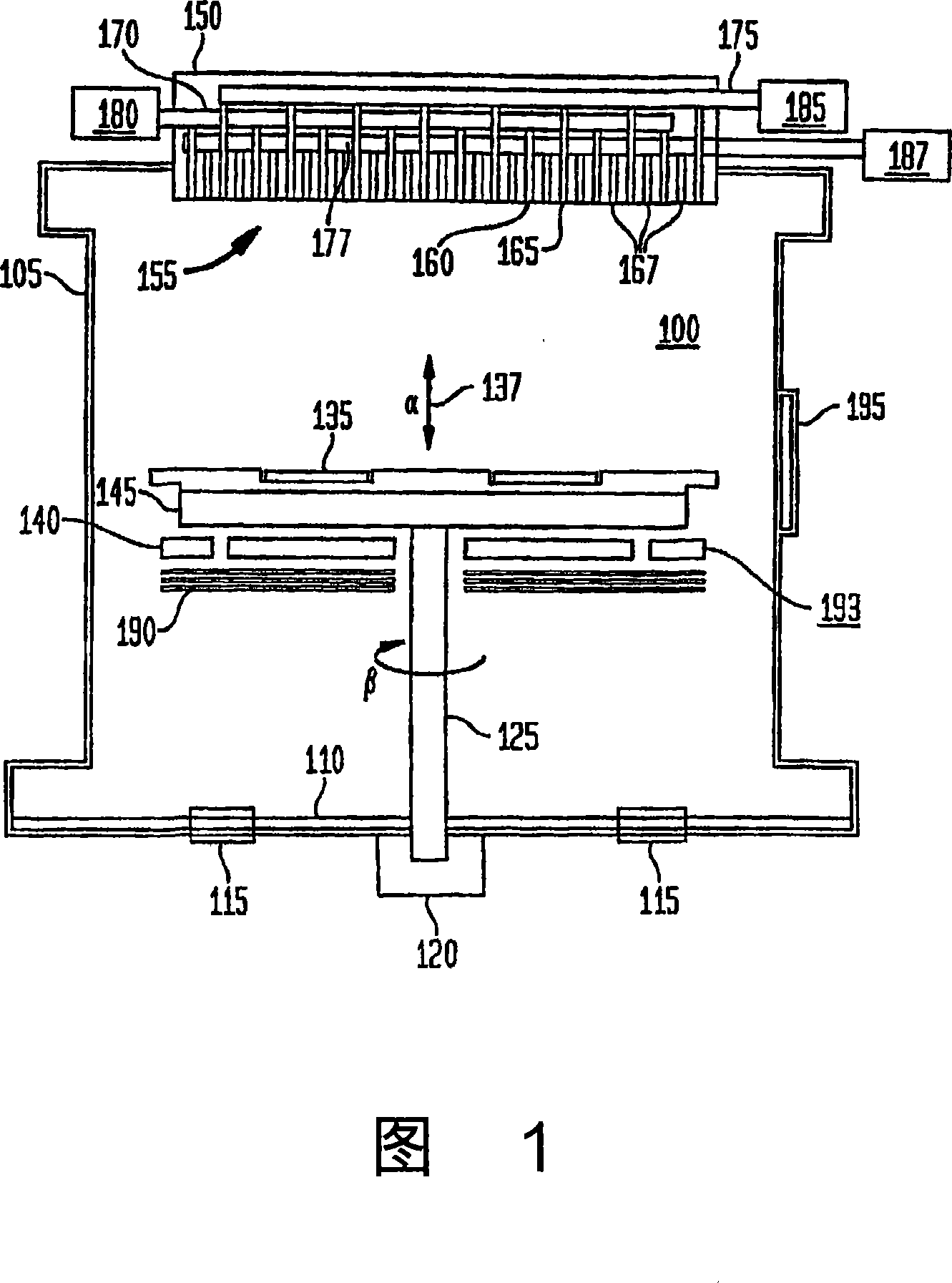

[0058] Referring now to the drawings, in which like numerals refer to like elements, Figure 1 shows a rotating disk reactor including a multi-gas injector according to an embodiment of the present invention.

[0059] As shown schematically in FIG. 1, the apparatus comprises a cylindrical reaction chamber made of stainless steel walls 105, a bottom plate 110, exhaust ports 115, and a vacuum through-hole feedthrough that seals the rotation of a rotating mandrel 125. 100, a wafer carrier 130 with a base wafer 135 is mounted on top of the mandrel. The wafer carrier is rotatable about an axis 137 (α) coaxial with the cylindrical chamber 100 at a predetermined rotational speed (β).

[0060] A heating base 145 is heated by a set of heating elements 140. The heating elements are usually made of refractable metals, such as but not limited to molybdenum, tungsten or rhenium, or non-metals such as graphite, which can be divided into multiple Heated area. The metal used for the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com