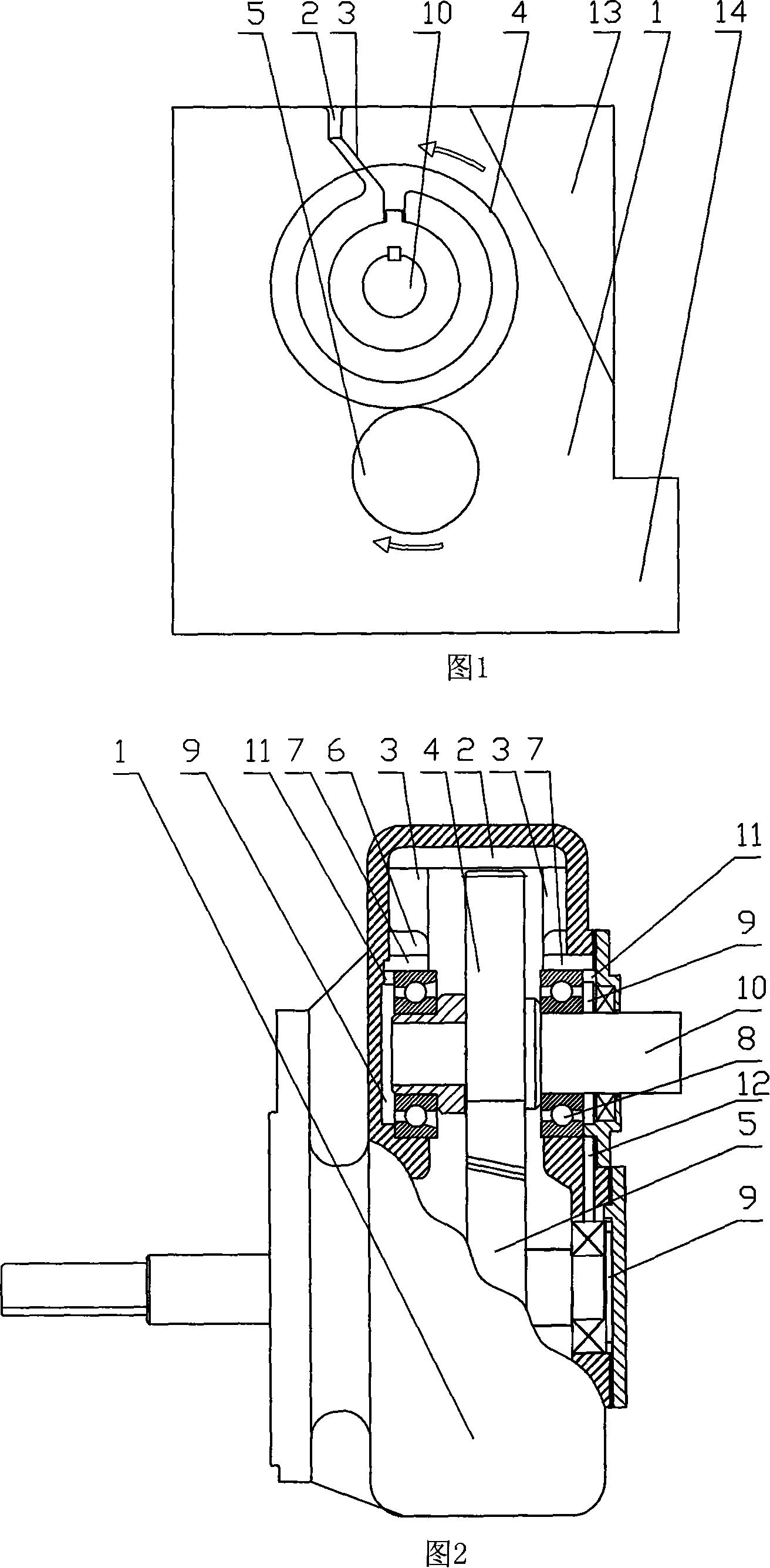

Gear self-lubricating device for gear box

A gearbox and self-lubricating technology, which is applied in the direction of gear lubrication/cooling, can solve the problems of complex forced lubrication structure and poor splash lubrication effect, and achieve the effect of simple structure, simple installation and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention includes deflectors, guide grooves, oil inlets, lubricating oil chambers, and connecting grooves, wherein the deflectors include transverse deflectors arranged on the top surface of the inside of the gearbox casing and respectively arranged on the gear box There are two vertical baffles on the two side end surfaces inside the box, and the baffles are arranged horizontally on the upper gear bearing seat. The two ends of the horizontal baffles are respectively connected to the upper end of each vertical baffle. The lower end of the deflector is connected to the outer end of the diversion groove on the corresponding bearing, and the four lubricating oil chambers are respectively arranged between the bearing chambers of the bearings on both sides of the upper gear and the lower gear and the outer end surface of the bearing. The inner end opens to the upper end of the corresponding oil inlet, and the lower end of the oil inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com