Suction powder feeding system

A powder feeding and inhalation technology, which is applied in the inhalation powder feeding system and the field of short-distance transportation of dry powder materials or granular materials, can solve the problem of not being able to absorb bagged powder, etc., and achieves simple structure, low modification cost, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

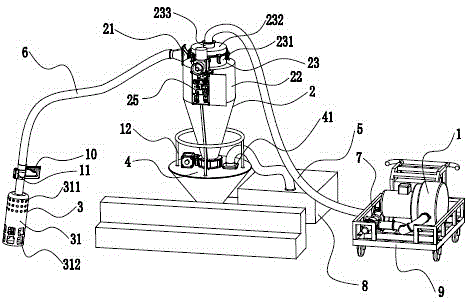

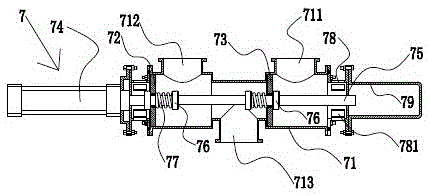

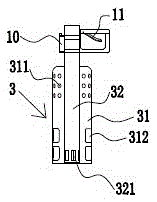

[0027] The suction type powder feeding system provided by this embodiment, such as Figure 1-Figure 4 As shown in , it includes an air power source 1, a gas-solid separation device 2 connected to the air power source 1 through a connecting pipe 5, a support plate 4 installed under the gas-solid separation device 2, and a suction gun 3. The feed port of the solid separation device 2 communicates with the suction gun 3 through the feed pipe 6, the discharge port of the gas-solid separation device 2 communicates with the hopper under the support plate 4, and a gas-solid separation device 2 is provided with a The dust removal filter element 24 also includes a back-blowing cleaning system for removing fine powder on the dust removal filter element 24, and the back-blowing cleaning system includes a pneumatic reversing valve 7 arranged between the air power source 1 and the connecting pipeline 5, and The feed check valve 21 at the feed port of the gas-solid separation device 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com