Camera motor

A motor and camera technology, applied in the field of camera motors with auto-focus structure, can solve the problems of time and power consumption, complex lens structure, and cost, and achieve the effect of low cost and simple focus structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

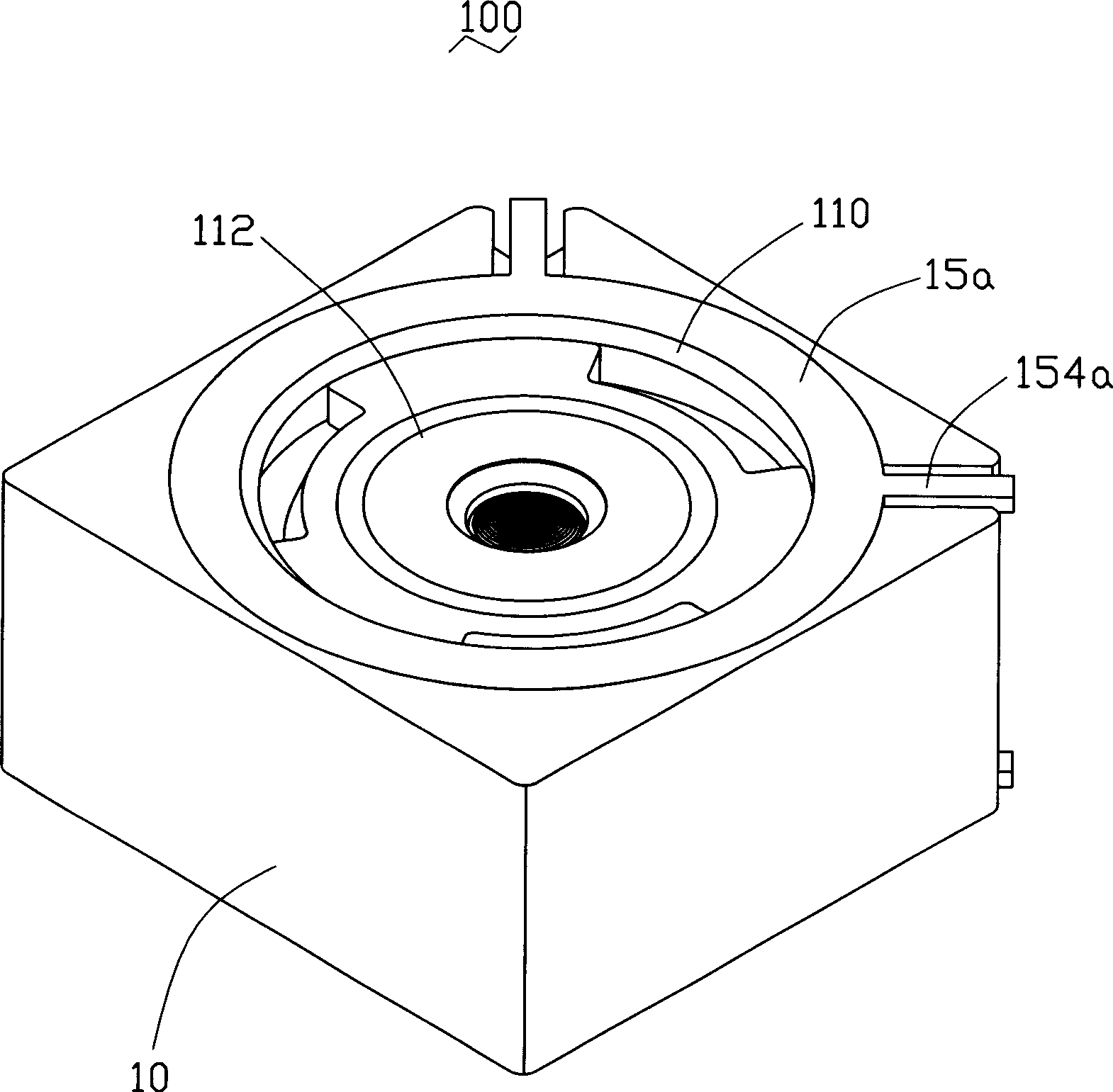

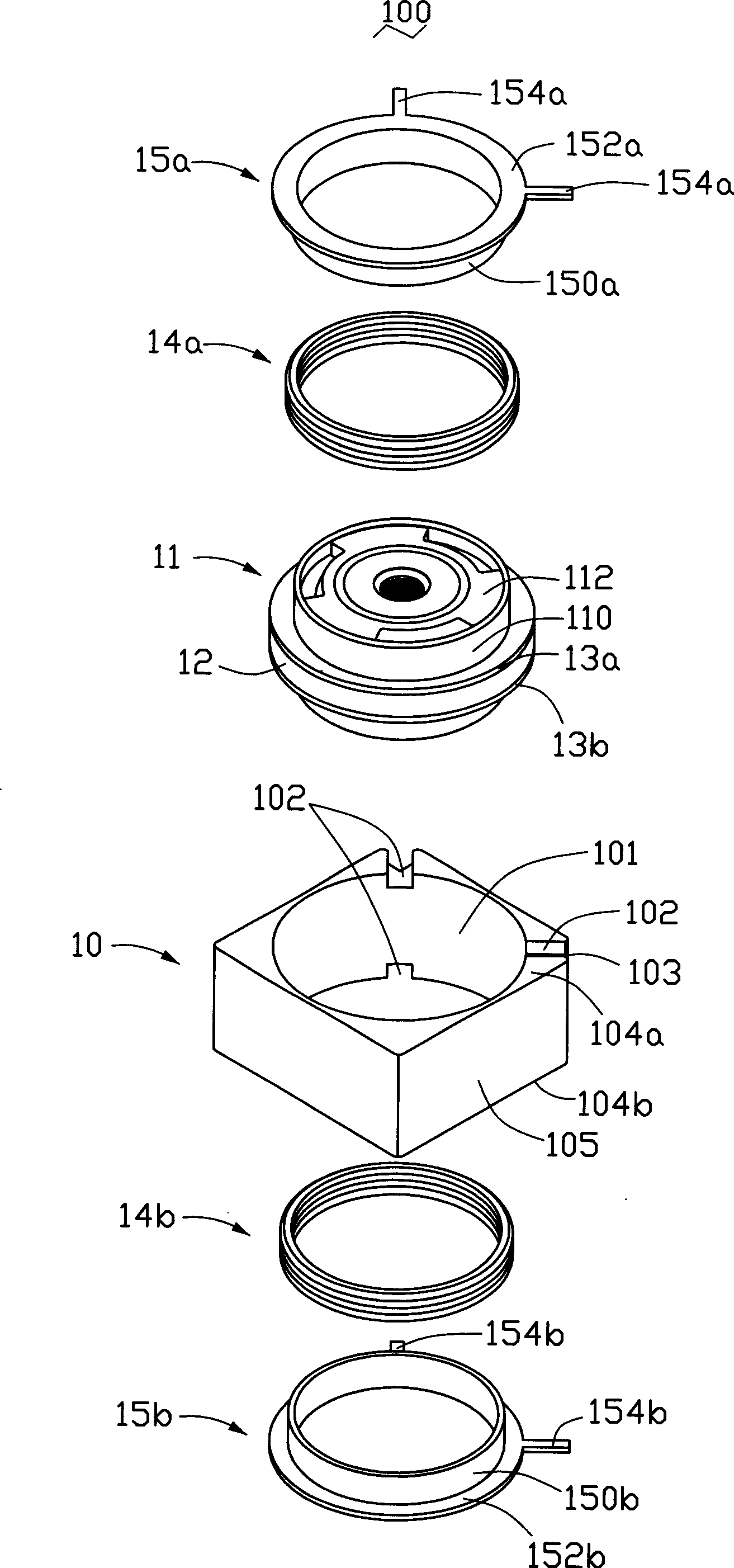

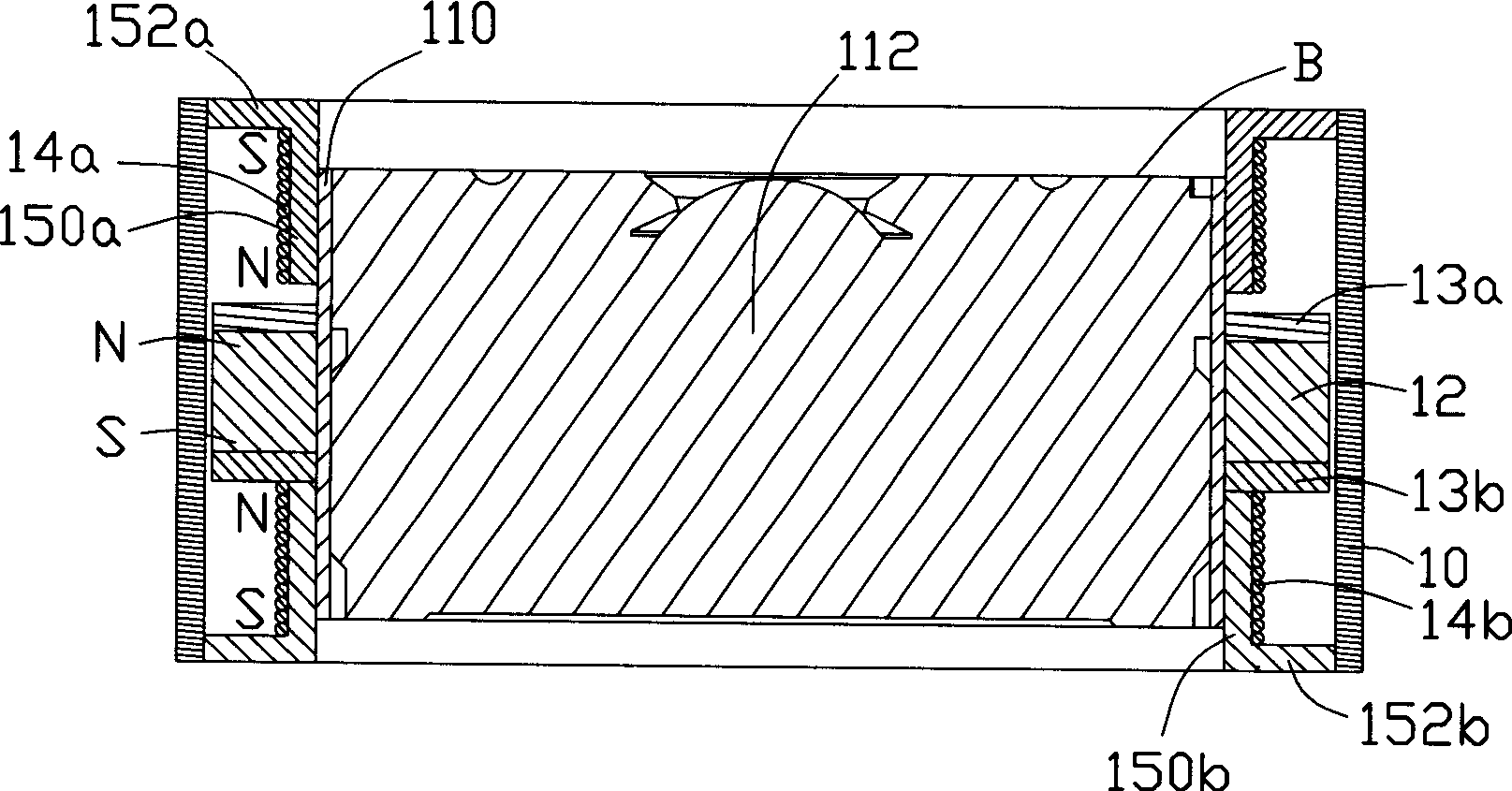

[0016] Please refer to figure 1 and figure 2 , the camera motor 100 of the present invention is an autofocus structure, which is applied in a digital camera, and can be in a far focus B (such as image 3 shown) and a near focal point A (such as Figure 4 As shown), it includes a casing 10, a lens group 11 placed in the casing 10, a permanent magnet 12 set on the lens group 11, upper and lower coils on both sides of the permanent magnet 12 Seats 15a, 15b, and upper and lower coils 14a, 14b respectively wound on the coil seats 15a, 15b in a certain direction.

[0017] The shell 10 is in the shape of a square column, and a cylindrical accommodating space 101 is formed inside to accommodate the lens group 11, the permanent magnet 12, and the upper and lower coil holders 15a, 15b surrounded by the coils 14a, 14b. Two grooves 102 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com