Sectional type focusing lens module

A focus lens and segmented technology, which is applied in the field of segmented focus lens modules, can solve the problems of inconvenient assembly, increased lens module volume, and complex focusing structure of the lens module, etc., and achieves miniaturization and focusing structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

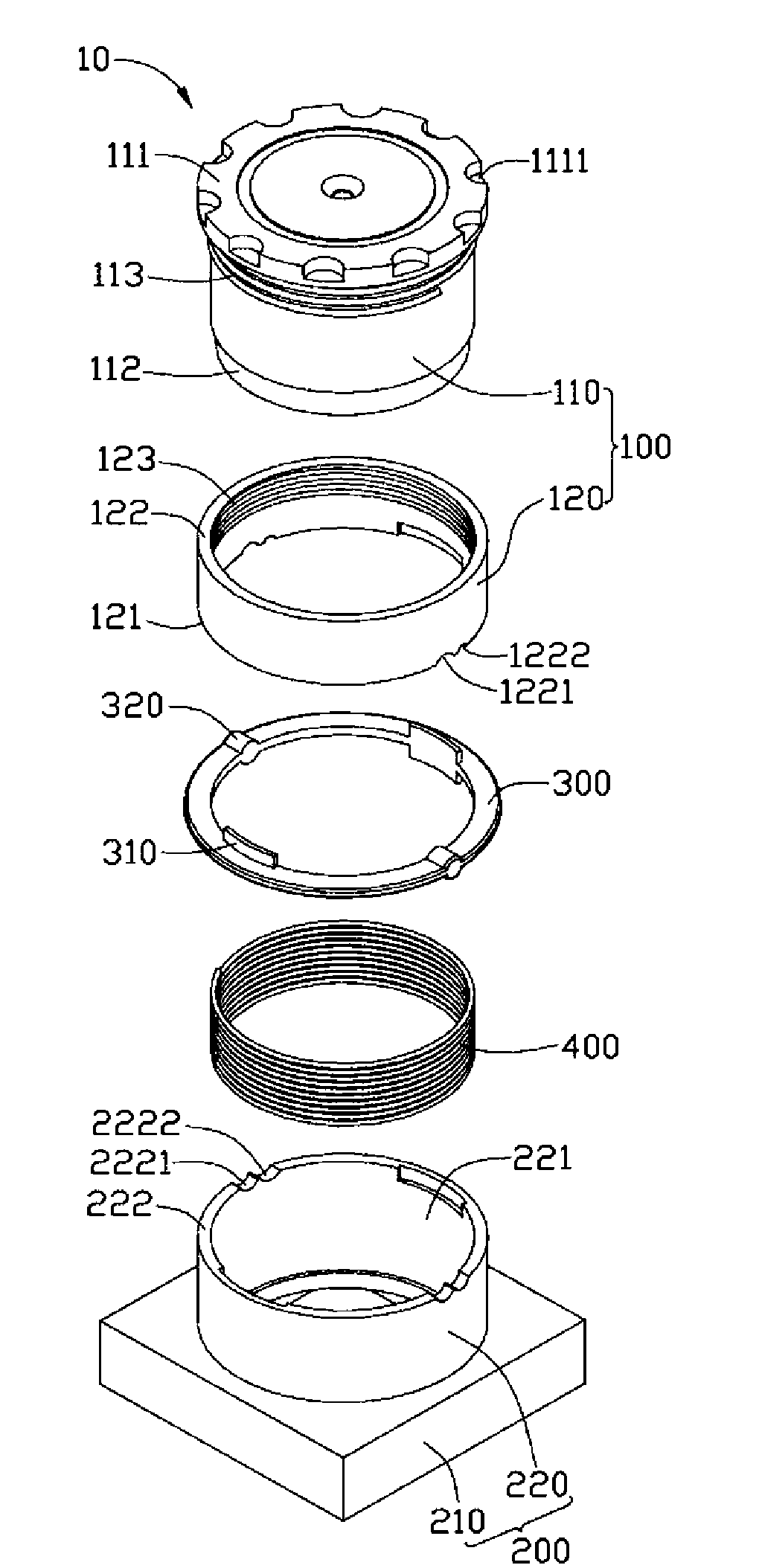

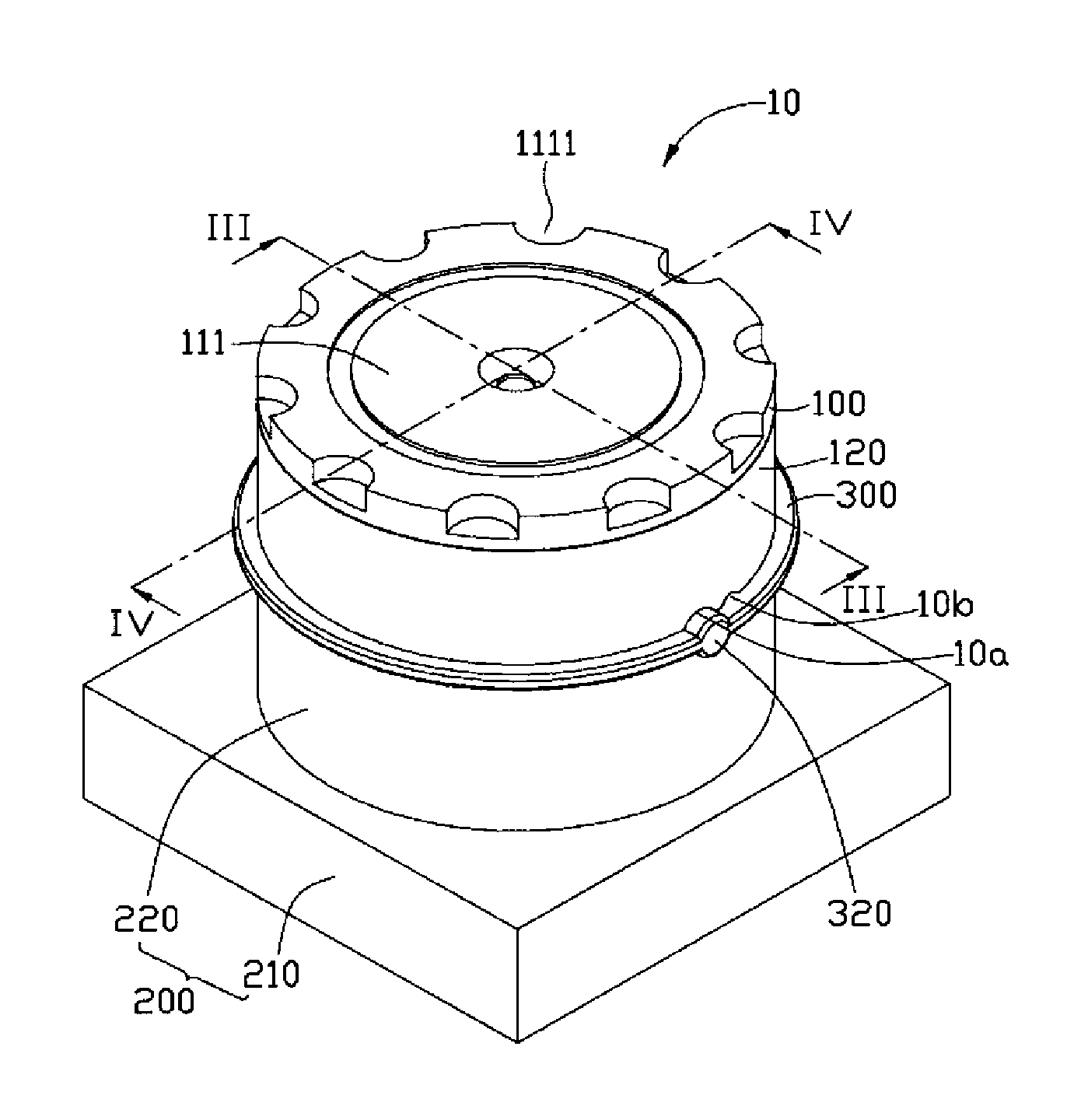

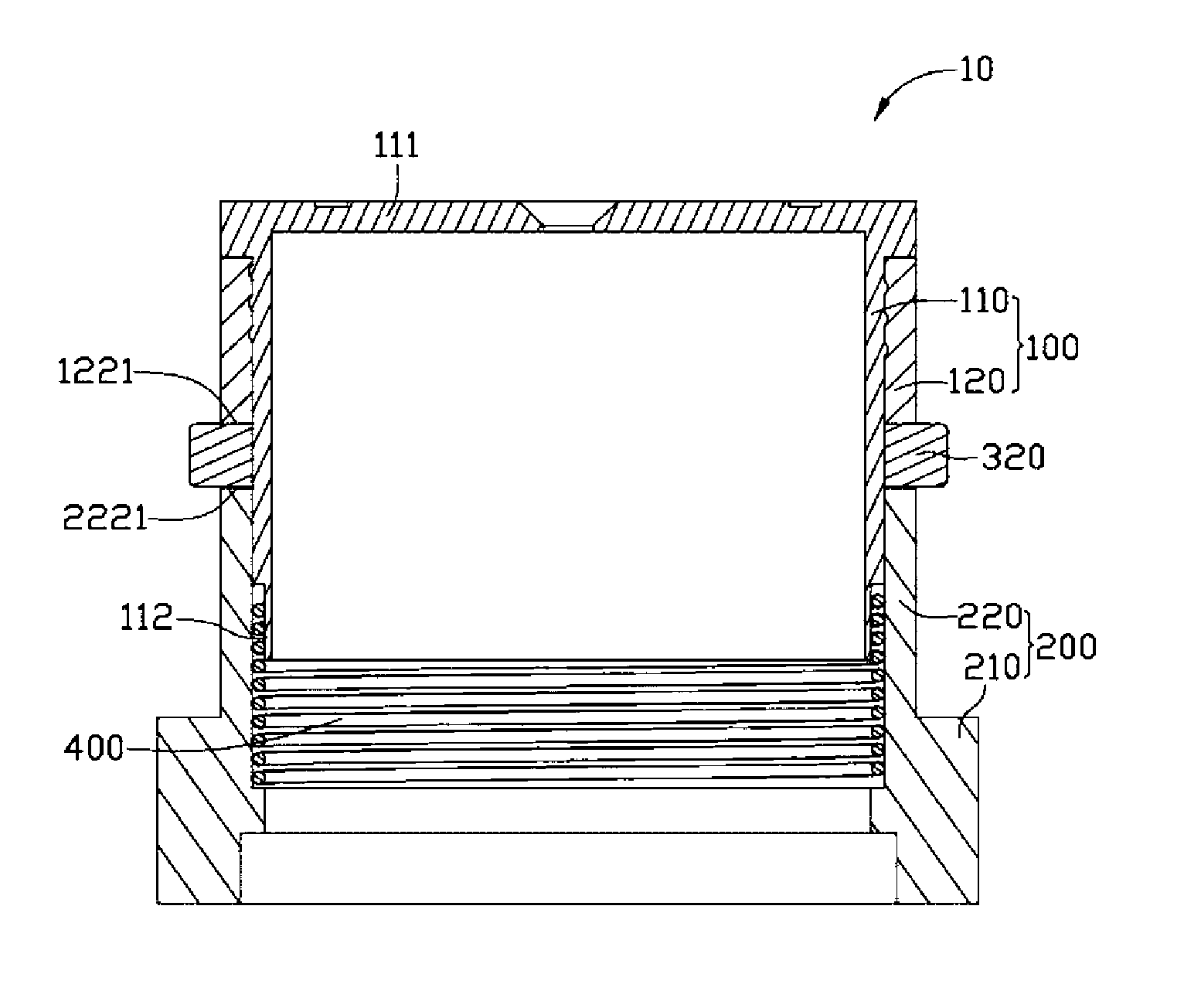

[0042] Please also refer to Figure 1 to Figure 4 , a segmented focus lens module 10 provided in the first embodiment of the present invention, which includes a lens barrel 100 , a lens mount 200 , a focus ring 300 and an elastic element 400 .

[0043] The lens barrel 100 includes an inner lens barrel 110 and an outer lens barrel 120 . The inner lens barrel 110 is in the shape of a cylinder, inside which accommodates elements such as lens groups, spacer rings and filters (not shown in the figure). The inner barrel 110 includes a first end 111 on the object side and a second end 112 on the image side. The first end 111 is in the shape of a disk, and its edge is evenly spaced with a plurality of grooves 1111, the grooves 1111 are used to facilitate the rotation of the inner lens barrel 110 to assemble the inner lens barrel 110 into the outer barrel 120. An external thread 113 is formed on a surface of the inner lens barrel 110 close to the first end 111 thereof.

[0044] The...

Embodiment approach 2

[0053] see Figure 5 The difference between the second embodiment and the first embodiment is that the top surface 222 of the mirror base 200 is provided with a third arc-shaped notch 2221 and a fourth arc-shaped notch 2222 with different depths in the direction of the optical axis. , the outer lens barrel 120' is not provided with an arc-shaped gap, and a protrusion 320' protrudes from the end surface of the focusing ring 300' opposite to the mirror base 200, and the protrusion 320' is in the shape of a half cylinder, and The axis is perpendicular to the optical axis.

[0054] When in use, turn the focus ring 300 ′, and the protrusion 320 ′ can slide between the third arc-shaped notch 2221 and the fourth arc-shaped notch 2222 formed on the top surface 222 of the mirror base 200 , and then drive the lens barrel 100 to move between two positions in the direction of the optical axis, thereby realizing split-end focusing of the lens module 20 .

Embodiment approach 3

[0056] see Image 6 The difference between the third embodiment and the first embodiment is that the bottom surface 121 of the outer lens barrel 120 is provided with a first arc-shaped notch 1221 and a second arc-shaped notch 1222 with different depths in the direction of the optical axis. The accommodating portion 220' of the mirror base 200 is not provided with an arc-shaped gap, and a protrusion 320'' protrudes from the end surface of the focus ring 300'' opposite to the outer lens barrel 120, and the protrusion 320'' It is in the shape of a half cylinder, and its axis is perpendicular to the optical axis.

[0057] When in use, turn the focusing ring 300 ″, the protrusion 320 ″ can slide between the first arc-shaped notch 1221 and the second arc-shaped notch 1222 formed on the outer lens barrel 120 , and then drive The lens barrel 100 moves between two positions in the direction of the optical axis, realizing split-end focusing of the lens module 30 .

[0058] Compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com