Cooling device

A technology of cooling device and pump device, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as the adverse effects of temperature adjustment of working machine tools, and achieve improved processing accuracy, economical processing, and reliable functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

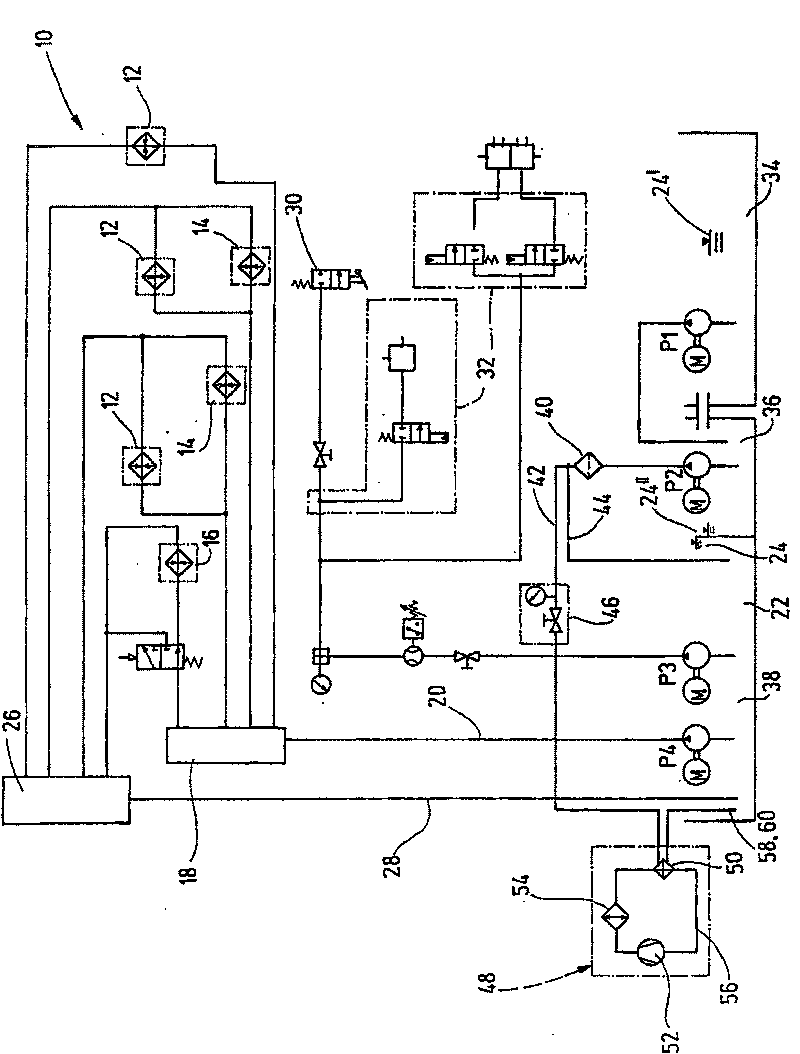

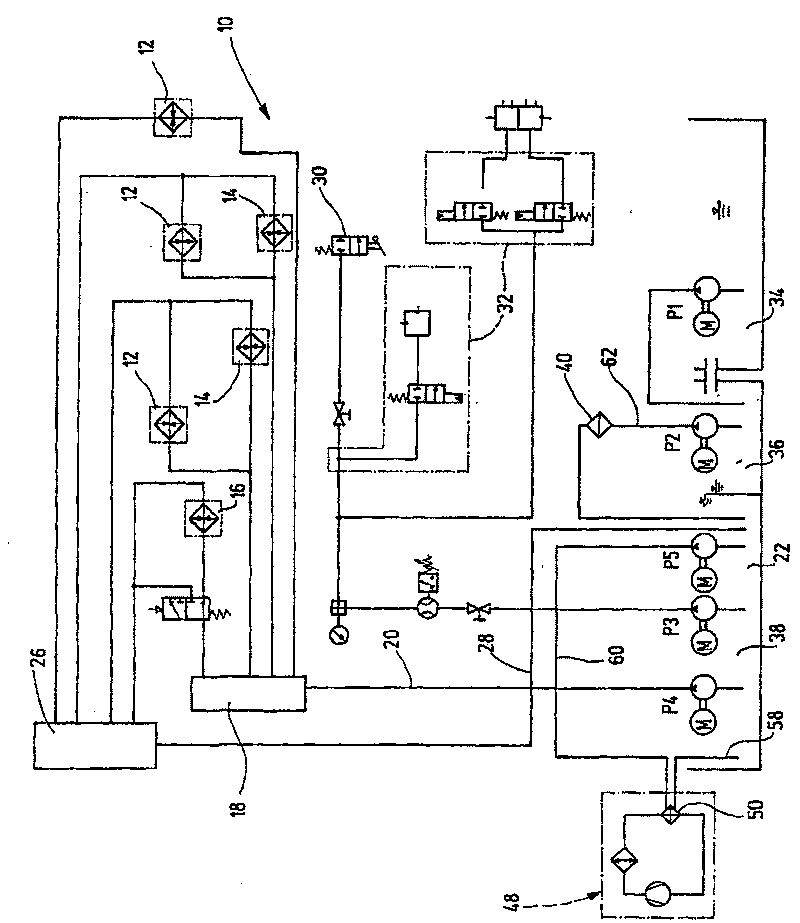

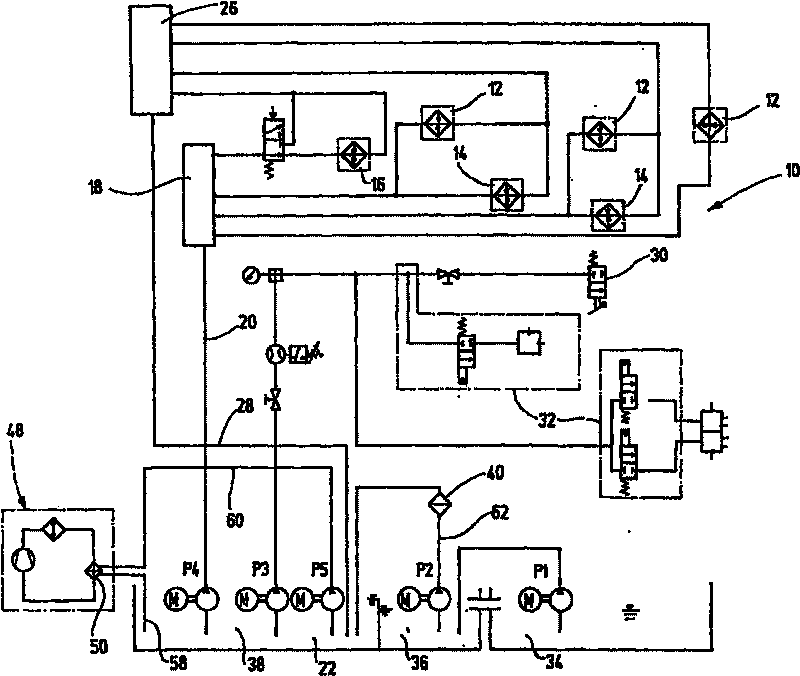

[0021] in the aid of figure 2 Before explaining the cooling device according to the invention in detail, the known structure according to FIG. 1 must first be explained in detail.

[0022] FIG. 1 shows a known cooling device for a machine tool in the form of a grinding machine generally indicated at 10 . The grinding machine 10 has three linear motors 12 as well as two axial motors 14 and a grinding spindle motor 16 for driving a grinding wheel (not shown). The further described motors 12 and 14 enable a five-axis grinding drive by means of which turbine blades or similar components can also be ground with high precision. The motors 12, 14 and 16 are supplied with fluid in the form of cooling lubricant from a clean tank 22 via a distributor 18, via a forward line 20 in the form of a fluid line, by means of a hydraulic pump P4. The possible level of cooling lubricant in the clean oil tank 22 is indicated symbolically by a level indicator 24 . The cooling lubricant delivered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com