Integrated machining fixing base

A fixed seat, integrated technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of uneven product processing accuracy, affect work efficiency, increase working time, etc., to shorten the processing time, improve Work efficiency and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

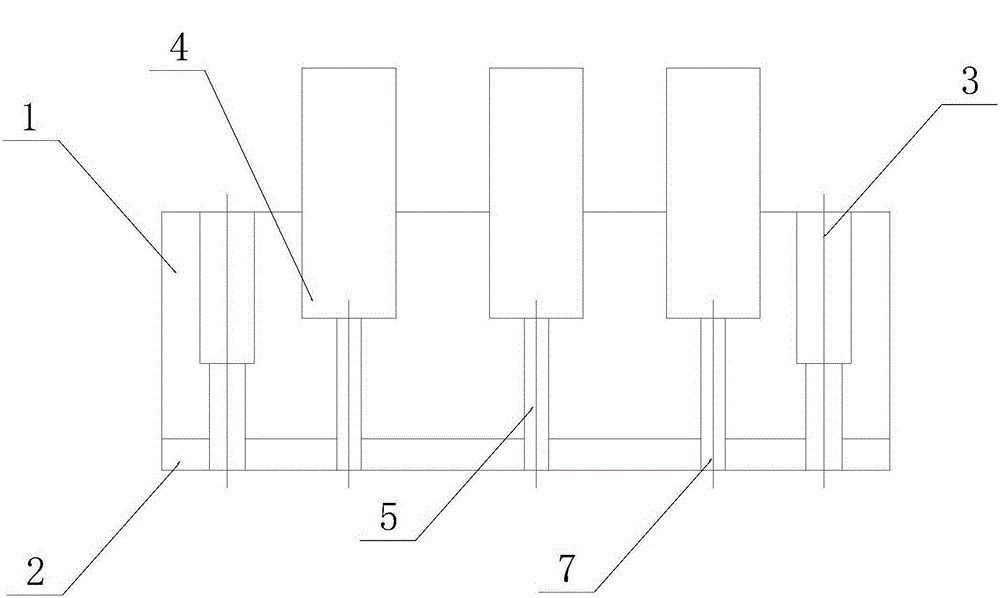

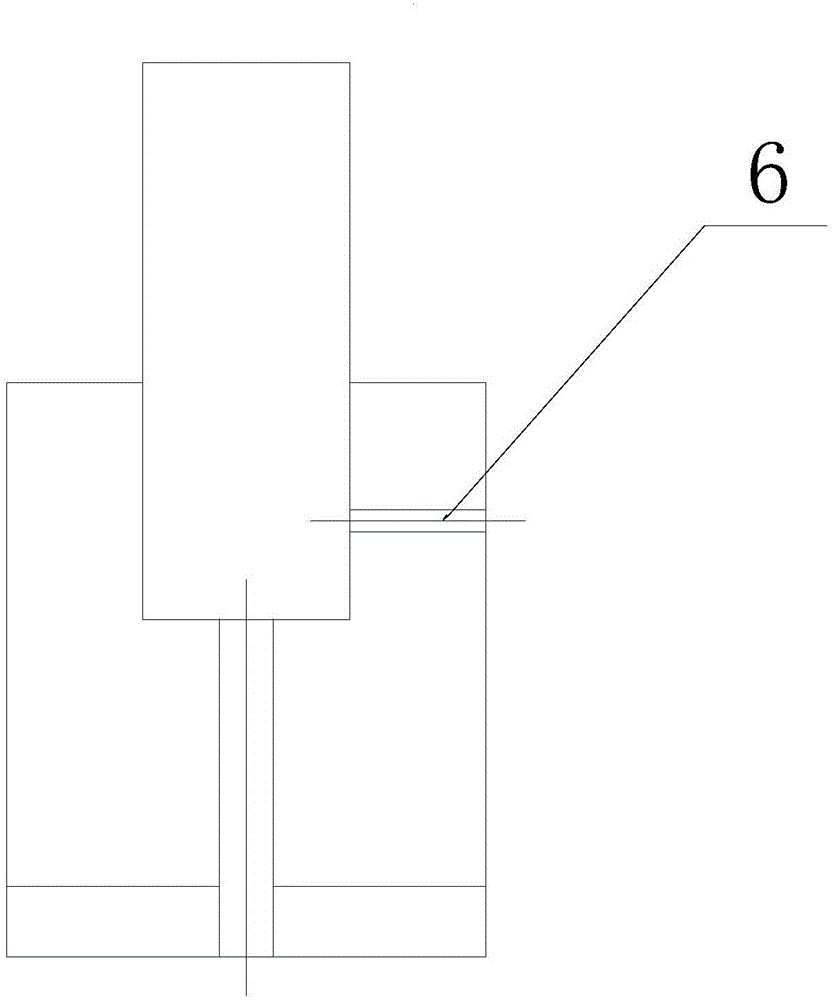

[0019] Such as figure 1 , figure 2 A kind of collective processing fixing seat shown is characterized in that: it comprises processing fixing seat 1 and fixing seat backing plate 2, and described processing fixing seat 1 is positioned at the top of fixing seat backing plate 2, and described processing fixing seat 1 and fixing seat pad The plate 2 is fixedly connected, and the processing fixing seat 1 is also provided with a screw hole 3, a workpiece hole 4, a top piece hole 5 and a side ejection pin hole 6, and the screw hole 3 is located at the four corners of the processing fixing seat 1, and the screws The hole and the pin hole are placed diagonally, the workpiece hole 4 is located on the processing fixture 1, the top piece hole 5 is located on the back of the workpiece hole 4, and the side ejector pin hole 6 is located on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com