Novel false proof bottle cap

An anti-counterfeiting bottle cap and a new type of technology are applied in the field of wine bottle caps, which can solve the problems affecting the appearance of the bottle cap, cannot be restored, and are damaged as a whole, achieve a good anti-counterfeiting effect, and change the effect of the realization method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

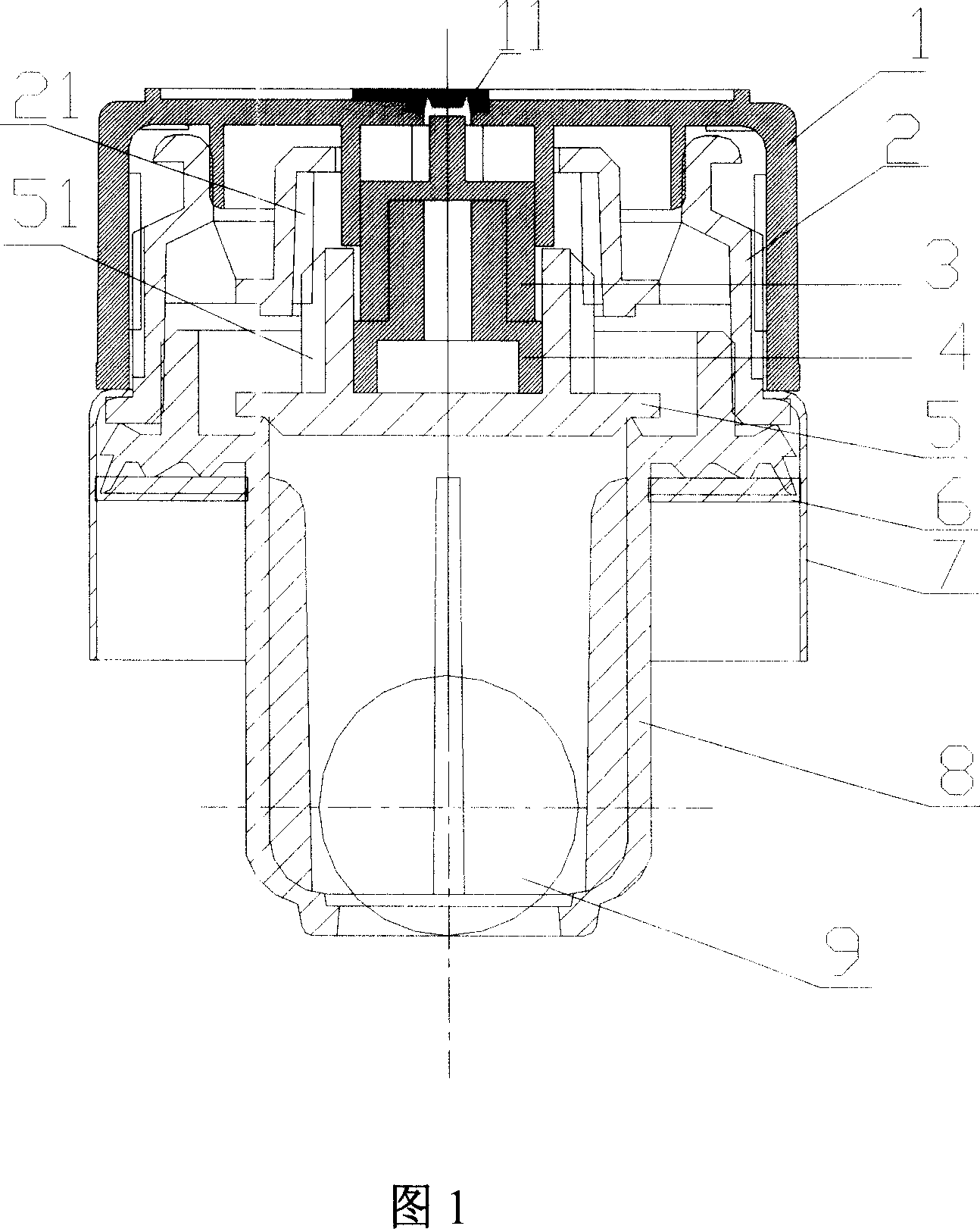

[0009] Referring to Figure 1, a new type of anti-counterfeit bottle cap, which includes an outer cover 1, an inner plug 8, a glass bead 9, a small valve 5, an aluminum ring 7 (a fixing ring of other materials with a fixing function can also be used), a gasket 6. Push out the nut 3, the connecting seat 2 and the anti-rotation screw 4, insert the inner plug 8 into the bottle mouth and lock the outer edge of the inner plug 8 and the bottle mouth through the aluminum ring 7, and the gasket 6 is located between the inner plug and the bottle mouth Between them, it can play a sealing role; the glass beads 9 are stuck on the lower mouth of the inner plug 8 to prevent backflow; On the upper part of the plug 8, the connecting seat 2 is fixed on the outer edge of the inner plug 8 through the aluminum ring 7, and there are anti-rotation ribs 21 on the inner side; the inner and outer sides of the small valve 5 also have anti-rotation ribs. 51 and the anti-rotation rib 21 on the inner side ...

Embodiment 2

[0014] The difference between this embodiment and Embodiment 1 is that in this embodiment, the lead between the ejection nut and the anti-rotation screw is smaller than the lead between the inner side of the outer edge of the outer cover and the outer edge of the connecting seat, and the ejection nut There is a connecting piece between the upper head and the corresponding upper cover part of the outer cover. The working principle and process of this embodiment are basically the same as that of Embodiment 1. The main reason is that Embodiment 1 utilizes that the lifting speed of the ejector screw is greater than that of the outer cover, thereby breaking the outer cover; this embodiment utilizes that the ejector screw rises The speed is less than that of the outer cover, so that the outer cover is pulled through the connector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com