Fixation carrier, production method of fixation carrier, use method of fixation carrier, and substrate reception container

A technology for fixing carriers and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as bad conditions, easy warping, and easy breakage, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

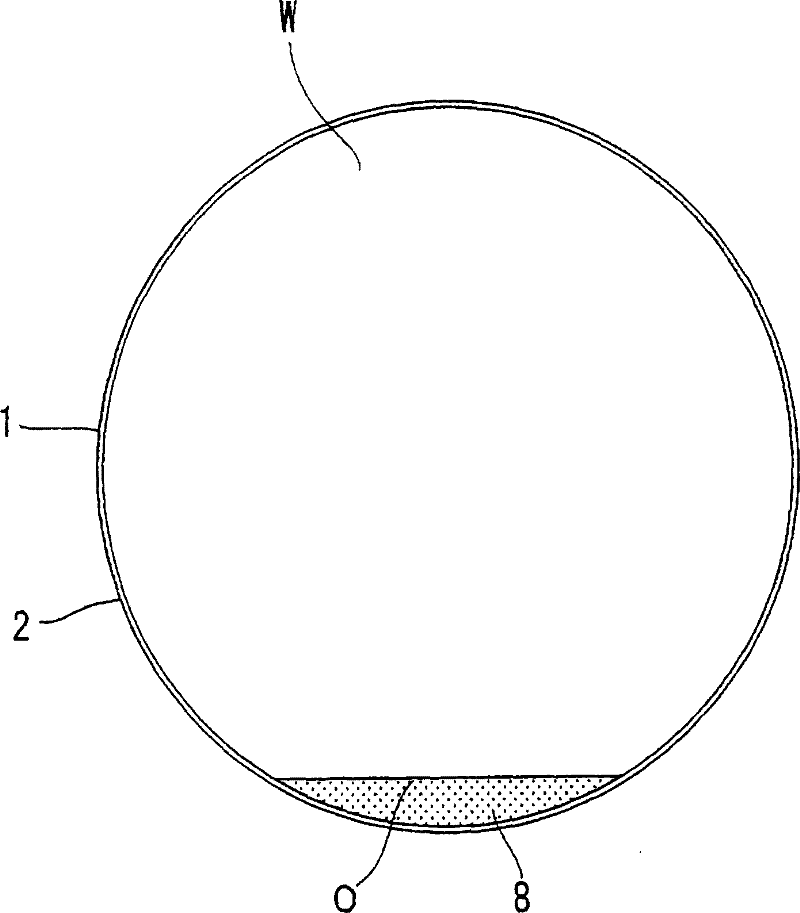

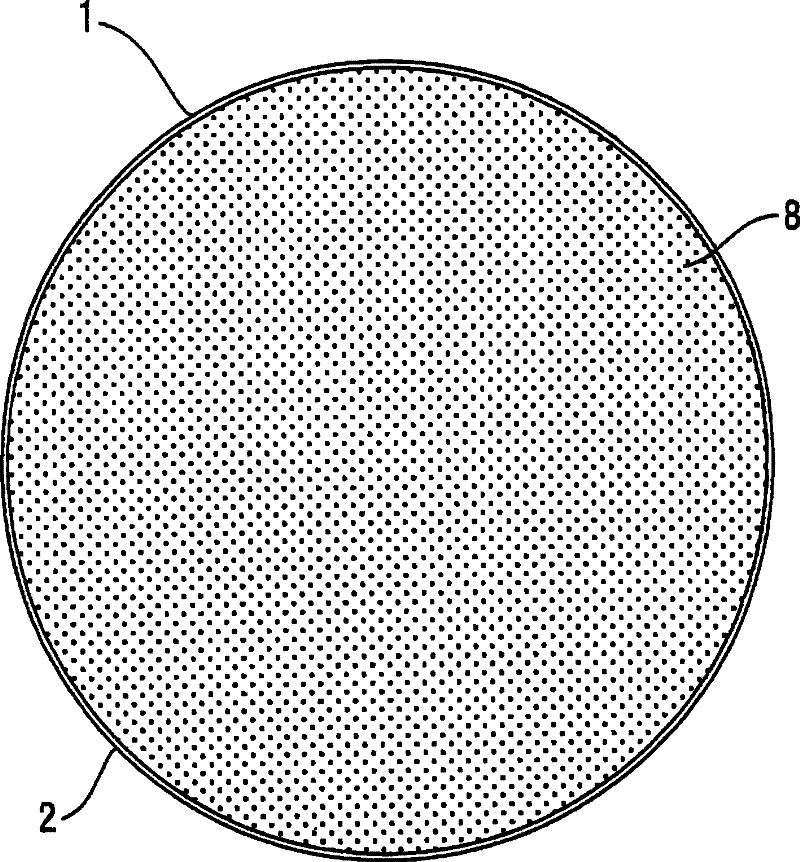

[0084] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings, and the fixed carrier 1 of the present embodiment is as follows: Figure 1 to Figure 15 As shown, it is equipped with a rigid base material 2 and an elastically deformable holding layer 8 covering the base material 2 to hold a semiconductor wafer W with a diameter of 300 mm (12 inches). container 20.

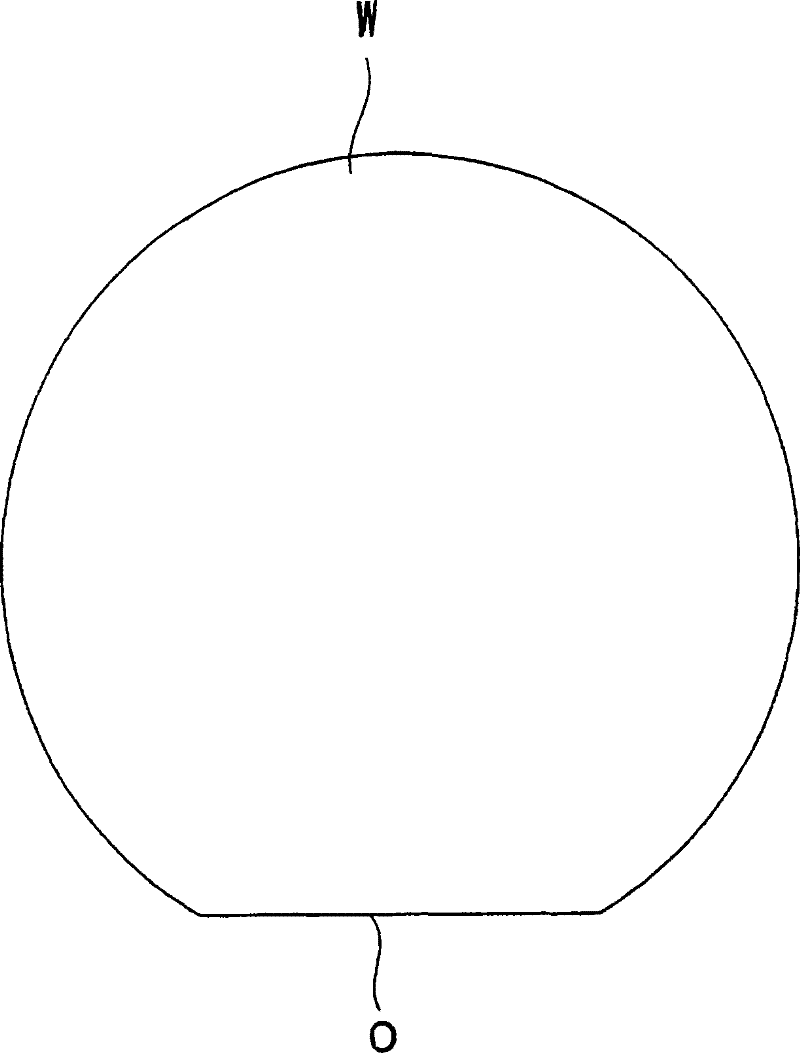

[0085] Semiconductor wafer W such as figure 1 and figure 2 As shown, it is basically composed of a round silicon wafer with a thickness of about 750 μm, and a linear orientation flat O (orientation flat) or a notch N is notched on the peripheral portion, and the orientation flat O or notch N is used to determine the crystal orientation and function for positioning. The semiconductor wafer W is bonded with a protective tape on the surface of the mirror surface on which the circuit is formed as a pattern, and the back surface is ground by a back gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com