Thermoplastic-imbibed diffusion media to help eliminate mea edge failure

A thermoplastic polymer, diffusion medium layer technology, used in fuel cell parts, solid electrolyte fuel cells, devices for coating liquids on surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

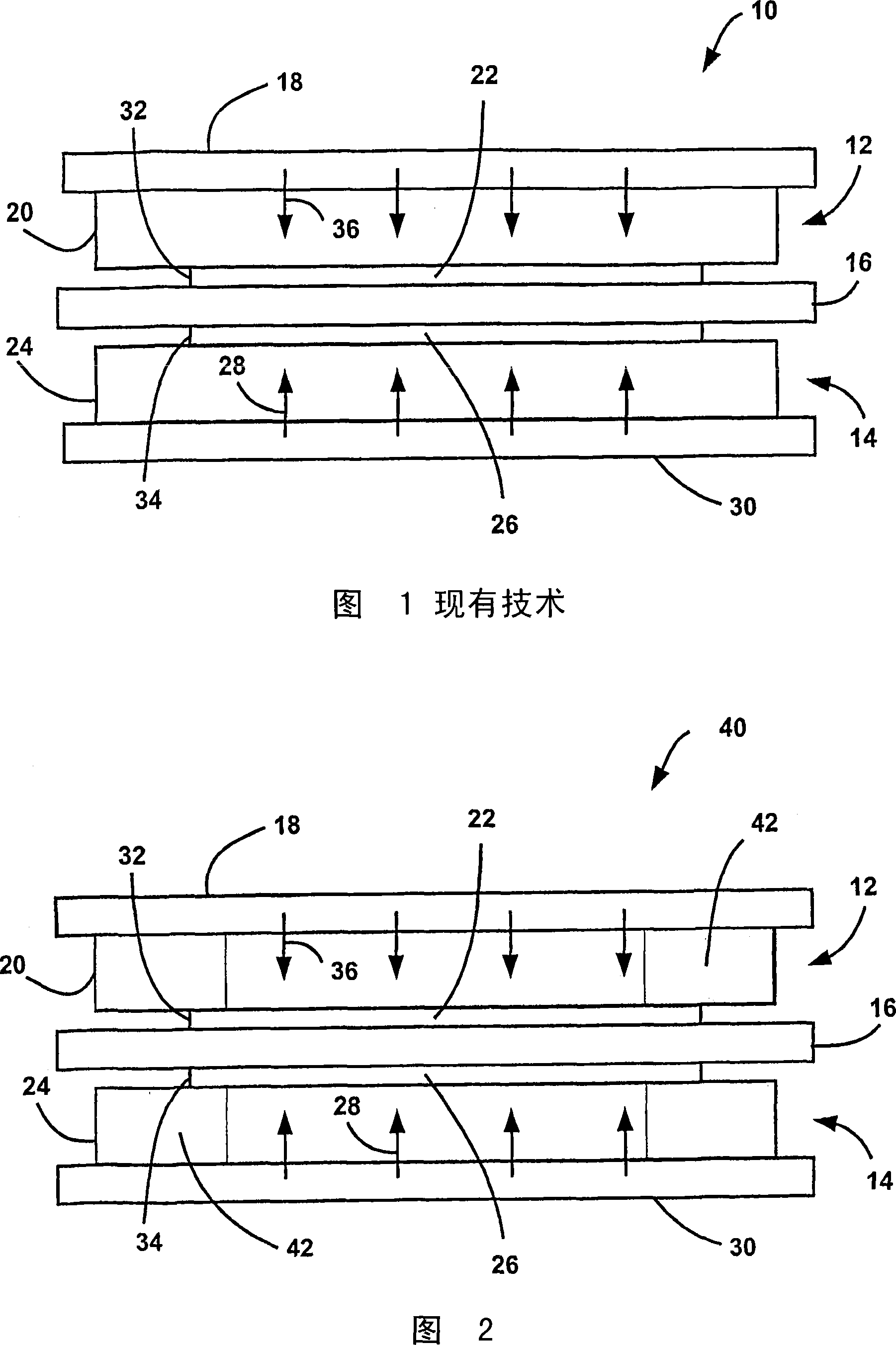

[0015] The following description of embodiments of the invention relating to fuel cells employing hydrogen and air barriers is merely exemplary in nature and is not intended to limit the invention or its application or uses.

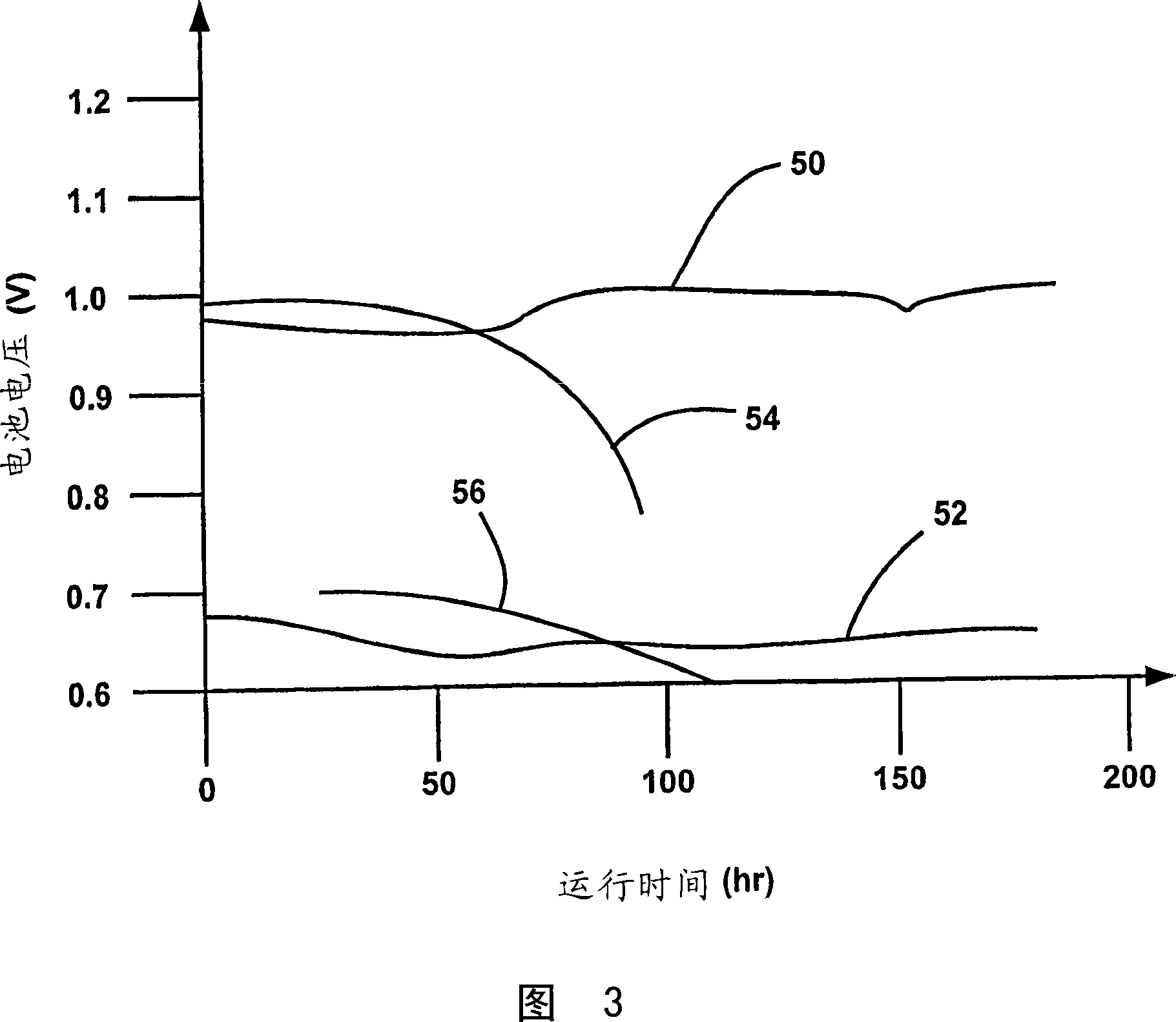

[0016] FIG. 2 is a cross-sectional view of a fuel cell 40 similar to fuel cell 10, wherein like reference numerals refer to like elements. According to one embodiment of the present invention, diffusion media layers 20 and 24 include a barrier 42 extending from the ends of diffusion media layers 20 and 24 to a suitable distance within edges 32 and 34 of catalyst layers 22 and 26, respectively. Barrier 42 may be any suitable material formed in diffusion media layers 20 and 24 to act as a barrier or impede propagation of either or both air flow 36 and hydrogen flow 28 outside catalyst layers 22 and 26 through membrane 16 . In other words, barrier 42 forces air flow 36 and hydrogen flow 28 into catalyst layers 22 and 26 , respectively, before entering membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com