Air outlet duct system

A technology for exhaust pipes and exhaust gas, which is applied to exhaust devices, mechanical equipment, engine components, etc., and can solve problems such as cooling water overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

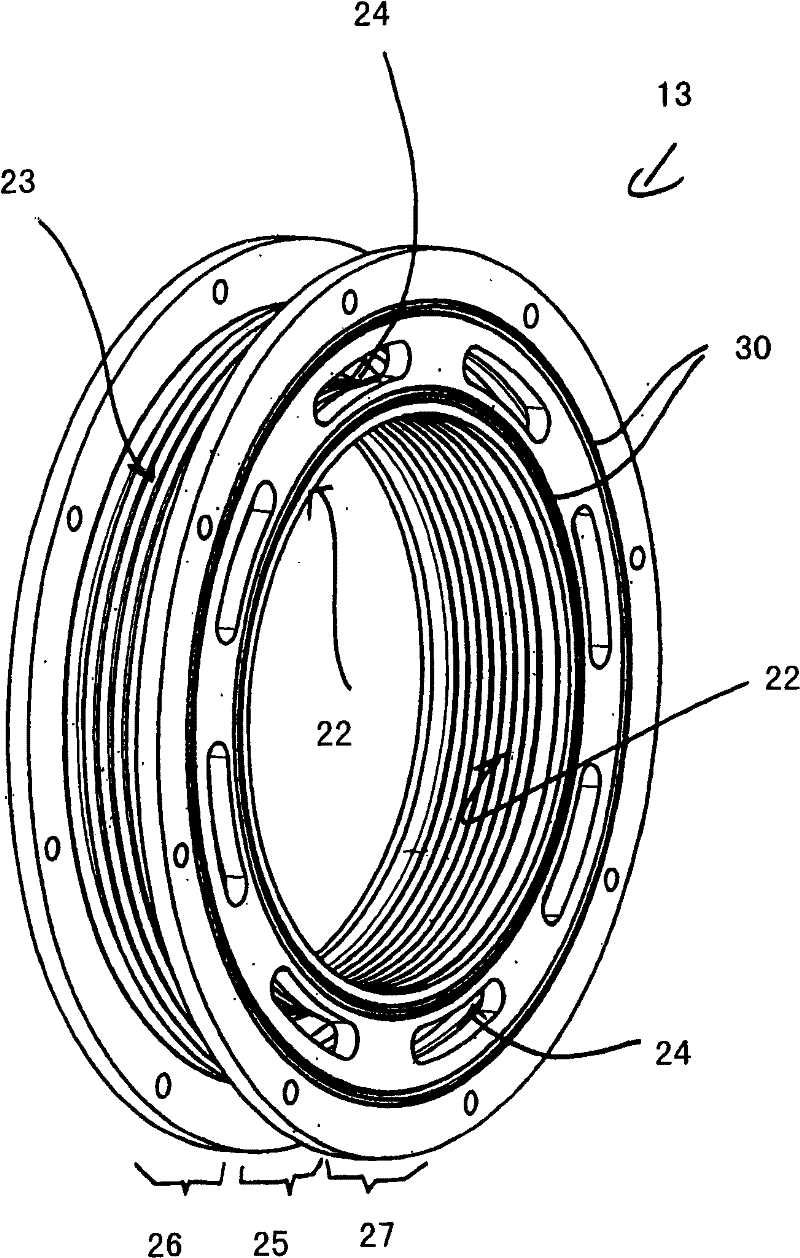

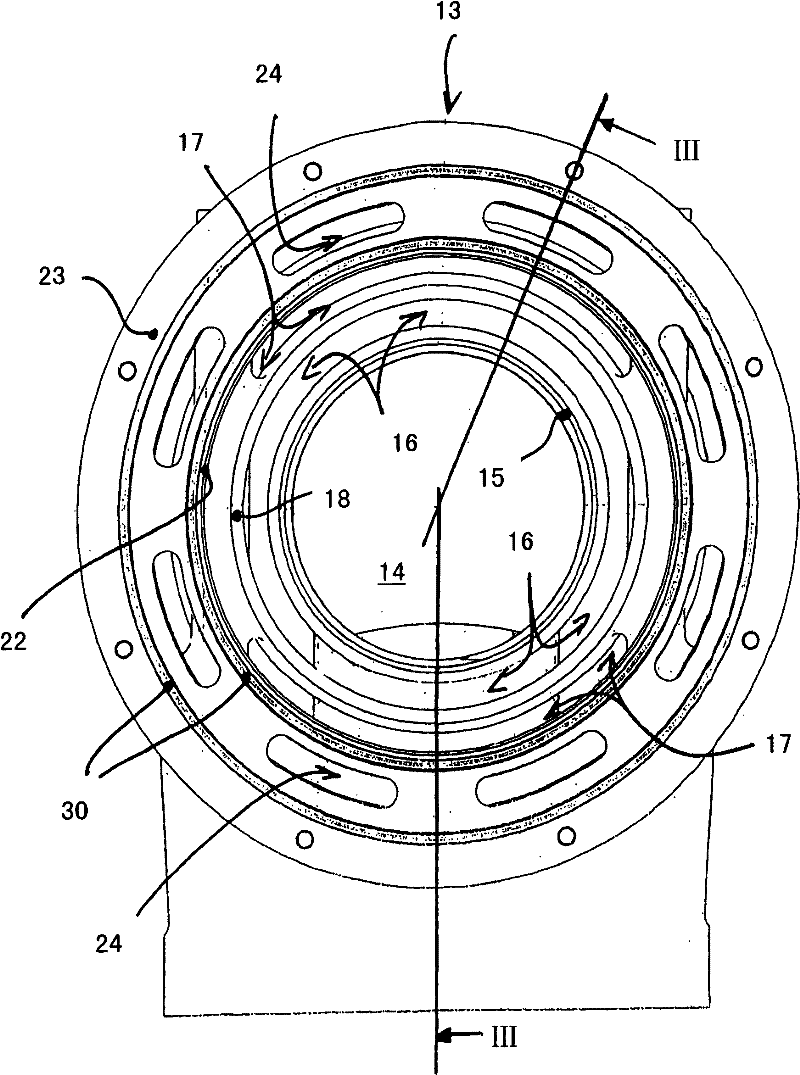

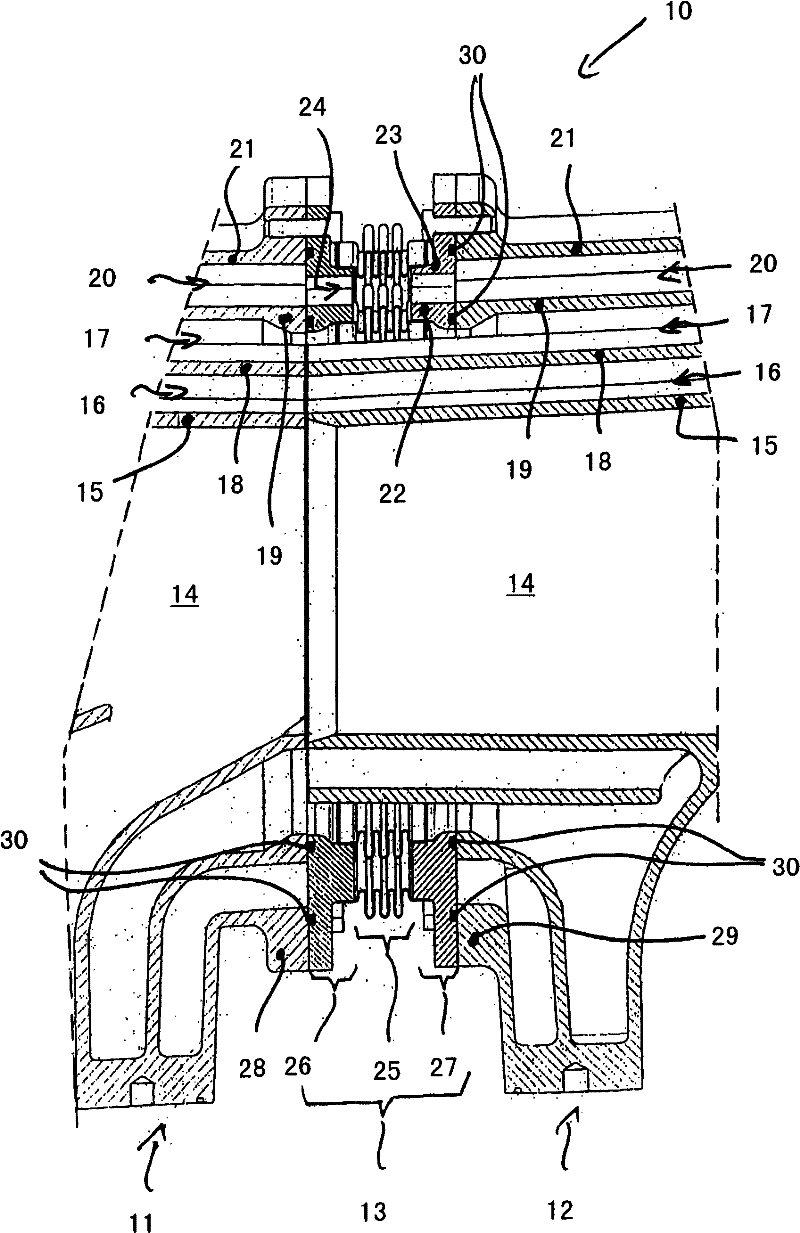

[0034] The invention relates to an exhaust pipe system for a multi-cylinder internal combustion engine, which is assembled from a plurality of exhaust pipe sections. Such an exhaust pipe system consisting of a plurality of exhaust pipe sections has basically been disclosed in DE 196 44 707 C2, and the invention here concerns such details of such an exhaust pipe system that even adjacent exhaust pipe Optimal connection between pipe sections. then image 3 The section shows the exhaust pipe system 10 according to the invention in the area of two adjacent exhaust pipe sections 11 , 12 which are closed using an exhaust gas compensator 13 interconnected. figure 1 A perspective overall view of such an exhaust gas compensator 13 is shown. figure 2 explained image 3 Section direction III-III of the section.

[0035] from image 3 As can be seen from FIG. 2 , each of the two exhaust pipe sections 11 and 12 includes an exhaust gas flow channel 14 which is defined by the tubula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com