Pretensioned prestressing box girder strain and relaxation process

A prestressing and pretensioning technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of poor synchronization, low work efficiency, and low safety, so as to achieve safe tensioning operations and improve the efficiency of tensioning , to avoid the effect of inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

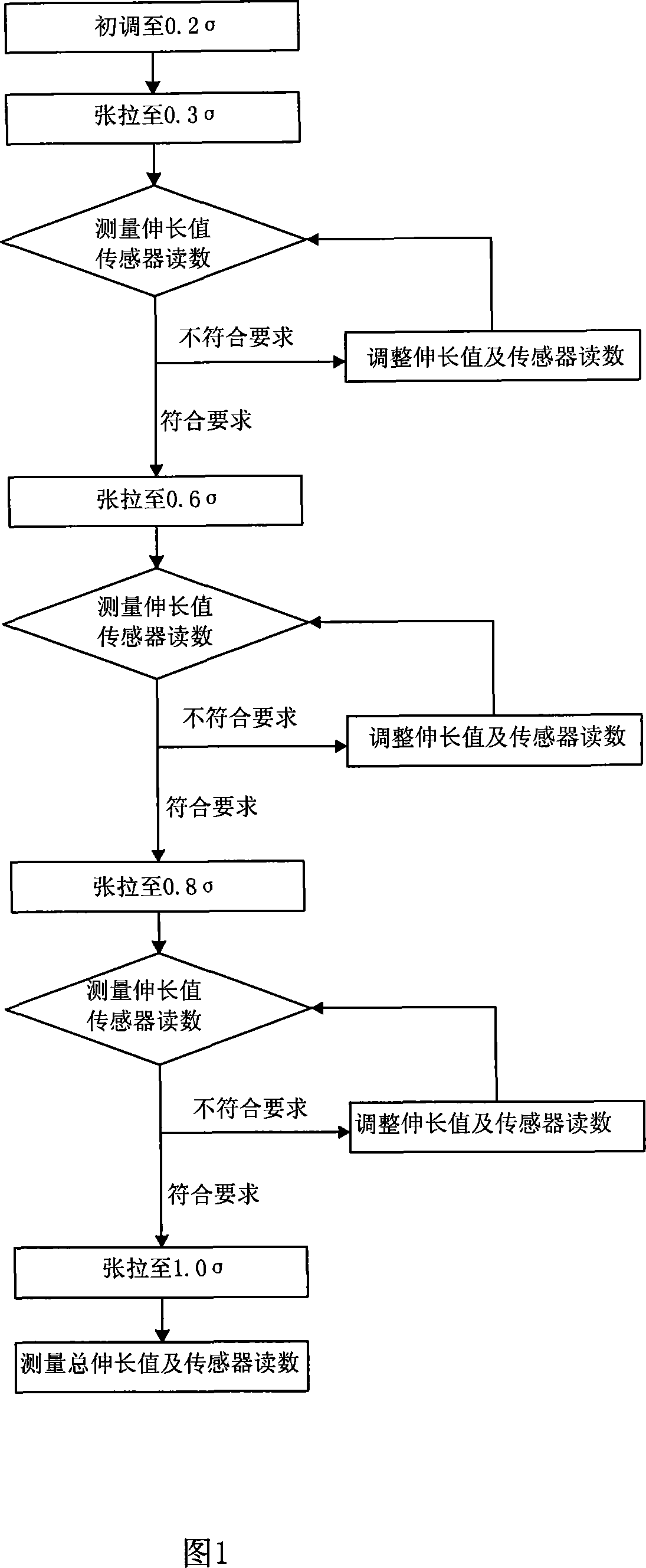

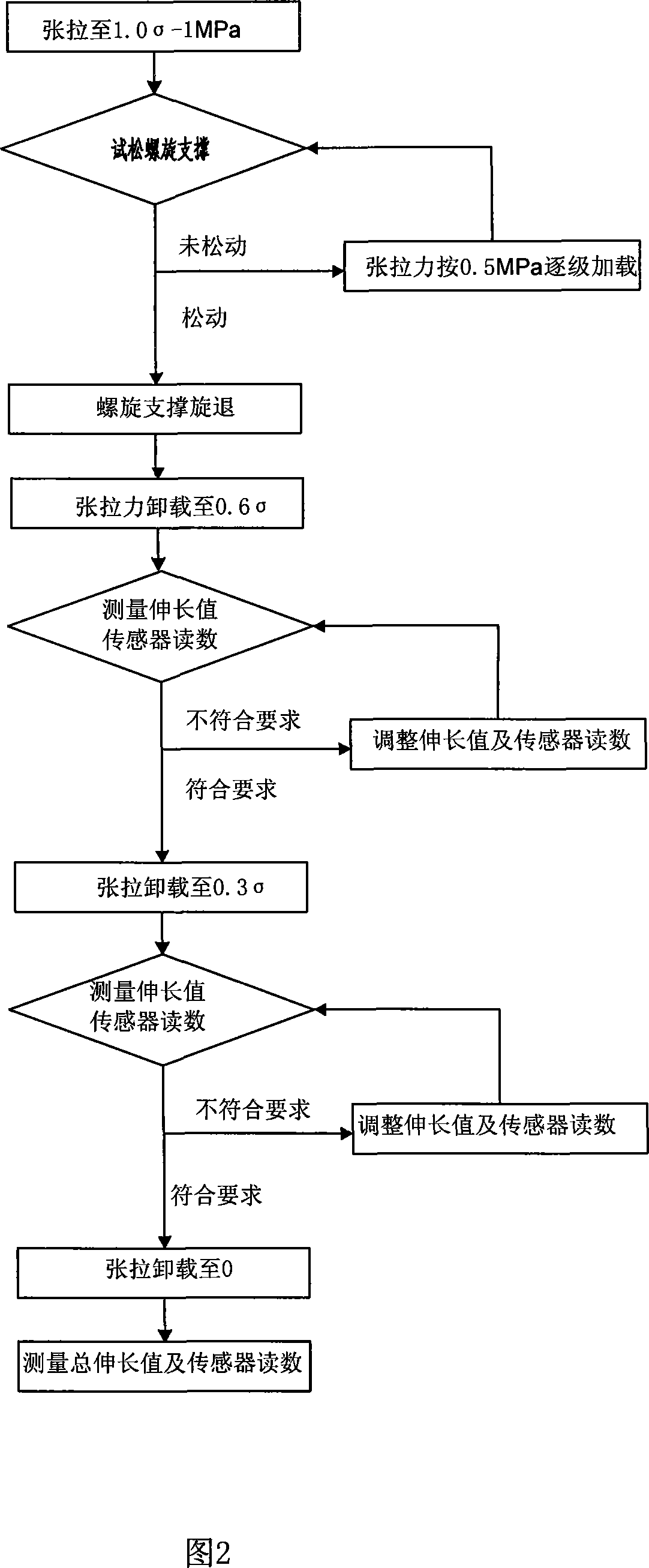

[0045] (1) Tension process:

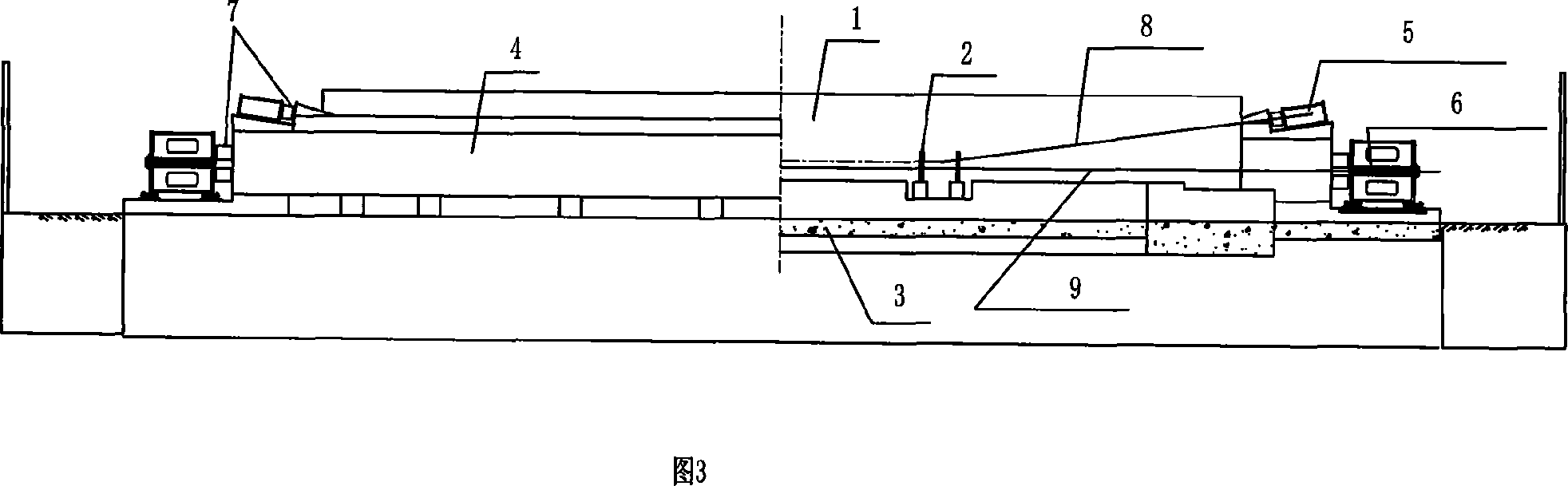

[0046] a. Install the formwork system and guide device of the box girder, and pass through the linear tendons. The straight ribs pass through the drawing holes opened at the corresponding positions of the end molds, and pass through the steel pipes set on the lower crossbeam. M18-1 single-hole clip tool is used for anchoring Anchored on the anchor pads of the lower beams at both ends of the beam body; through the bundle of broken line tendons, the broken line bars pass through the stretching holes on the end formwork, the guide rollers on the guide device in the middle of the beam body, and the steel pipes set on the upper beam, using M15 -1 The single-hole clip tool is anchored on the anchor plates of the upper beams at both ends; hydraulic jacks are respectively installed between the upper and lower beams and the ends of the beam body, and each hydraulic jack is connected to a hydraulic system;

[0047] b Adopt the synchronous hierarchical tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com