Digital camera lens

A digital camera and lens technology, applied in optics, instruments, optical components, etc., can solve the problems of not taking into account the processing errors of plastic lenses, the high precision requirements of aspheric lenses, and the degradation of image quality, etc., and achieve easy mass production. , the number of lenses is small, the effect of easy production and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

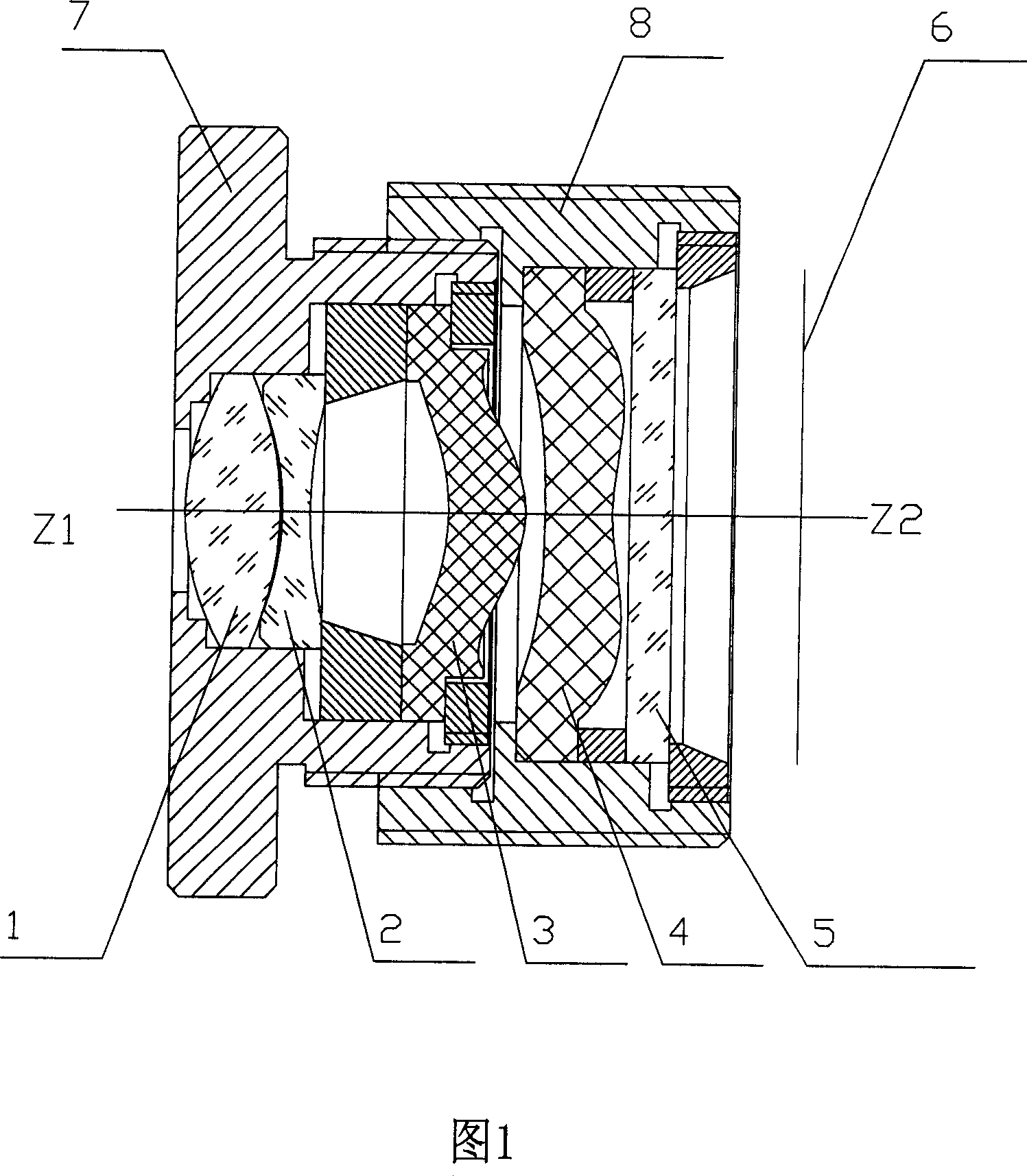

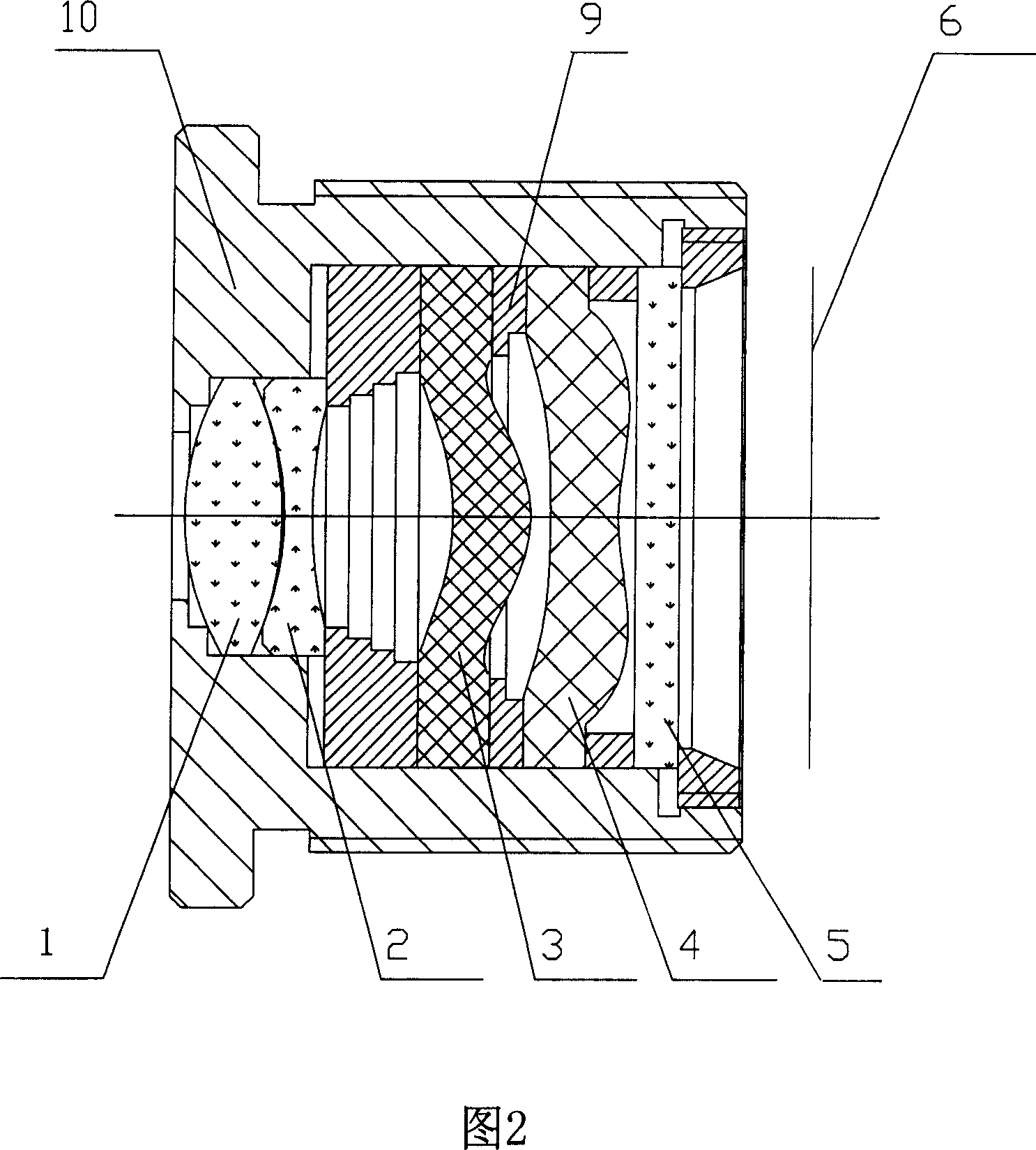

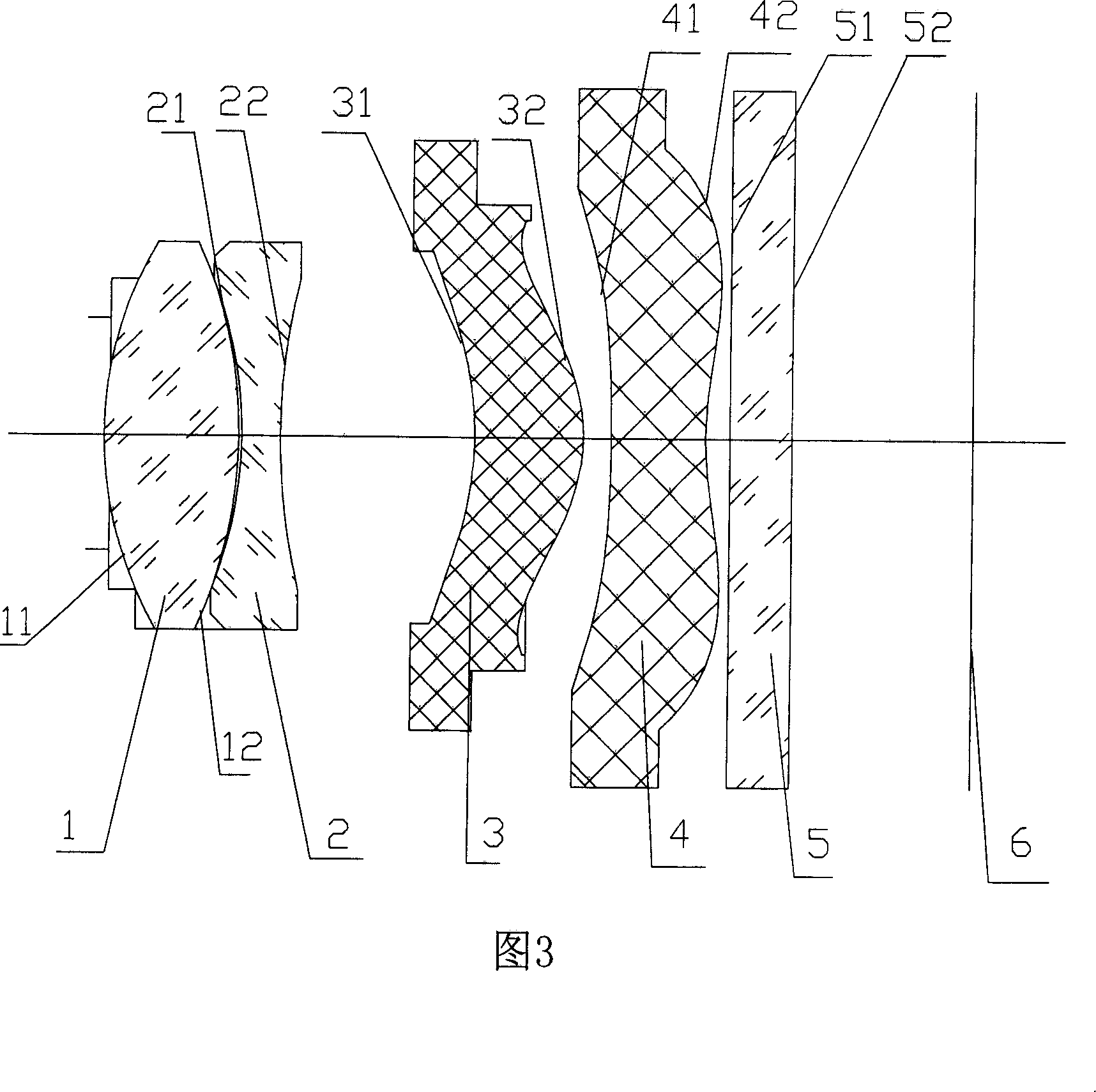

[0055] Referring to Fig. 1, digital camera lens of the present invention comprises first lens 1, second lens 2, third lens 3, fourth lens 4, plate glass 5 successively from object side, wherein Z1 represents object side, and Z2 represents image side , the digital camera lens also includes a diaphragm before the surface of the first lens 1, which acts to limit the total amount of light entering the lens, and also has a flat glass 5 on the side of the fourth lens near the image side, which acts on its surface An infrared cut-off filter film is coated on the top to cut off all infrared rays with a glass length of 645 mm or more. Of course, the infrared cut-off filter film can also be coated on the surface of the first lens; on the side of the flat glass 5 near the image square Z2 A cmos image sensor assembly is provided.

[0056] The first lens 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com