Combined type mould

A combined, mold technology, applied in the field of molds, can solve the problem of single coordination between the mold base and the mold core structure, and achieve the effects of convenient and fast maintenance, shortened manufacturing cycle, and reduced mold cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

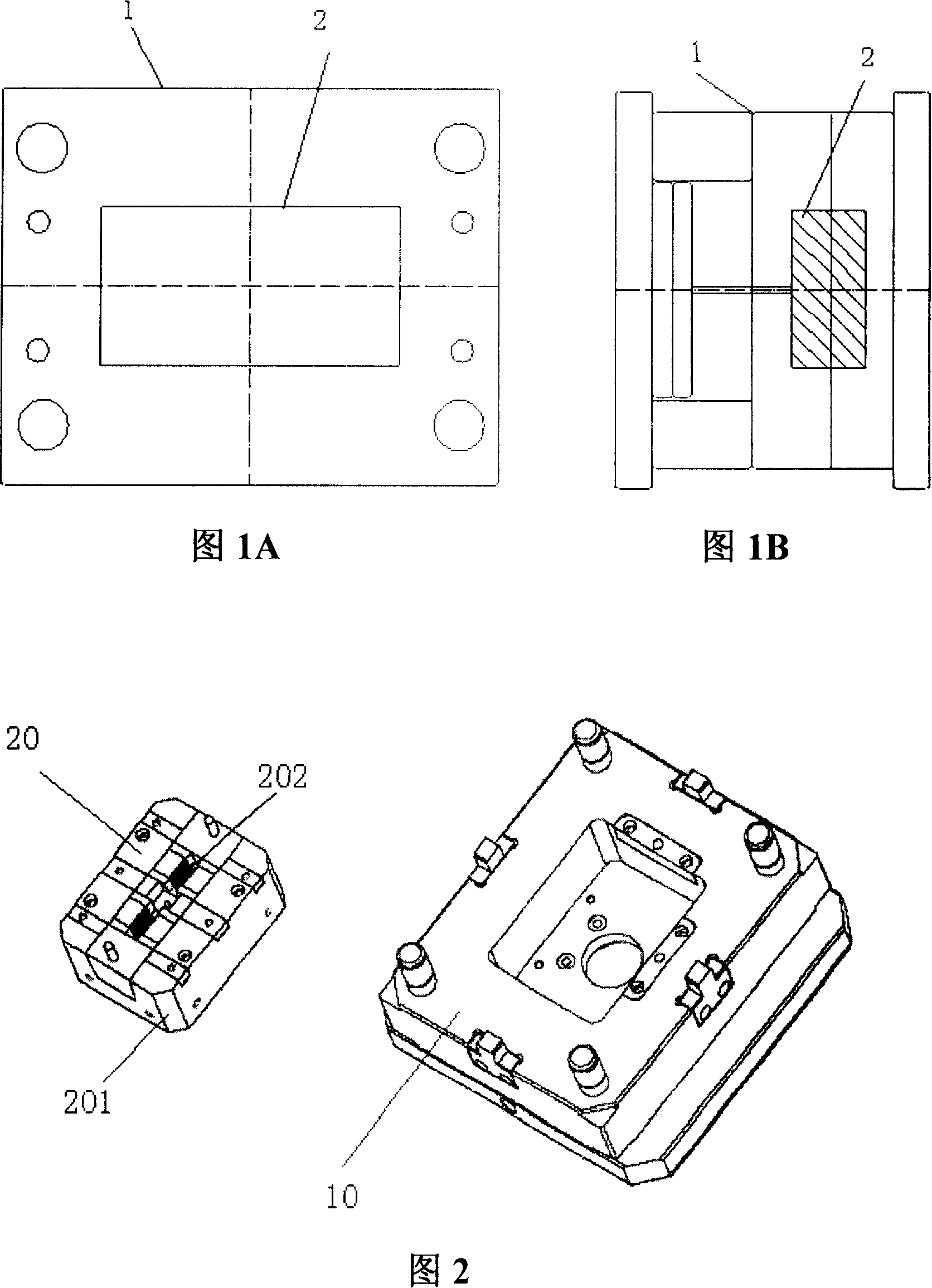

[0017] It can be seen from Figure 2 that the present invention includes: a common mold base 10, an interchangeable mold core 20; the interchangeable mold core 20 is detachably connected to the common mold base 10; the interchangeable mold core 20 may be One or more; the interchangeable mold core 20 includes a mold core frame 201 matched with the common mold frame 10 and a convertible insert 202 in the mold core frame 201;

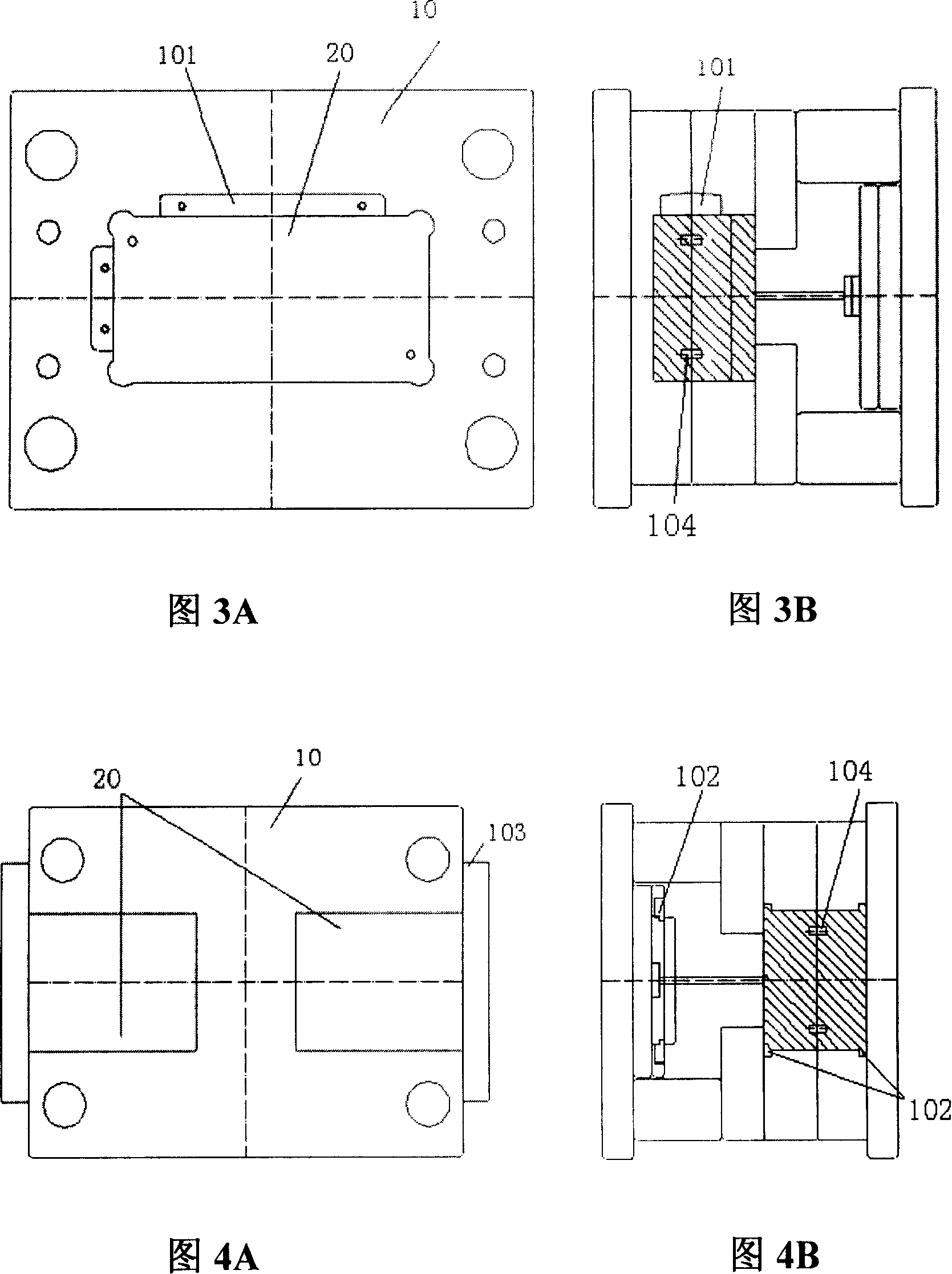

[0018] It can be seen from FIGS. 3A and 3B that the one interchangeable mold core is an O-shaped mold base clamped from the front; the mold core base 201 is diagonally connected to the common mold base 10 through the diagonal wedge 101;

[0019] It can be seen from Figures 4A and 4B that the two interchangeable mold cores are H-shaped mold bases clamped from the side; the mold core base 201 is positioned and connected to the common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com