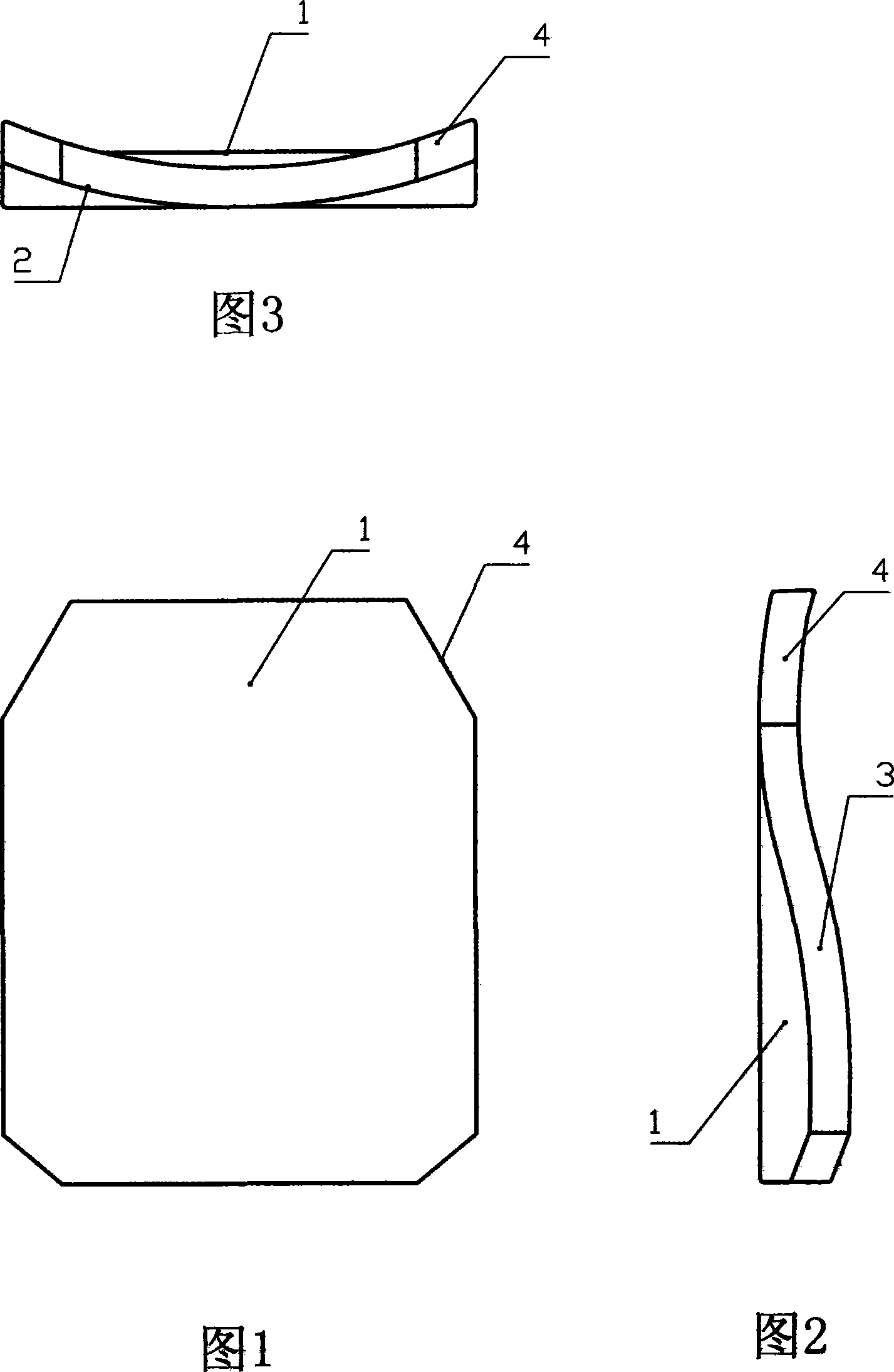

Multiple curved face polyethylene bulletproof chest-protector plate

A polyethylene, multi-curved technology, used in protective equipment, defenses, personnel protection equipment, etc., can solve the problems of complicated manufacturing process, poor ballistic resistance, uncomfortable wearing, etc., and achieve simple process, good ballistic resistance, Comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: 130 layers of high-strength and high-modulus polyethylene non-woven fabrics were hot-compressed and laminated to obtain a product with a thickness of 10 mm and a weight of 1.1 kg. After testing, it can resist the 51-B (7.62mm) steel core bullet fired by the 79-type submachine gun with a bullet speed of 500m / s, and meets the level 5 standard of GA141-2001.

Embodiment 2

[0013] Example 2: 270 layers of high-strength and high-modulus polyethylene non-woven fabrics were hot-compressed and laminated to obtain a product with a thickness of 20 mm and a weight of 1.5 kg. After testing, it can resist the M80 bullet (7.62mm 51-B steel core bullet) with a bullet velocity of 855m / s, and meets the NiJ0101.04III level standard formulated by the American Institute of Justice.

Embodiment 3

[0014] Embodiment 3: each 50 pieces of single-sided polyethylene bulletproof breastplates and chamfered multi-curved polyethylene bulletproof breastplates are tried on by 100 experimenters at the same time, and the statistical results show that the multi-curved polyethylene bulletproof breastplates are tried on. 50 people feel comfortable to wear and reflect well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com