Engine fastener of a mounting system interposed between an attachment strut and an aircraft engine

An aero-engine and assembly system technology, applied in the layout/installation of power plants, aircraft parts, power plant construction, etc., can solve the difficulty of force transmission, unoptimized total weight and size of the main body, unfavorable overall size and weight, etc. problem, to achieve the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

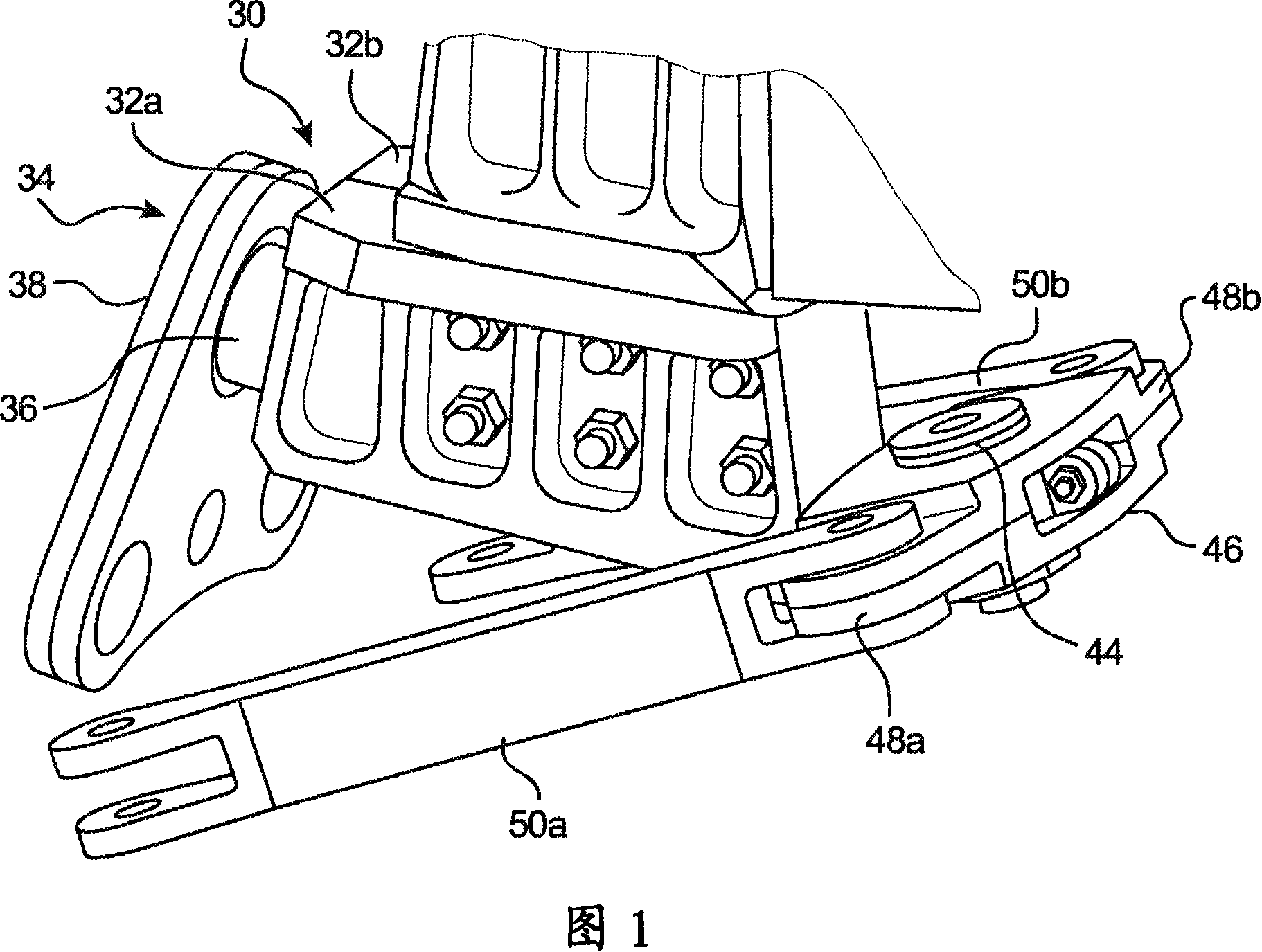

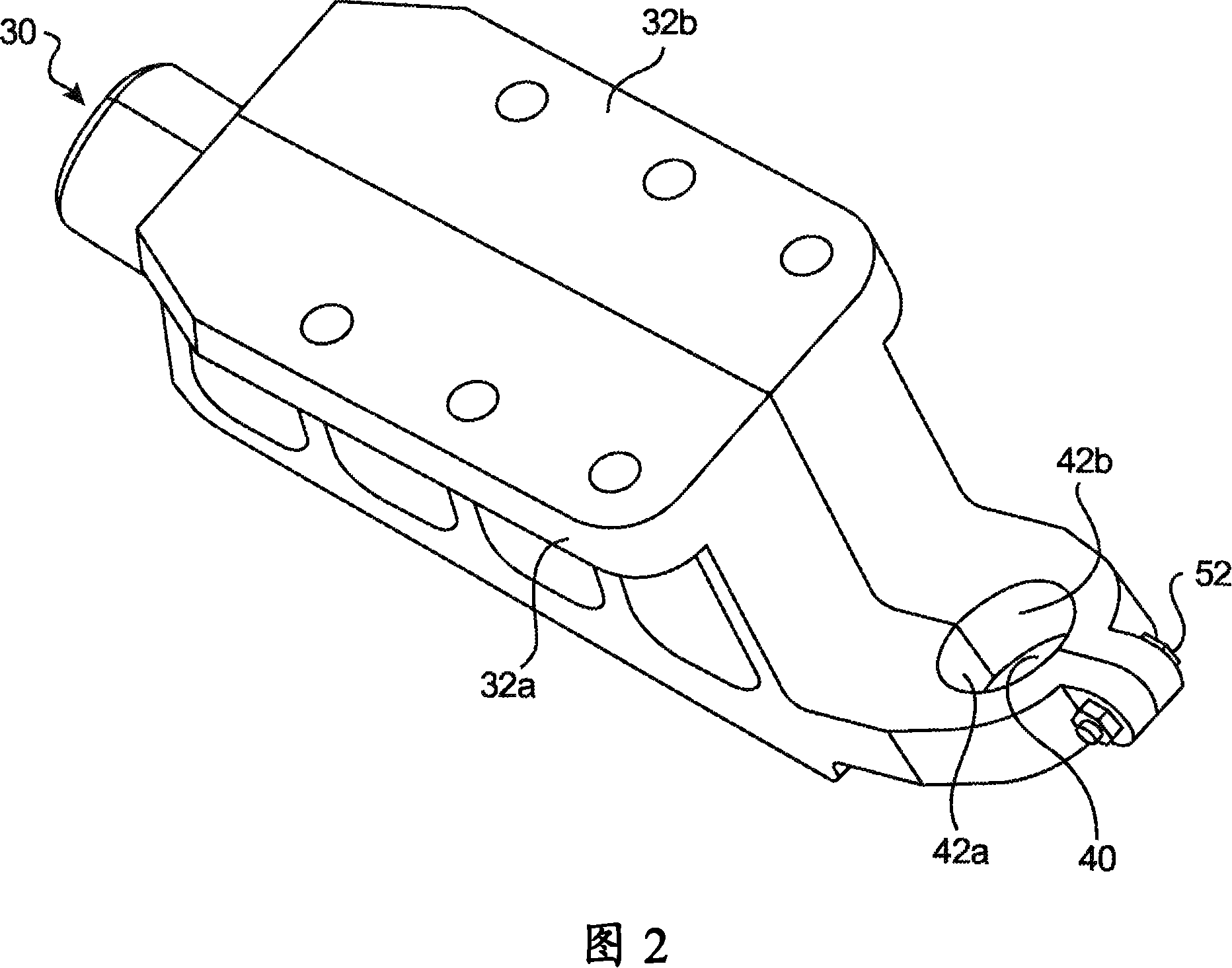

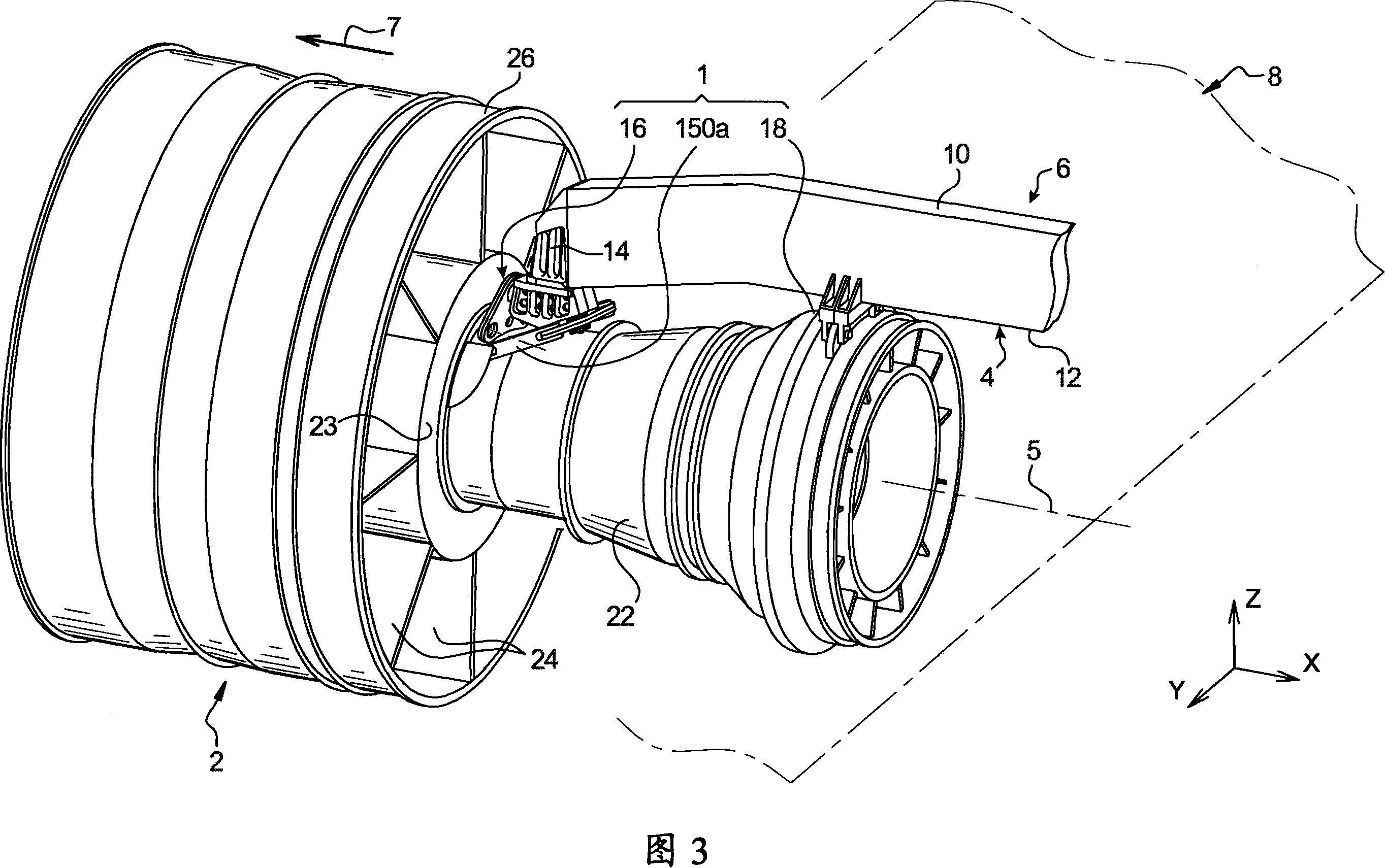

[0040] Referring first to FIG. 3 , there is shown an assembly system 1 in a preferred embodiment of the present invention, wherein the assembly system 1 is installed between an aeroengine 2 and a rigid structure 4 of an accessory strut 6 fixed under the wing of the aircraft, for For reasons of clarity of simplification, the aircraft wing is shown only diagrammatically and generally designated by the reference numeral 8 . It should be noted that the mounting system 1 is suitable for use in combination with a turbojet engine 2 , but, of course, can be designed as a system for suspending any other type of engine, such as a turboprop, within the scope of protection of the invention. Moreover, the application of the assembly system 1 is not limited to the example shown in FIG. 3 , in which the engine 2 is designed to be suspended under the wing 8 of an aircraft.

[0041]Throughout the following description, by convention, the longitudinal direction parallel to the longitudinal axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com