An Anti-Thinning, Wide Welding Width, Permanent Enhanced Friction Stir Welding Method

A technology of friction stir welding and friction stir, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of thinning of the base metal in the welding zone, adhesion tools, rough surface forming, etc., and achieve improved corrosion resistance properties, improving weldability, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

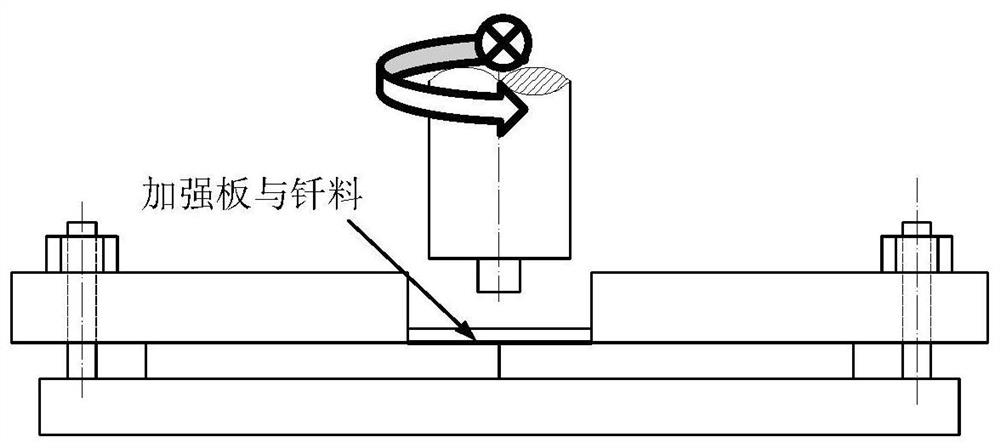

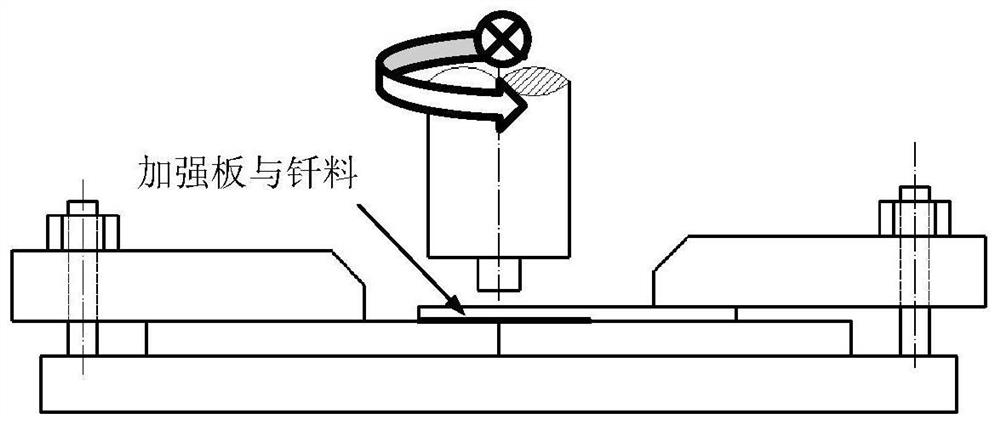

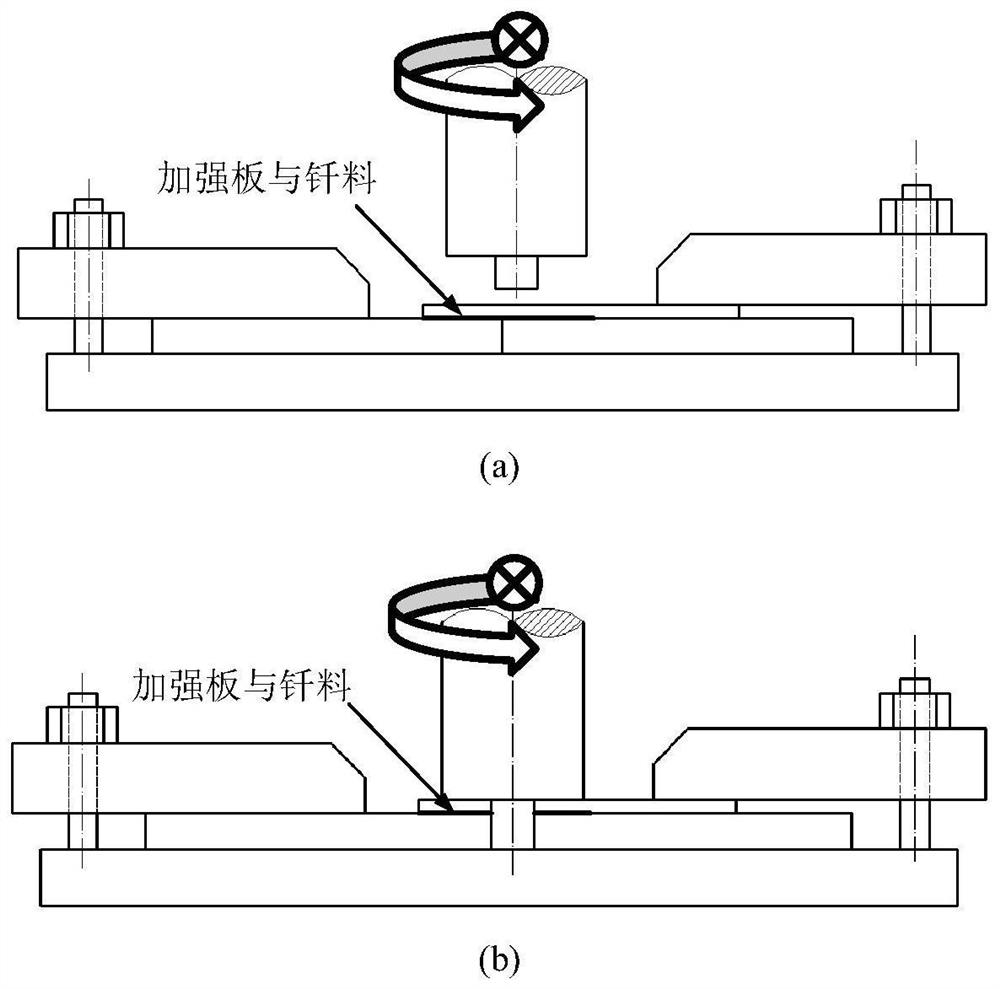

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0053] In the present invention, the applicant proposes that there are two "inherent" problems of thinning of the same metal welding in FSW and roughness of the welding surface of dissimilar metals, which can be solved by adding the same (or different) components on the surface of the two base metals. ), plates with excellent high temperature plasticity and low temperature plasticity (which can be called reinforcement plates, cover plates, cladding plates or surfacing plates, collectively referred to as reinforcement plates) can be solved. The key point to determine the success of this idea is how to ensure firm, convenient and flexible lap welding between the reinforcement plate and the base metal surface. Based on the previous research accumulation of the research group, the applicant proposed a method to prevent thinning and improve the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com