Welding tool achieving weld joint zero thinning during friction stir welding and welding method

A technology of friction stir welding and welding methods, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of high cost, low efficiency, narrow applicable range, etc., and achieve low processing and manufacturing costs, wide application range, Guarantee the effect of high-quality forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

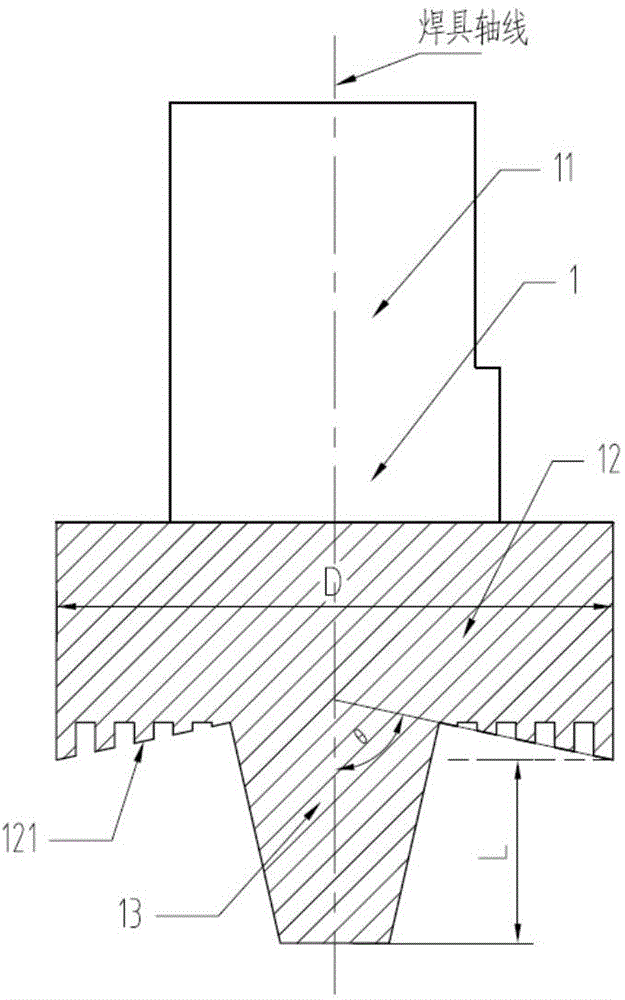

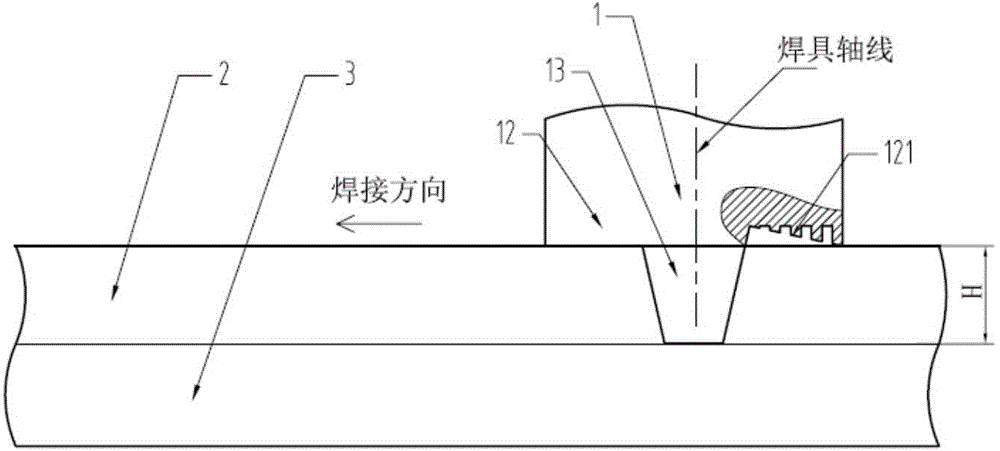

[0037] In the welding tool of this embodiment, the clamping body, the shaft shoulder and the stirring pin are integrated from top to bottom. The included angle between the end surface of the shoulder and the axis of the welding tool is 78°, and a spiral groove structure is processed on the end surface of the shoulder. The diameter of the shoulder is 24mm, and the length of the stirring pin is 5.85mm. The 5.94mm thick aluminum alloy plate is used as the welding object. During welding, the rotation speed of the welding tool is 800r / min, the welding speed is 100mm / min, the indentation of the shoulder of the welding tool to the upper surface of the base metal to be welded is 0mm, and the inclination angle of the welding tool is 0°.

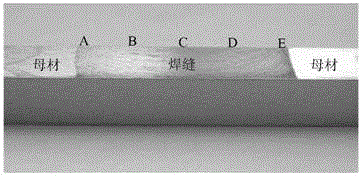

[0038] Cut along the vertical welding direction after welding image 3 As shown in the analysis sample, by image 3 It can be seen that the weld seam is well formed and no flash appears. Using a spiral micrometer, the image 3The weld seam thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com