Pressing switch

A technology of switches and openings, applied in the direction of electric switches, electrical components, emergency actuators, etc., can solve the problems of thinning and thickening of the push switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

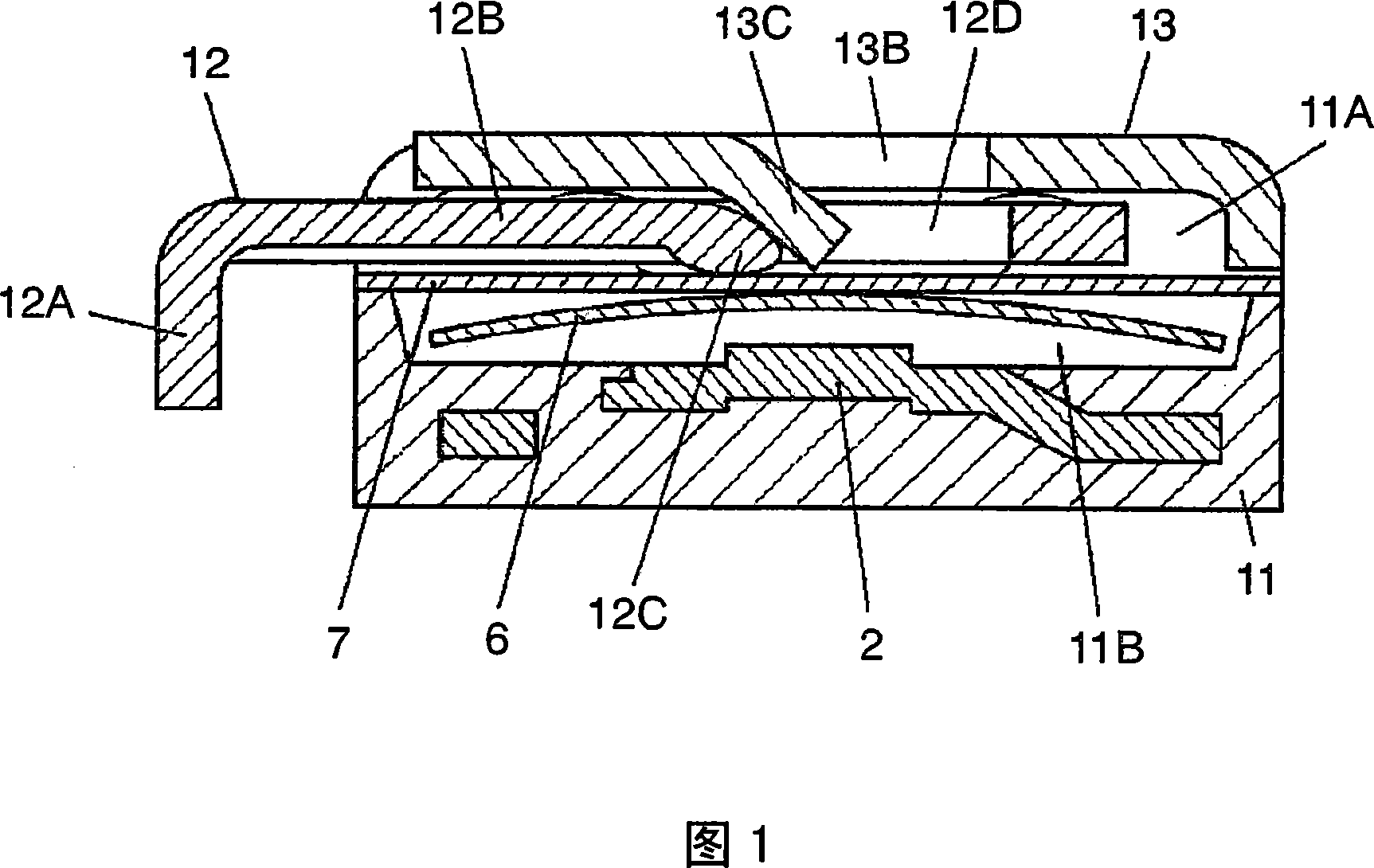

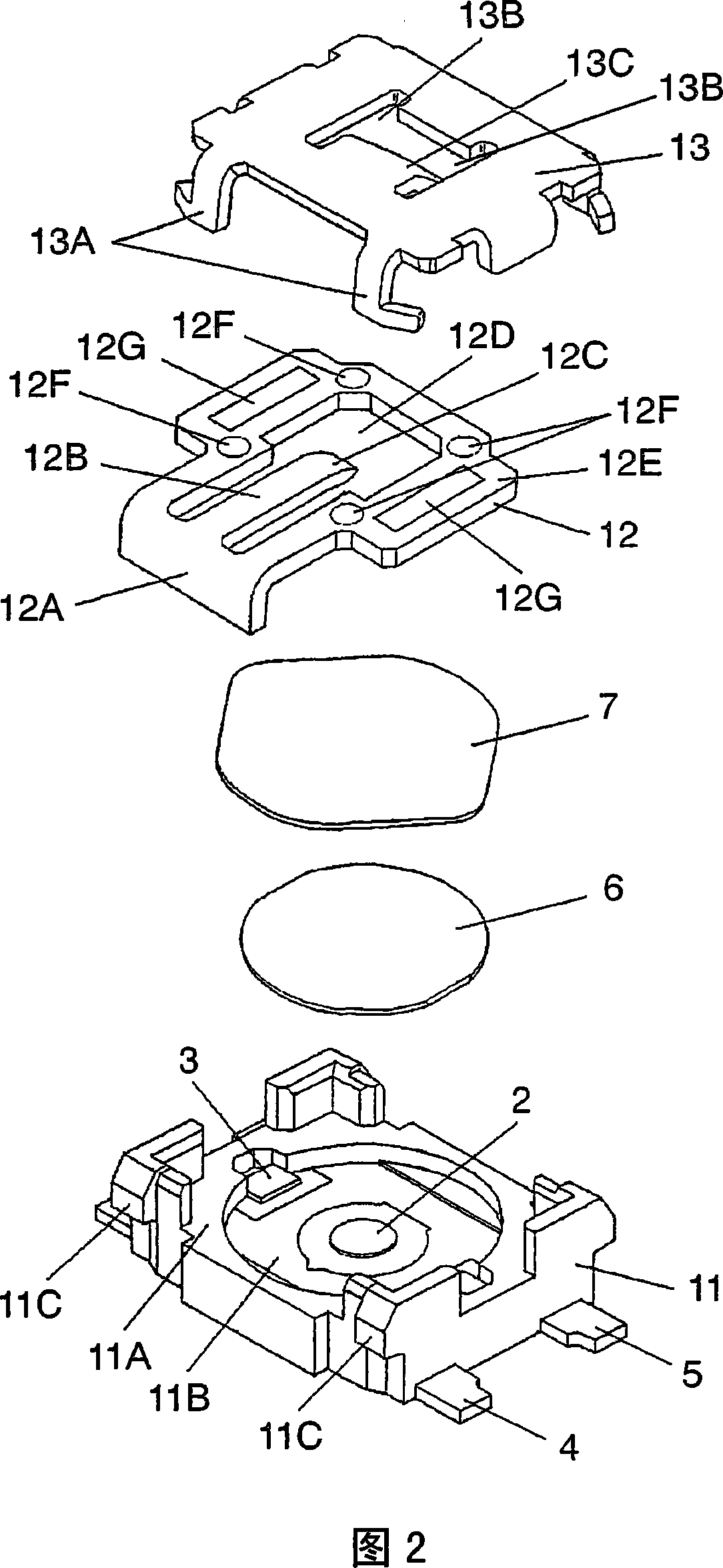

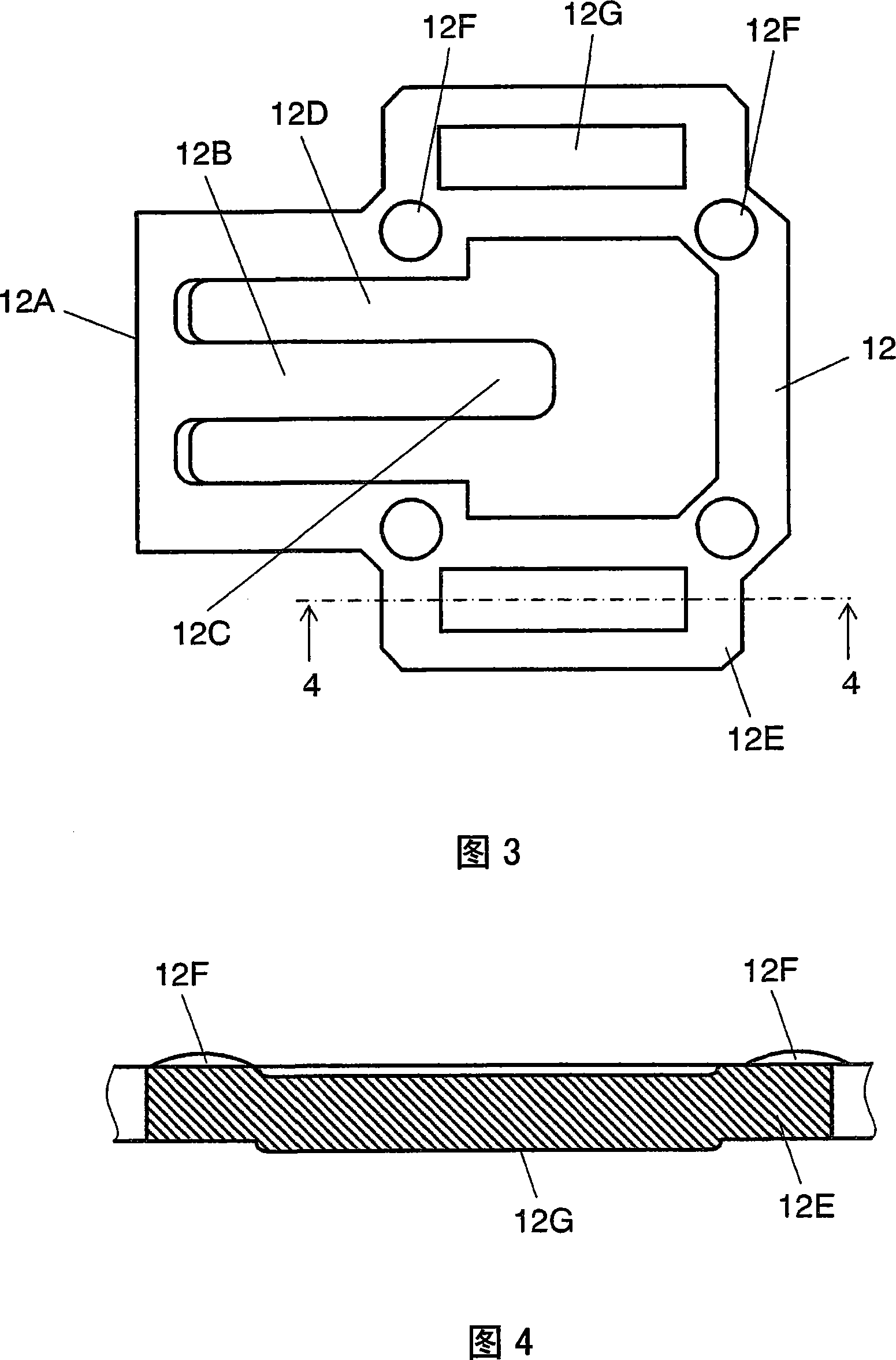

[0034] FIG. 1 is a sectional view of a push switch according to an embodiment of the present invention, and FIG. 2 is an exploded perspective view of the push switch. FIG. 3 is a plan view of the operating body of the push switch, and FIG. 4 is a cross-sectional view taken along line 4-4 in FIG. 3 . In addition, FIG. 5 is a cross-sectional view showing the operating state of the push switch, and FIG. 6 is an external view of an operating body in another embodiment.

[0035] As shown in FIGS. 1 and 2 , the push switch according to this embodiment has a switch case 11 made of a square insulating resin having a substantially circular recess 11B recessed from the bottom surface of an upper opening 11A. constitute. Furthermore, on the inner bottom surface of the recessed portion 11B, the central fixed contact 2 and a pair of outer fixed contacts 3 at an equal distance across the central fixed contact 2 are exposed. In addition, terminals 4 and 5 respectively connected to the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com