Railway ground crosstie

A technology for railway sleepers and sleepers, which is applied in the field of improved railway foundation sleepers, and can solve the problems of reducing the volume of sleepers without providing them, saving materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

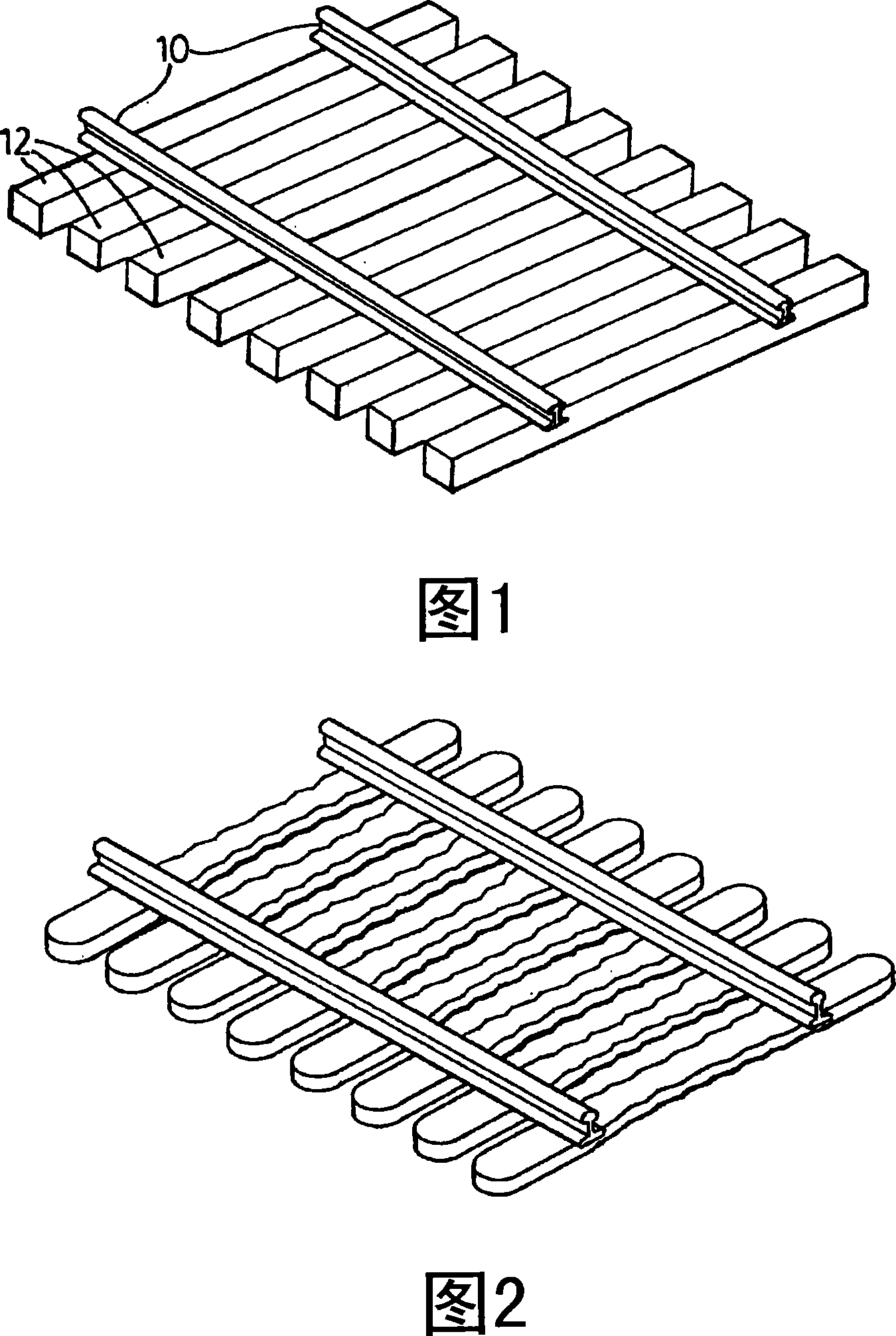

[0060] Referring to Figures 1 and 3 there is shown a steel rail 10 fixed vertically to a plurality of parallel timber ties 12 embedded in a ballast bed 14 according to the prior art.

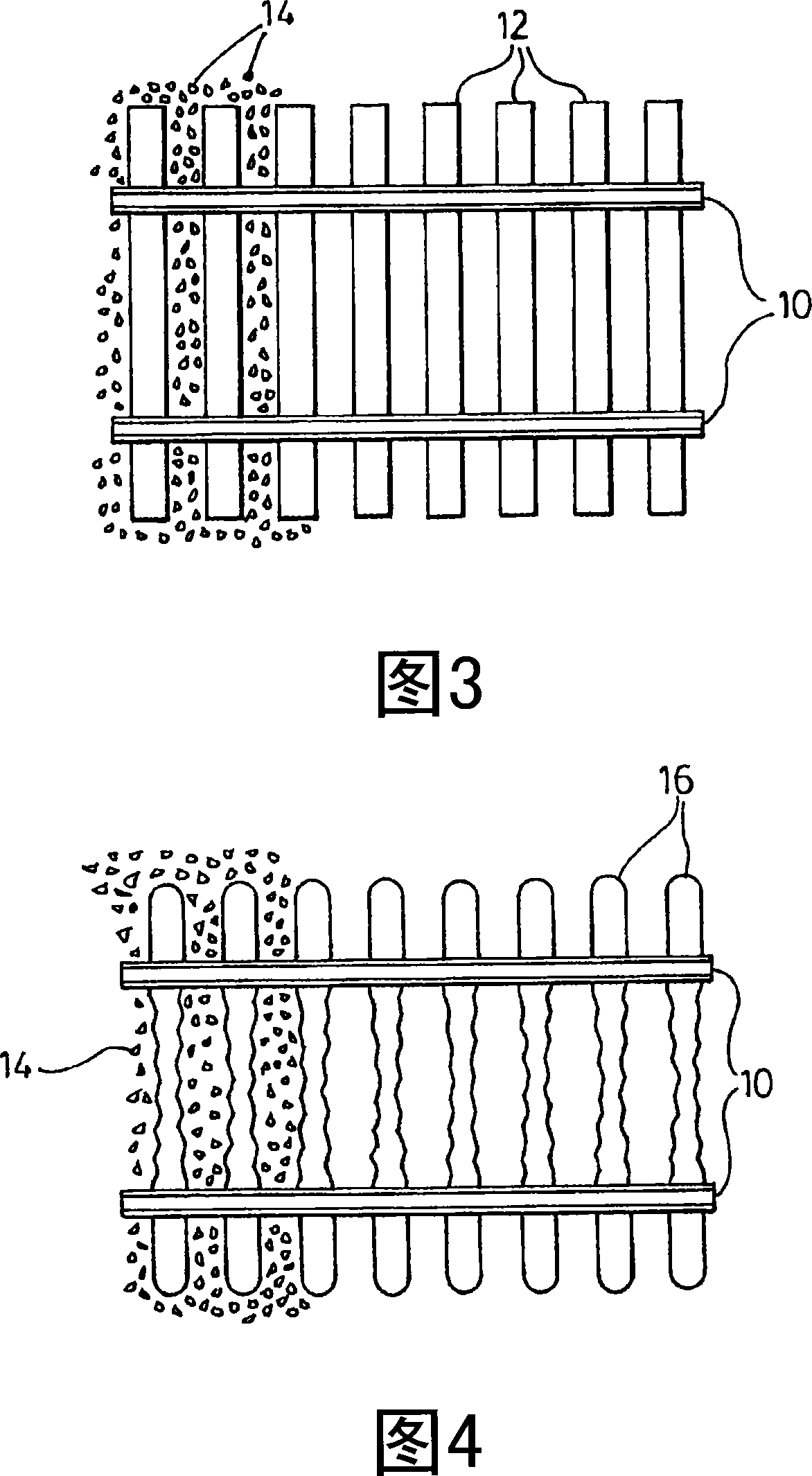

[0061] 2 and 4 illustrate a steel rail 10 secured to a plurality of lignocellulosic-resin (phenol formaldehyde) composite sleepers 16 embedded in a ballast bed 14 according to the present invention.

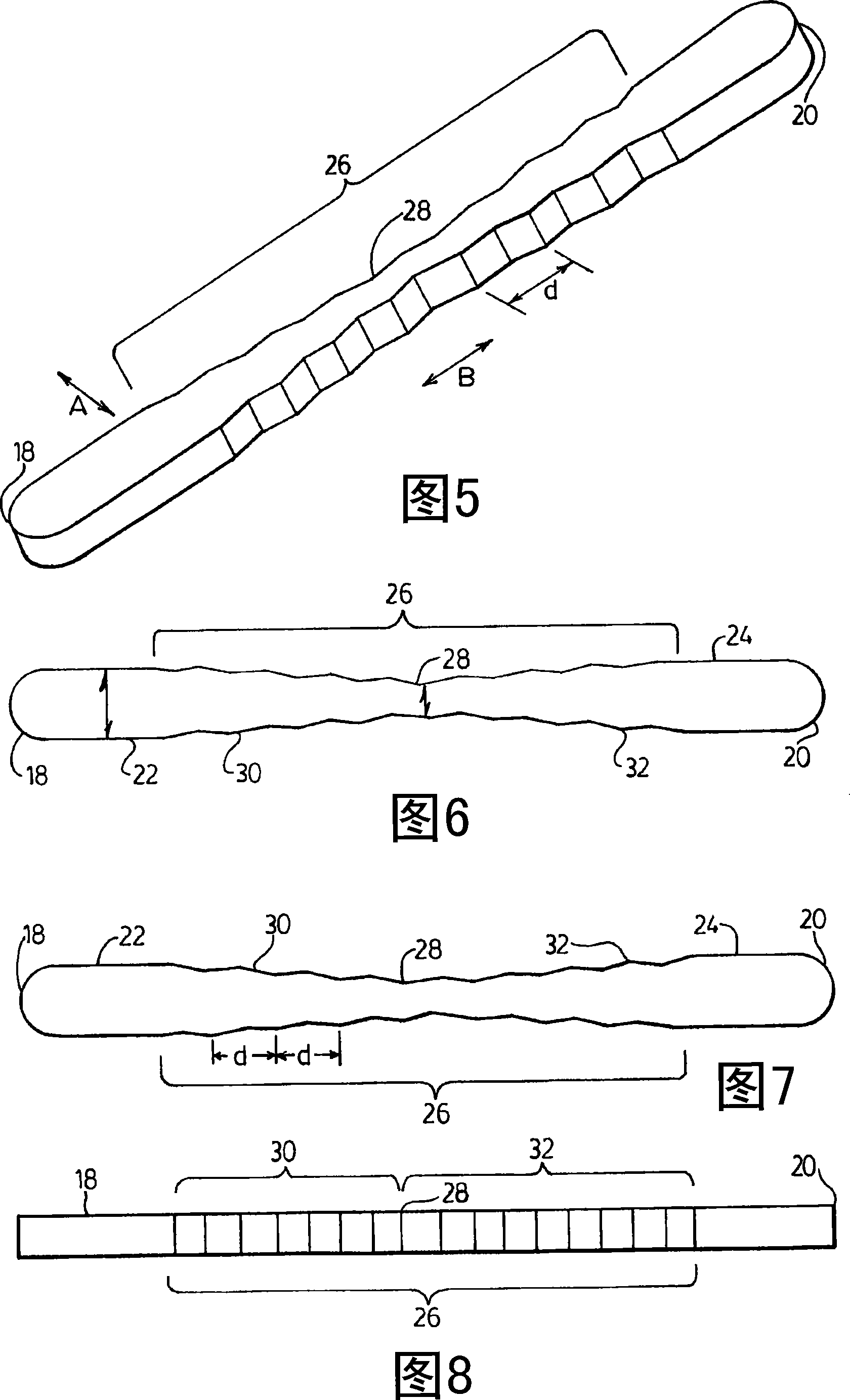

[0062] Referring also to Figures 5-8, the crossties 16 have a length of about 2.6 m between the first end 18 and the second end 20, a constant height of about 12.8 cm along The width at the ends 22, 24 is about 23 cm. Actual ends 18 and 20 are slightly rounded. The end portions 22 , 24 extend longitudinally approximately 45 cm from the ends 18 and 20 , respectively, so as to define therebetween an interior 26 of approximately 1.68 m having a central portion 28 intermediate the crossties 16 .

[0063] Interior 26 has an undulating shape formed to define a plurality of concave and convex surfaces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com