Central controlled wedge type belt type conveyer broken-belt protecting device

A belt conveyor, centralized control technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of unusable, inconvenient maintenance, overhaul, difficult operation reliability, and flexibility and other problems to achieve the effect of preventing blocking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

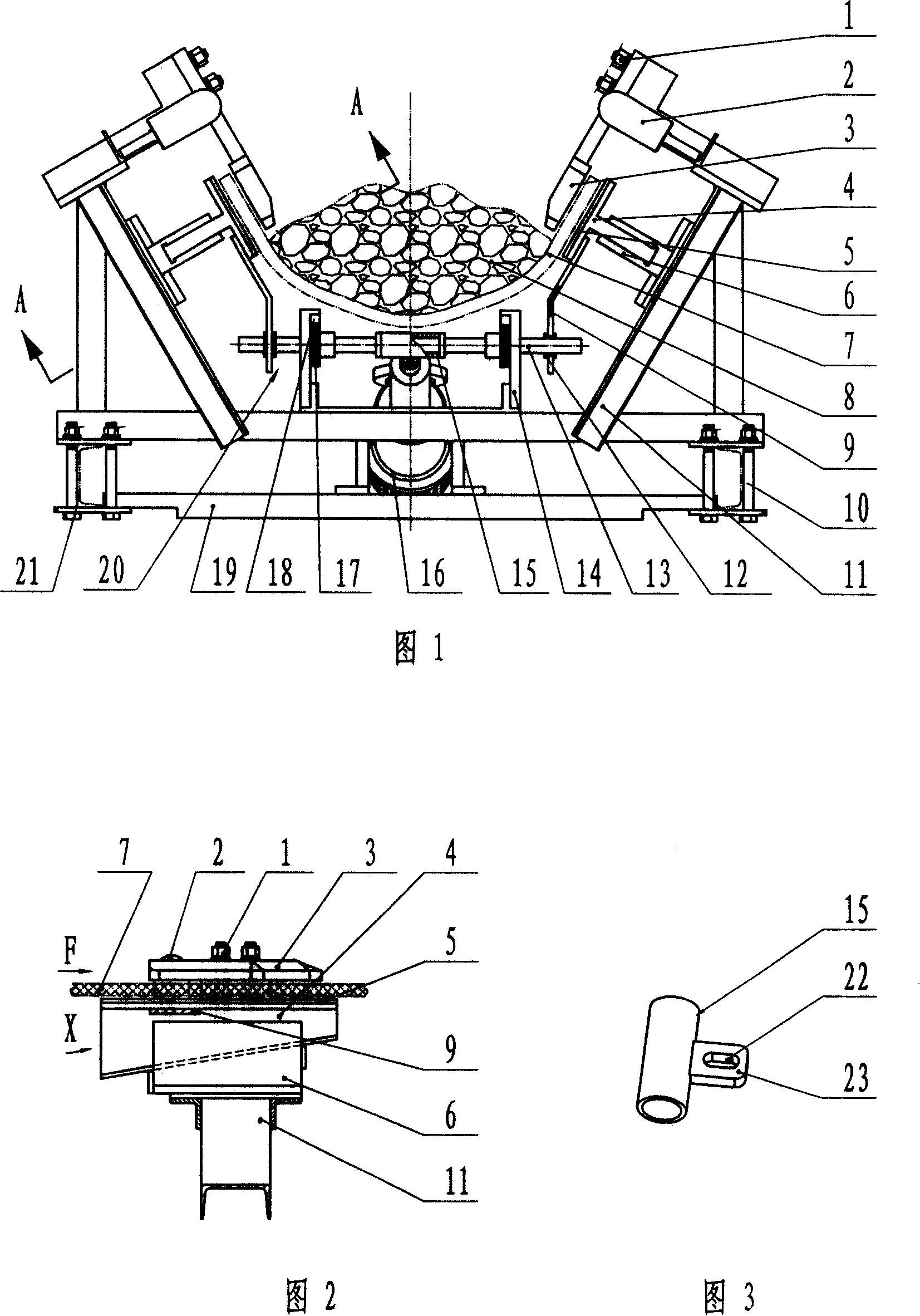

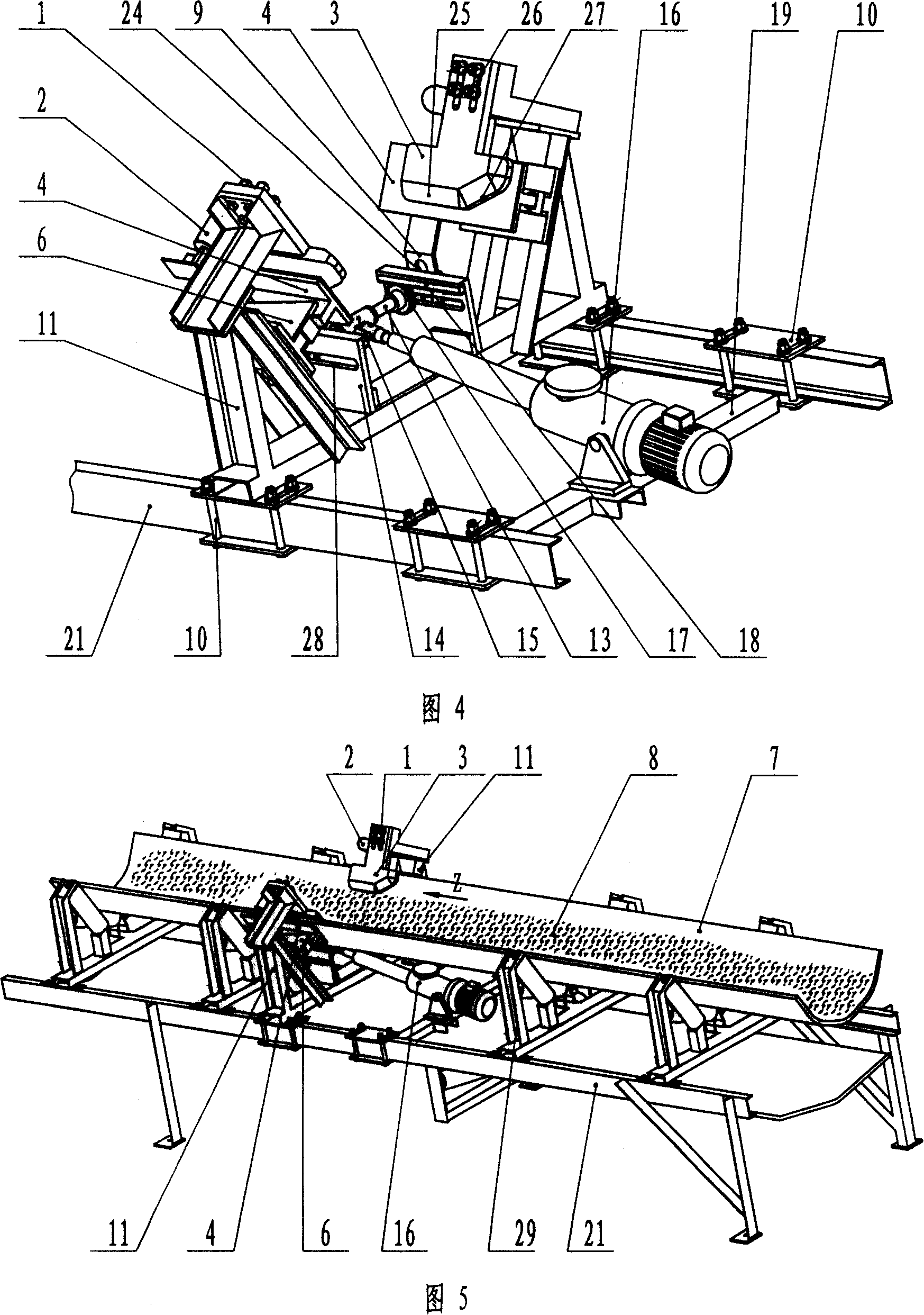

[0016] In the embodiment shown in the figure, the mounting bracket (11) is fixed on the middle frame channel steel (21) of the belt conveyor by means of a bolt group, and a wedge-shaped chute (6) is installed on both sides of the mounting bracket (11). ), the wedge-shaped gate block (4) is placed in the wedge-shaped chute (6) with the same wedge angle, and the tip of the wedge-shaped gate block (4) points to the direction in which the belt (7) is broken and slides down. The vertical top of the block (4) has respectively fixed a fixed gate block (3) on the support. The linkage device (20) connects the left and right wedge-shaped gate blocks (4), and is connected with the movable end of the linear reciprocating drive device (16) installed on the bracket (19), and the bracket (19) is fixed by a bolt group On the intermediate frame channel steel (21). The linear reciprocating motion driving device (16) used in the present embodiment shown in Fig. 1, 4, 5 is an electro-hydraulic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com