Viscose long filament monitor for bathing

A filament bath and monitor technology, which is applied to instruments, spinneret assemblies, televisions, etc., can solve the problem of inability to realize the intelligent evaluation of the number of single filament jets by image monitoring of viscose filaments, etc., and achieves convenient mechanical adjustment, satisfying The effect of fast monitoring and flexible device movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

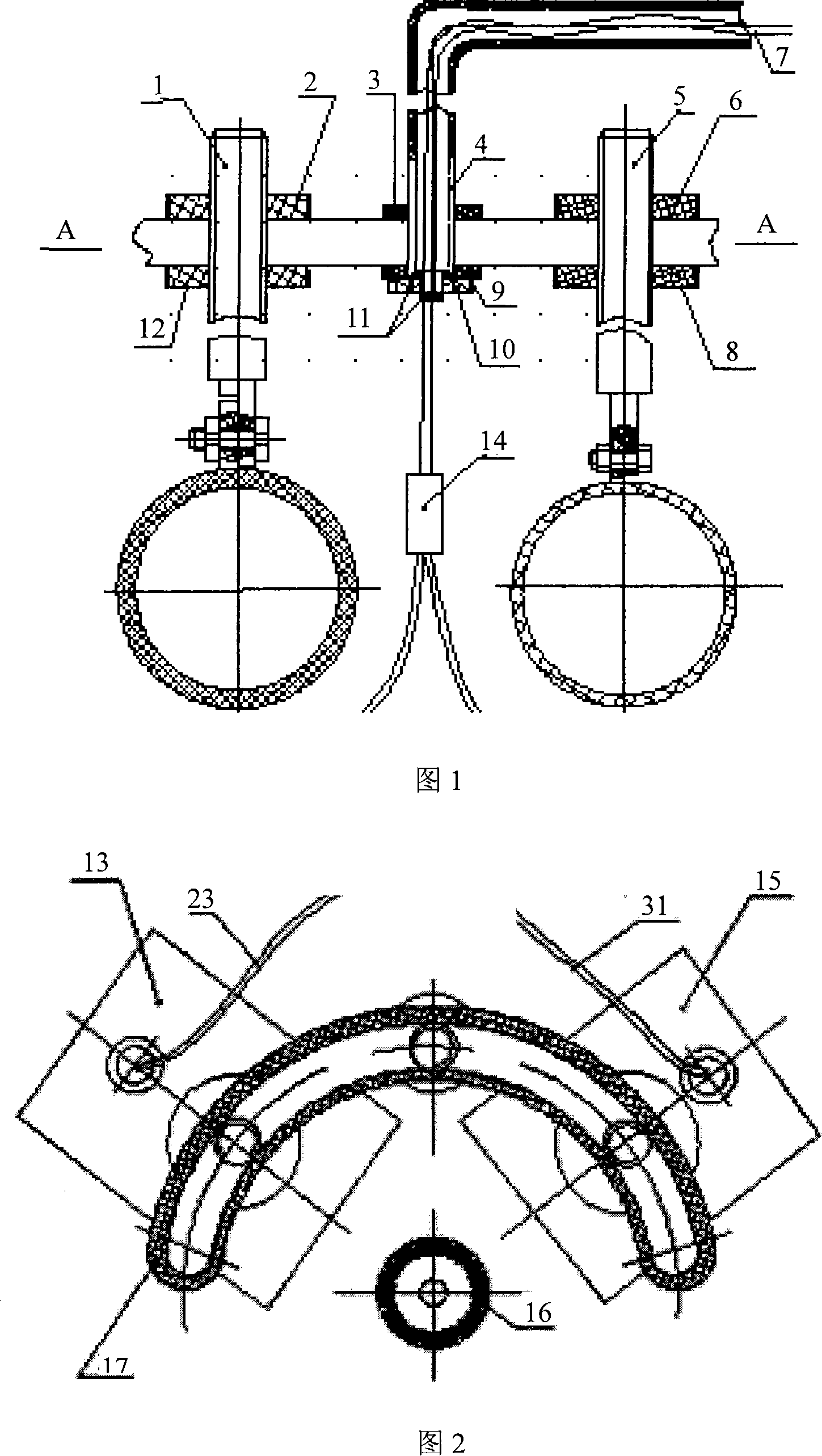

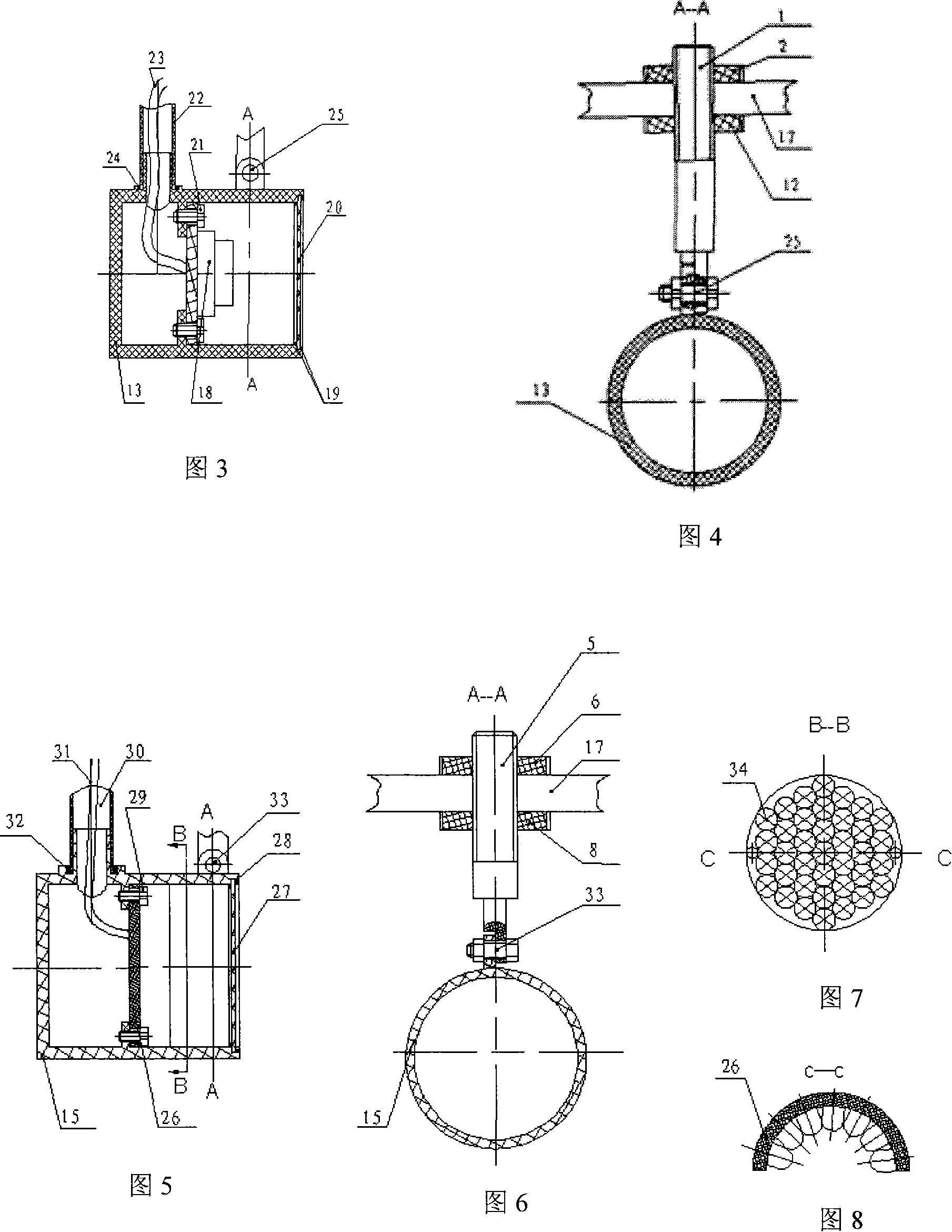

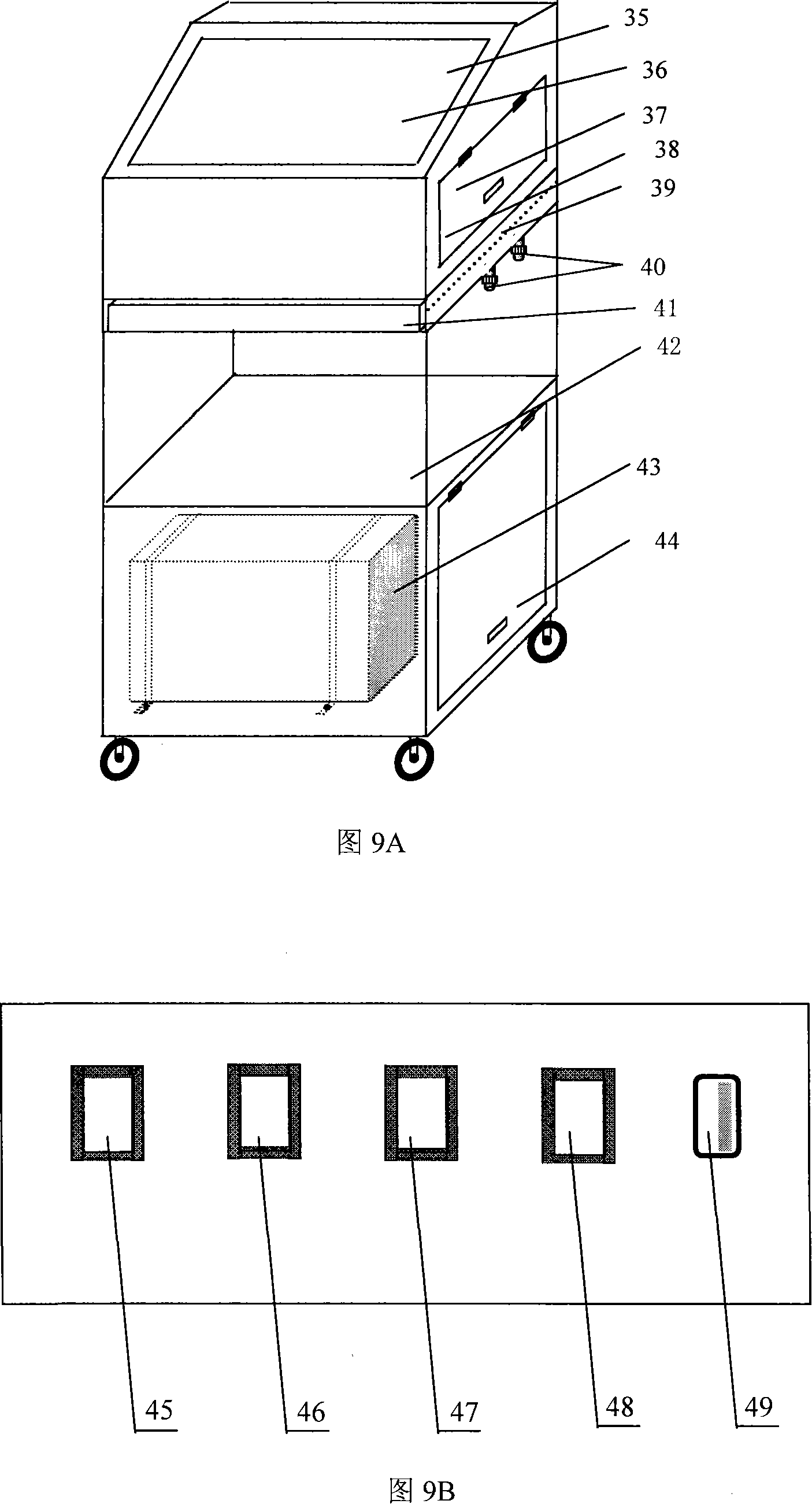

[0036] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0037] In FIG. 2 , the camera housing 13 is connected to the arc-shaped adjustment frame 17 in FIG. 2 by adjusting nut one 2 and adjusting nut six 12 through the camera fixing rod 1 in FIG. 1 . The illuminating device housing 15 is connected to the arc-shaped adjusting frame 17 in FIG. 2 by the adjusting nut three 6 and the adjusting nut four 8 through the illuminating device fixing rod 5 in FIG. 1 . The camera housing 13 and the lighting device housing 15 can move along the arc-shaped adjustment frame 17, and can also be adjusted in the vertical direction by the camera fixing rod 1 and the lighting device fixing rod 5 respectively, so as to realize the best camera shooting with respect to the spinneret 16 in Fig. 2 and lighting location. The camera output line 23 and the light source power line 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com