Device for the pivoting connection of a wiper blade to a wiper arm of a windscreen wiper

A technology of wiper arm and wiper blade, which is applied in the field of hinged connection of wiper arm, and can solve the problem of damage to corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

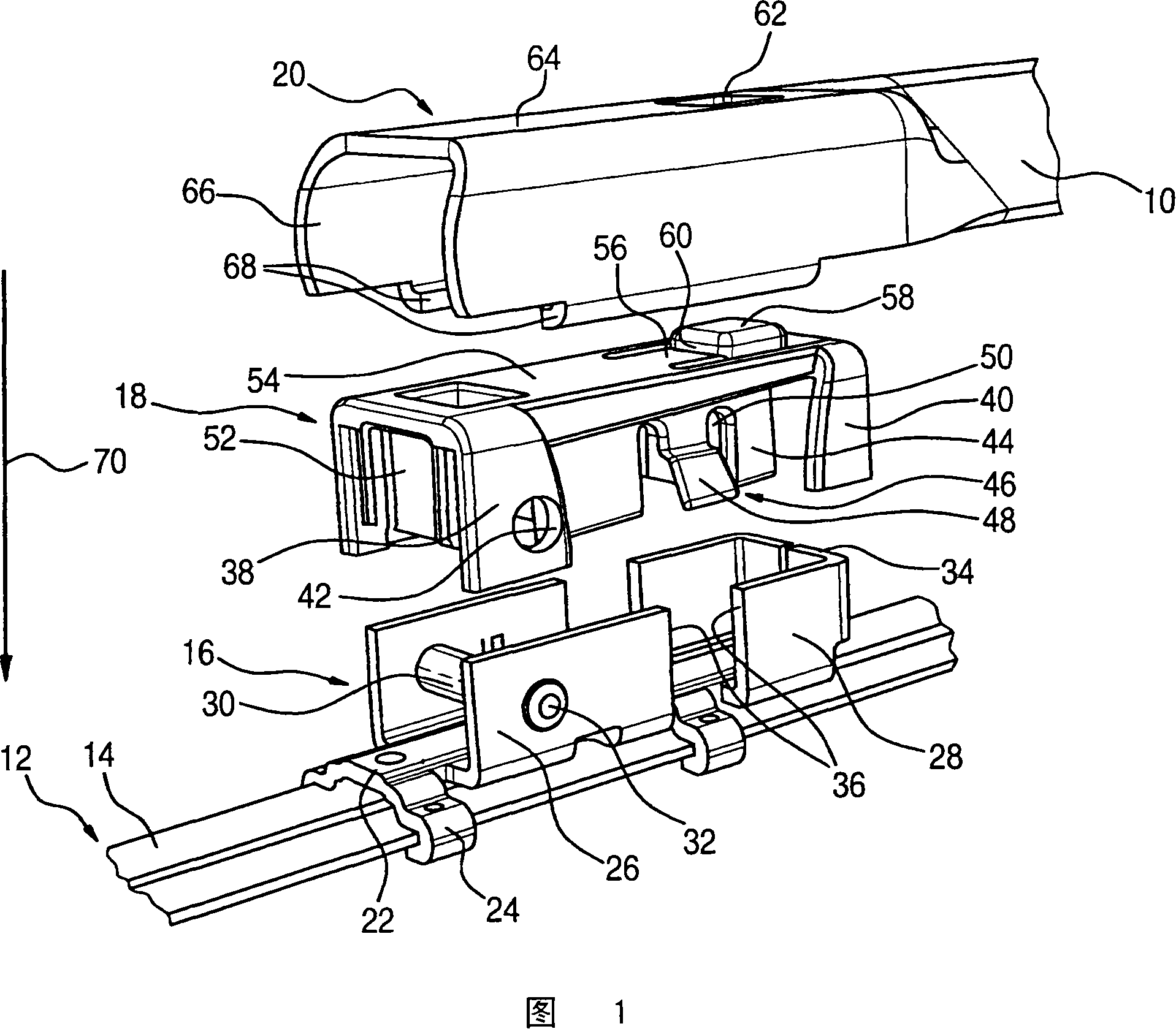

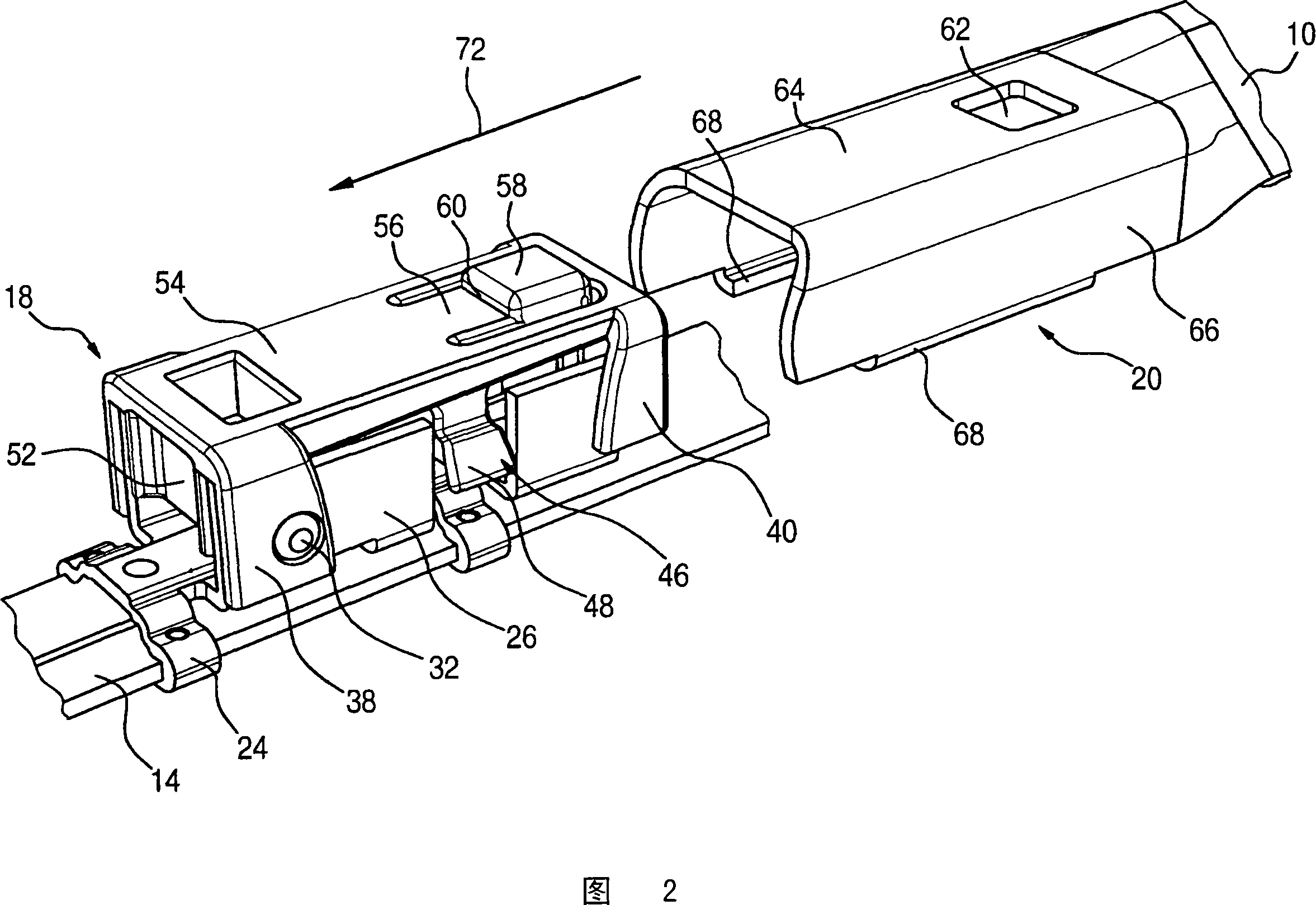

[0012] For the wiper blade 12 only two supports 14 in the form of two parallel spring bars are shown. The connecting element 16 in the form of a metal clamp is fastened to the spring strip, for example by welding and / or by means of clamps 24 . The clips are formed laterally on the base part 22 . The connecting part 16 has a substantially U-shaped cross-sectional profile, wherein on each longitudinal side the two side walls 26 , 28 are bent by approximately 90° from the base part 22 away from the support part 14 . A recess 36 is provided between the longitudinal side walls 26 , 28 of the connecting element 16 . The side wall 26 pointing toward the free end of the wiper blade 12 supports a bearing bolt 30 . The bearing bolt 30 protrudes laterally outward beyond the side wall 26 with a bearing head 32 . The side wall 28 at the other end of the adapter 18 is bent inwards at the drive-side end by approximately 90° and forms an end wall 34 .

[0013] The adapter 18 is mounted pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com