Auxiliary means for changing porcelain insulator of telegraph pole

A technology of auxiliary tools and utility poles, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor intensity, long power outage time, and long operation time, so as to improve safety and convenience, improve work efficiency, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

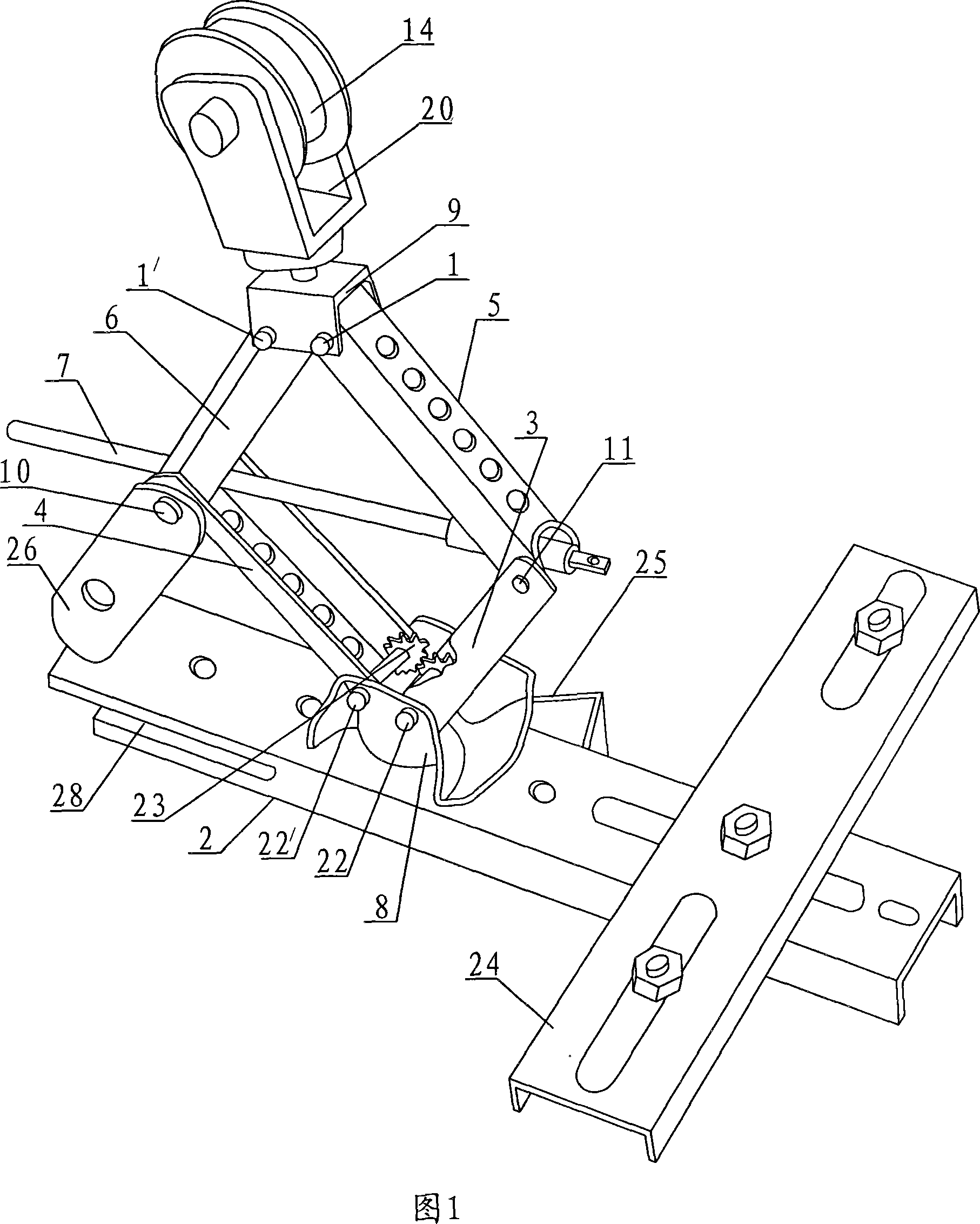

Embodiment 1

[0032] Embodiment 1, as shown in FIG. 1 , the top wire mechanism includes a U-shaped mounting frame 20 and a top wire pulley 14 , the mounting frame 20 is connected to the upper base 9 , and the top wire pulley is installed on the mounting frame 20 . When the porcelain bottle 27 on the top pole was damaged, as shown in Figure 7, the base 2 was positioned on the utility pole cross arm 29. Sleeve the handle on the joint at the end of the adjusting screw rod 7, turn the handle to rotate the adjusting screw rod 7, shorten the distance between the two shaft pins 10, 13, lift the top line pulley 14 and remove the wires on the porcelain bottle 27, and move After opening the electric wire 28, the top line pulley supports the electric wire 28 again, and after the electric wire 28 leaves the porcelain bottle 27, the porcelain bottle 27 can be changed. Electric wire 28 is removed from porcelain bottle 27 by auxiliary tool, has reduced labor intensity. After the replacement is completed,...

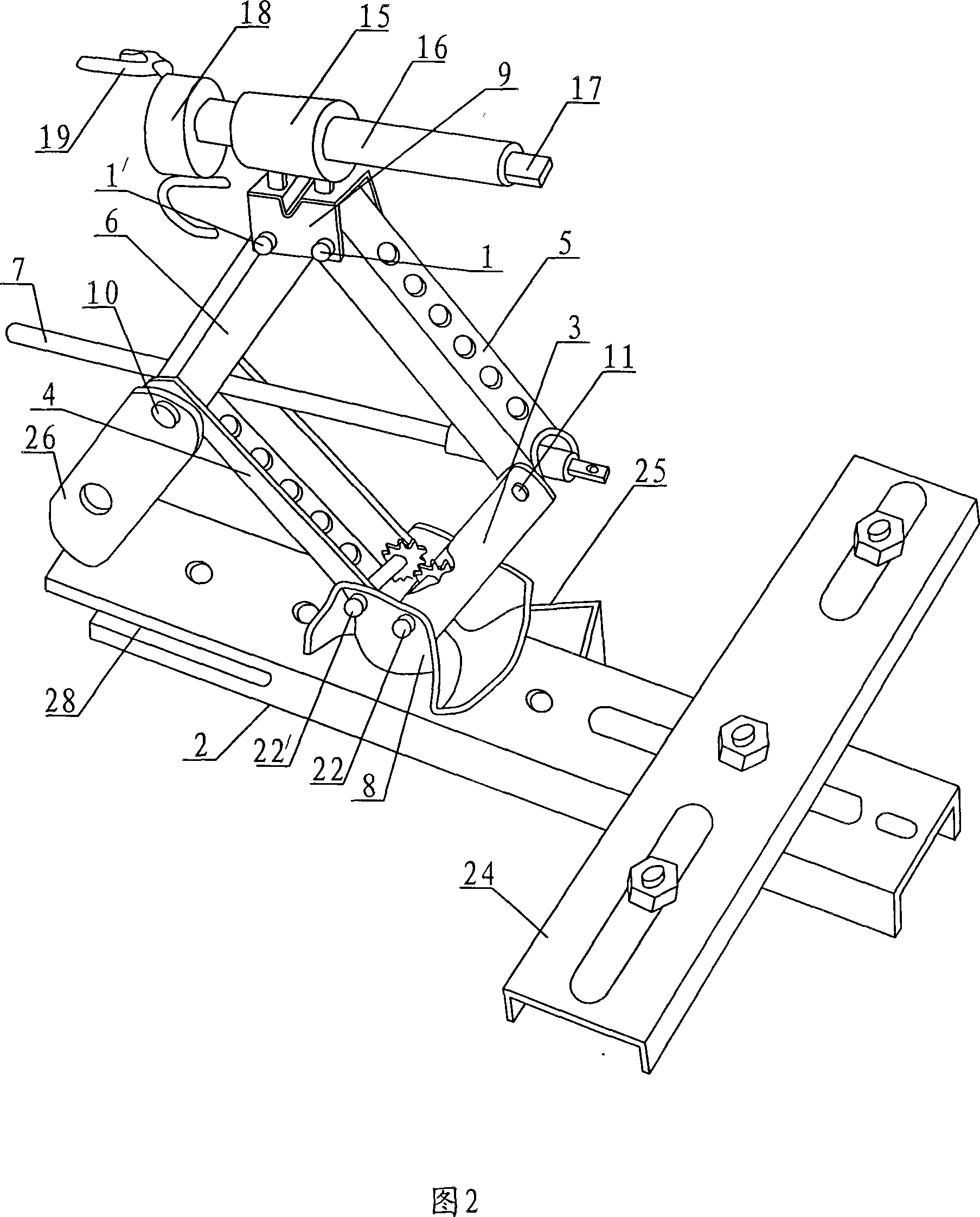

Embodiment 2

[0033] Embodiment 2, as shown in Figure 2, the top line mechanism includes a sleeve 15, a screw rod 16 and a U-shaped top line fork 19, the sleeve 15 is horizontally fixed on the upper base 9, and the screw rod 16 is threaded in the sleeve 15 , The top thread fork 19 is arranged at one end of the screw rod 16, and the other end of the screw rod 16 is provided with a rotary joint 17. This structure is mainly used to remove the wires on the outer porcelain bottle of the corner rod, and the top wire fork is raised to contact with the wires by adjusting the screw rod, and then the screw rod is rotated to push the screw rod forward and sideways to push out the wires.

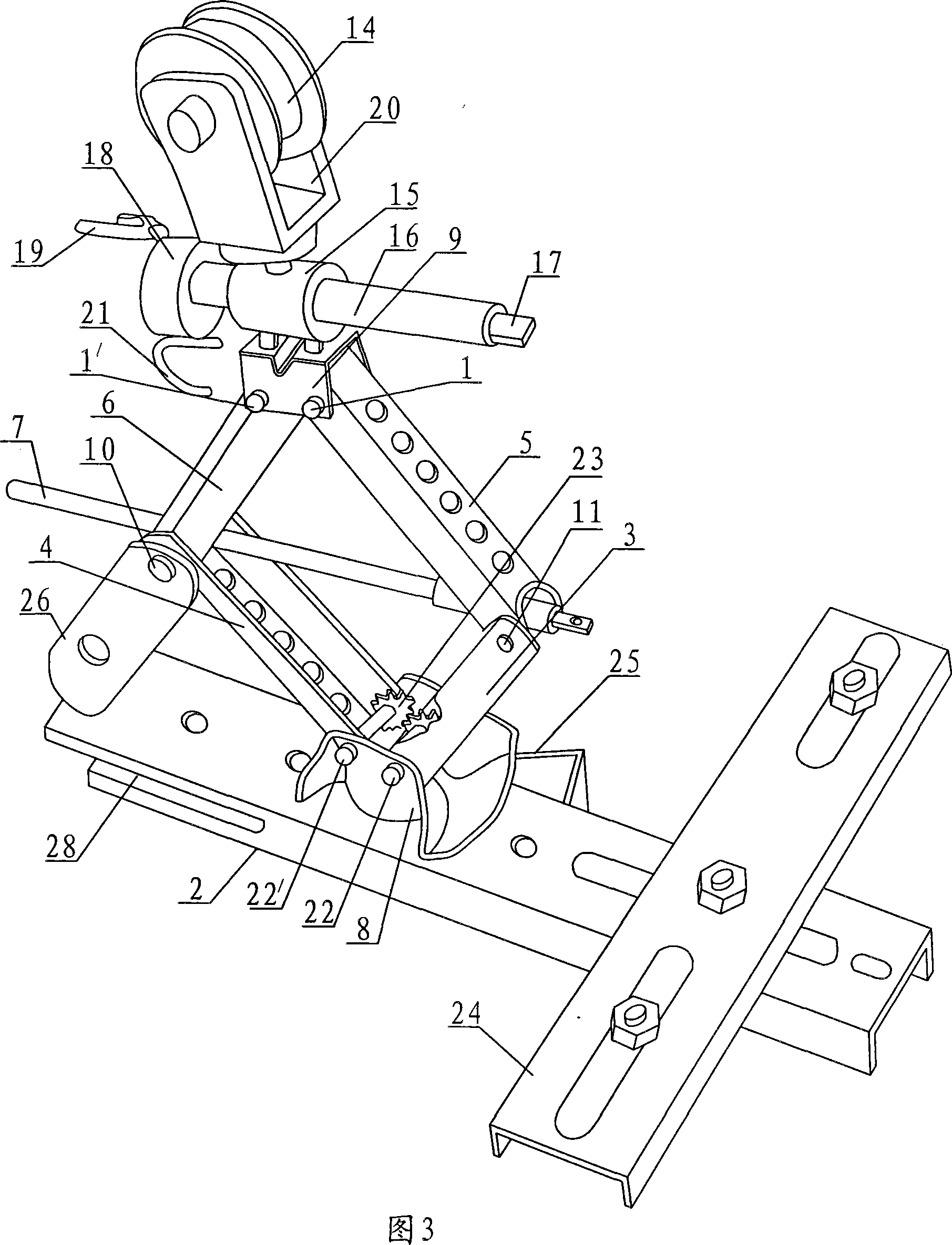

Embodiment 3

[0034]Embodiment 3, as shown in Figure 3, the top line mechanism includes a sleeve 15, a screw rod 16, a U-shaped mounting bracket 20 and a top line pulley 14; the sleeve 15 is horizontally fixed on the upper base 9, and the screw rod 16 is threaded on the sleeve In the cylinder 15, one end of the screw rod 16 is provided with a rotary joint 17, and the other end is threadedly connected with a mounting sleeve 18, and a top wire fork 19 is arranged on the mounting sleeve 18; the mounting bracket 20 is connected to the sleeve 15, and the top wire pulley 14 is installed on the mounting bracket 20. A U-shaped cable hook 21 can also be set on the mounting sleeve 18 simultaneously. This structure can not only be used to remove the electric wire on the top rod porcelain bottle, but also can be used to remove the electric wire on the corner rod porcelain bottle. The working principle for removing the wires on the porcelain vase on the top rod is the same as that of embodiment 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com