A foaming instrument

A technology of tools and liquid inlet valves, which is applied in the direction of injection devices, building maintenance, liquid injection devices, etc., can solve problems such as shortened service life, waste of resources, and unsatisfactory sealing degree, so as to prolong service life, save resources, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

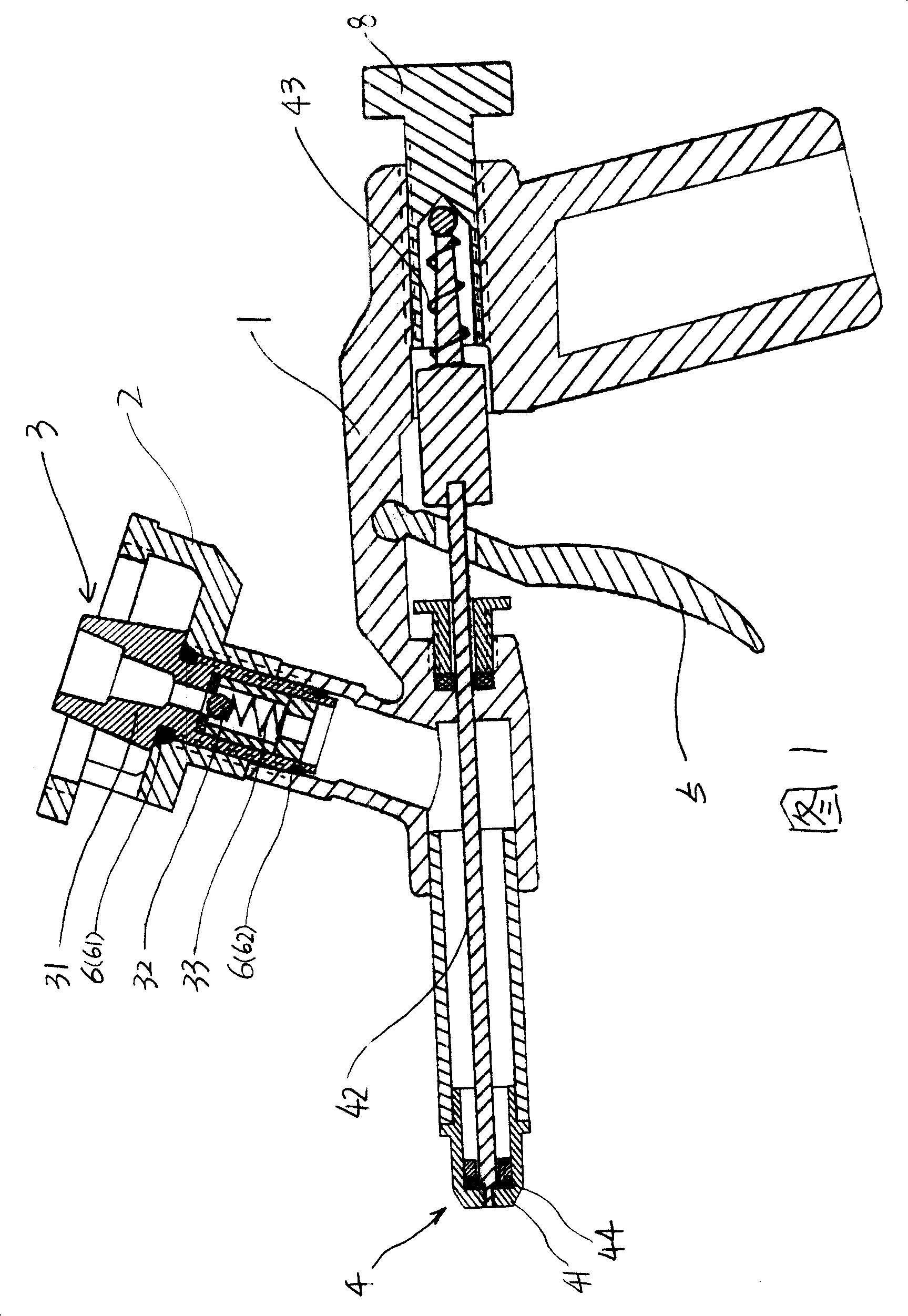

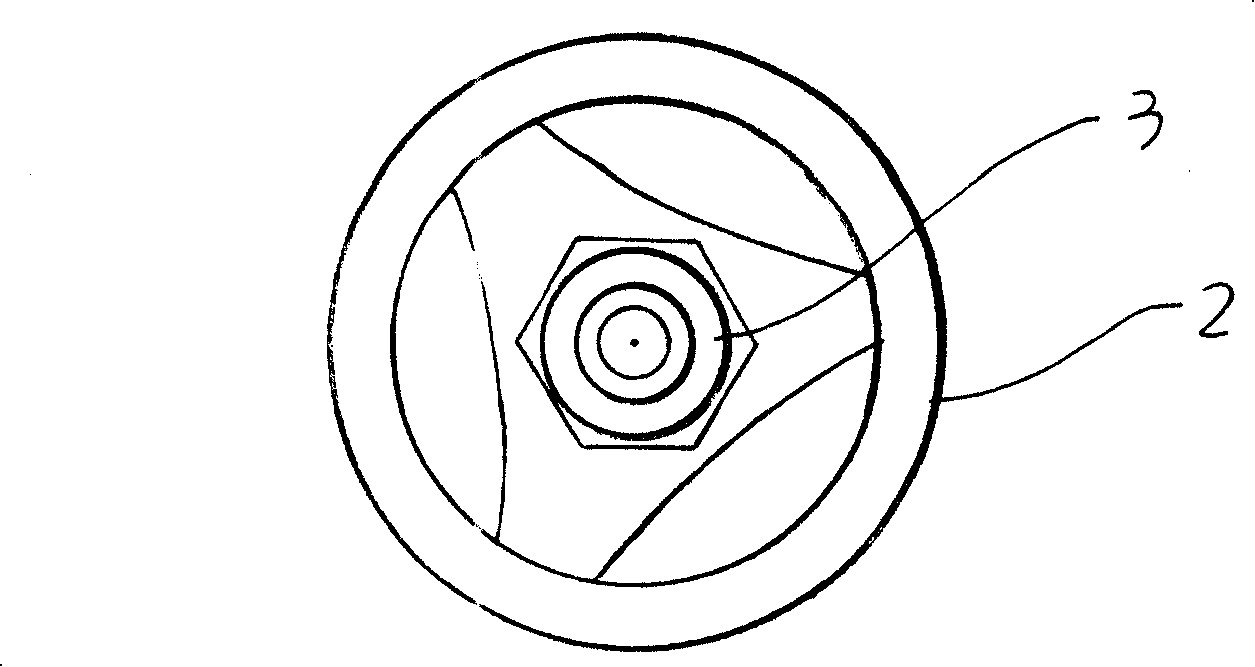

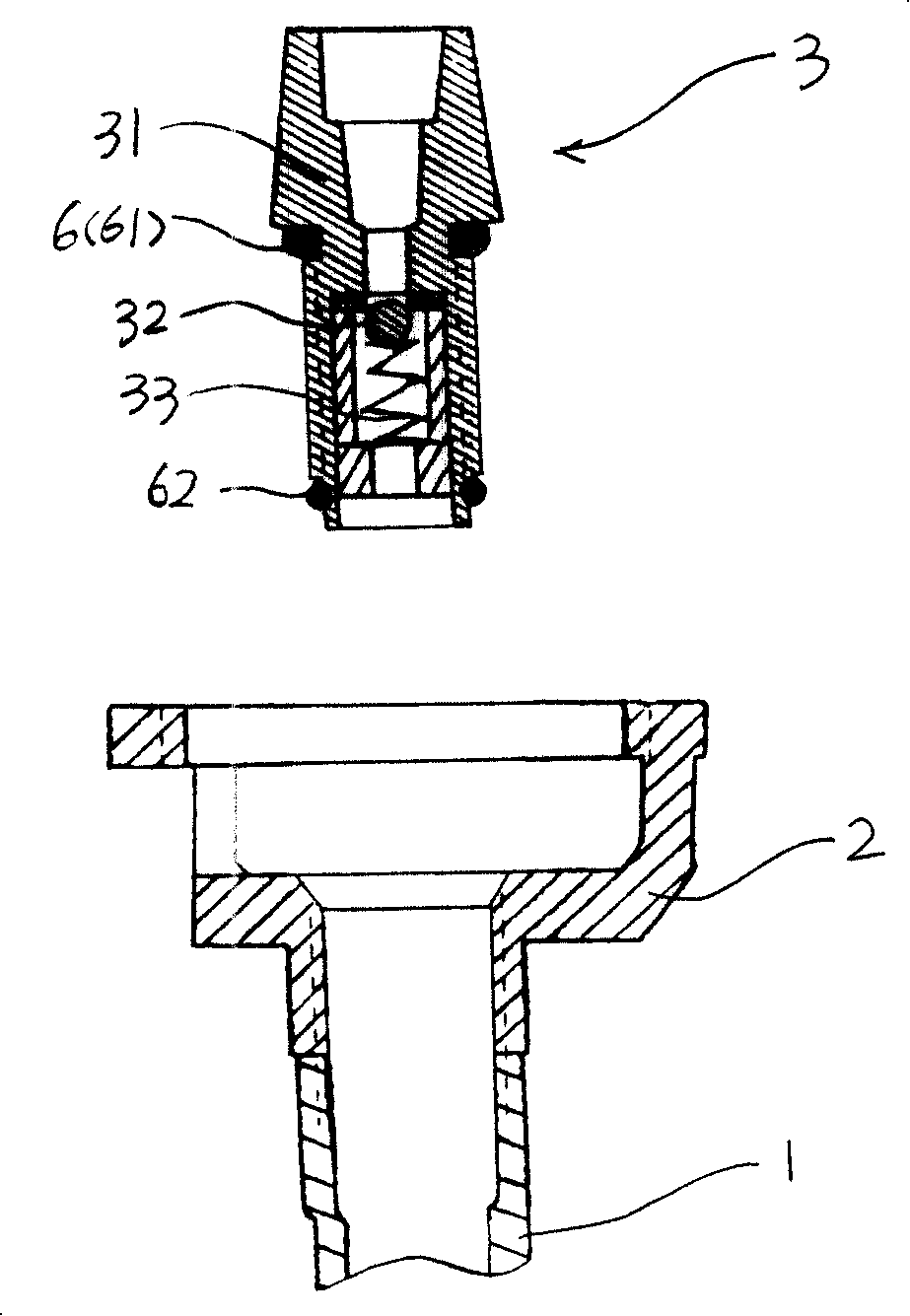

[0022] A foaming tool of the present invention comprises a housing 1, a connecting piece 2, a liquid inlet valve 3, a liquid outlet valve 4 and a switch device 5, the switch device 5 can enable or close the liquid outlet valve 4, and is characterized in that: The liquid outlet valve 4 and the casing 1 and / or the connecting piece 2 can be made into separate structures; a sealing device 6 is also provided between the liquid inlet valve 3 and the connecting piece 2 or the casing 1 .

[0023] The liquid inlet valve 3 may include a liquid inlet nozzle 31 , a closing member 32 and a spring device 33 .

[0024] The liquid outlet valve 4 may include a liquid outlet nozzle 41 , a valve core 42 and a spring device 43 . A seal 44 may also be included.

[0025] See Figure 1 and image 3 , the liquid outlet valve 3 is made into a split structure with the housing 1 and the connecting piece 2, and a sealing device 6 is provided between the liquid inlet valve 3 and the connecting piece 2, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com