Electric tying machine

A kind of tying machine and electric technology, which is applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of complex structure, easy failure and high cost, and achieve the effect of simplifying the structure, reducing the failure rate and facilitating the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

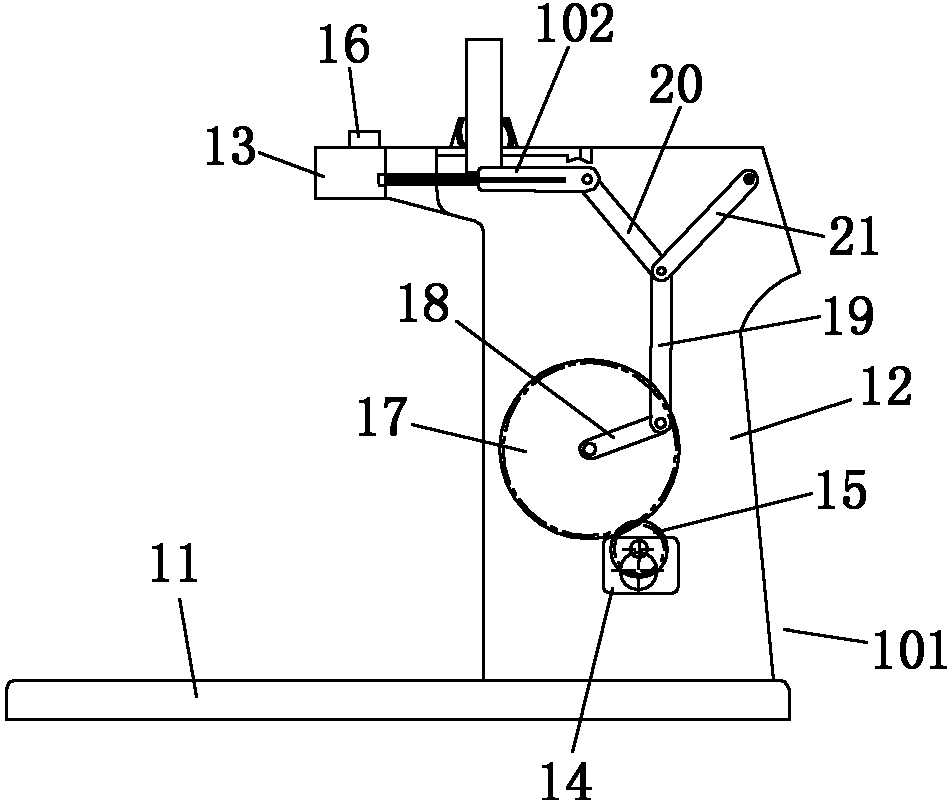

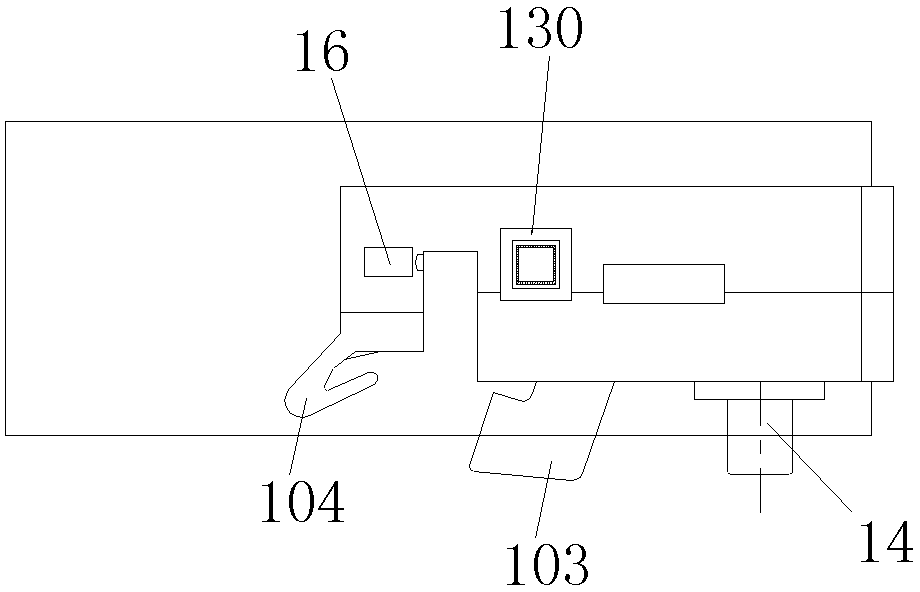

[0018] Examples of electric tying machines, such as Figure 1-2 As shown, the electric binding machine includes a frame 101, a push rod 102 and a push rod driving mechanism.

[0019] The frame 101 comprises a base 11, a stand 12 and a cross arm 13, the cross arm 13 is provided with a nail inlet 130, and the push rod is assembled on the cross arm 13, wherein the structure of the nail inlet 130, the push rod 102 and The relative positional relationship between the nail inlet 130 and the push rod 102 is the prior art, and will not be described in detail here. In addition, the cross arm 13 is also respectively provided with a bag pressing block 103 and a blade 104, wherein the bag pressing block 103 and the The blade 104 is also a prior art, and will not be repeated here.

[0020] The push rod driving mechanism includes a power part and a transmission part, and the power part includes a motor 14. In this embodiment, the motor 14 specifically adopts a geared motor, which can be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com