Flow barrel polishing device and polishing method

一种滚筒抛光、内筒的技术,应用在表面抛光的机床、磨削/抛光设备、磨床等方向,能够解决抛光能力和抛光效率下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

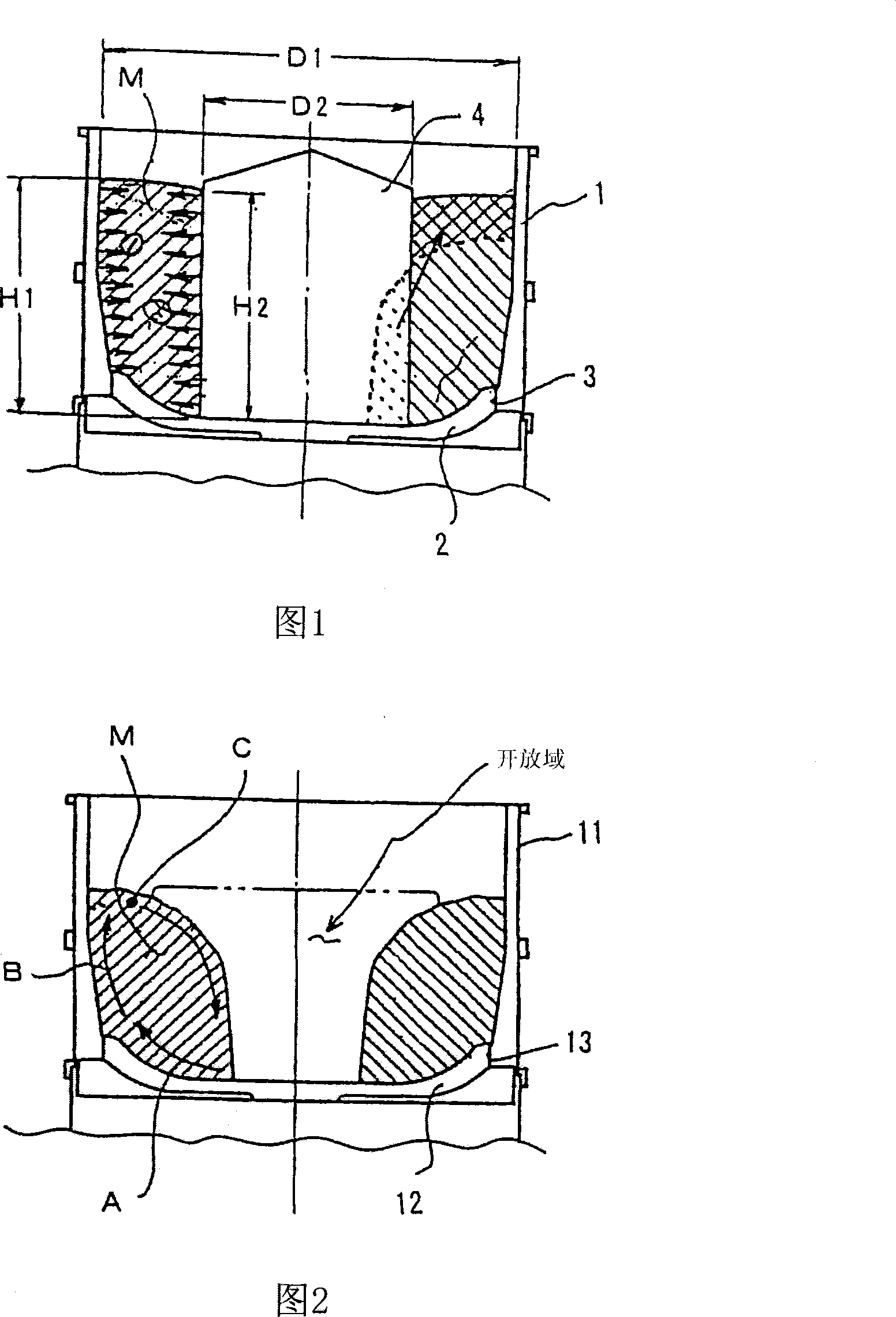

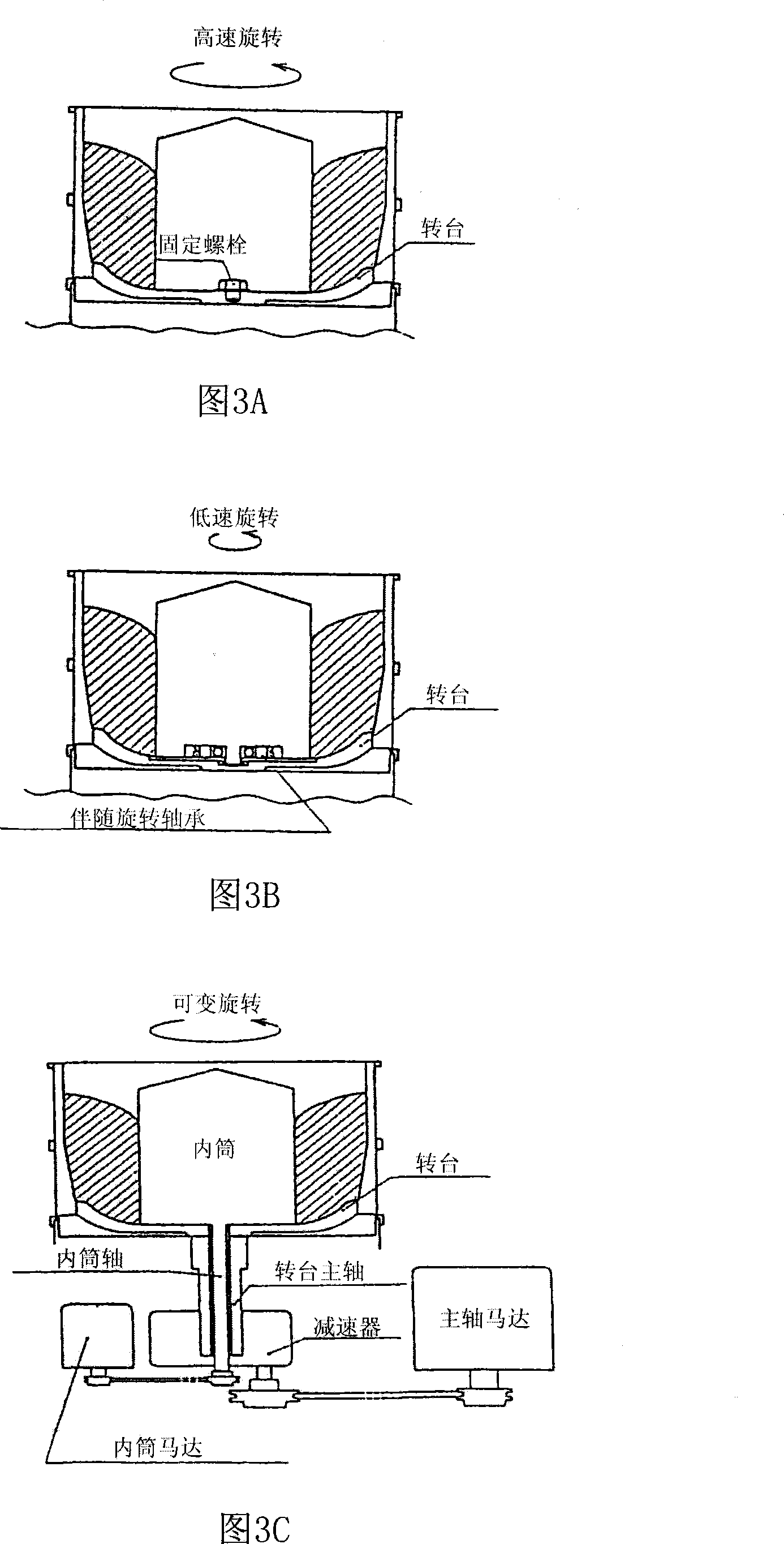

[0045]The flow tumbling apparatus shown in Table 1 was tested. In Example 1 and Example 2, an inner cylinder 4 is respectively arranged at the rotation center of the turntable 2, while Comparative Example 1 is not provided with an inner cylinder. The common test conditions are that the hard sample as the object to be polished (hereinafter, written as "workpiece") is made of material S45C, and the soft sample is made of material A2017, which is used as an abrasive material (hereinafter, written as "medium") There is a conical material with a base diameter of 20mm, a composite abrasive, and water, and the rotation speed of the turntable 2 is 250min -1 , The polishing time is 30min.

[0046] The diameter of the inner cylinder 4 in Embodiment 1 and Embodiment 2 is Φ220mm. In embodiment 1, inner cylinder 4 is tightly fixed on the rotation center of this turntable 2, as shown in Figure 1, its rotational speed is identical with this turntable 2 (250min -1 ). In Embodiment 2, the ...

Embodiment 3、4 and 5

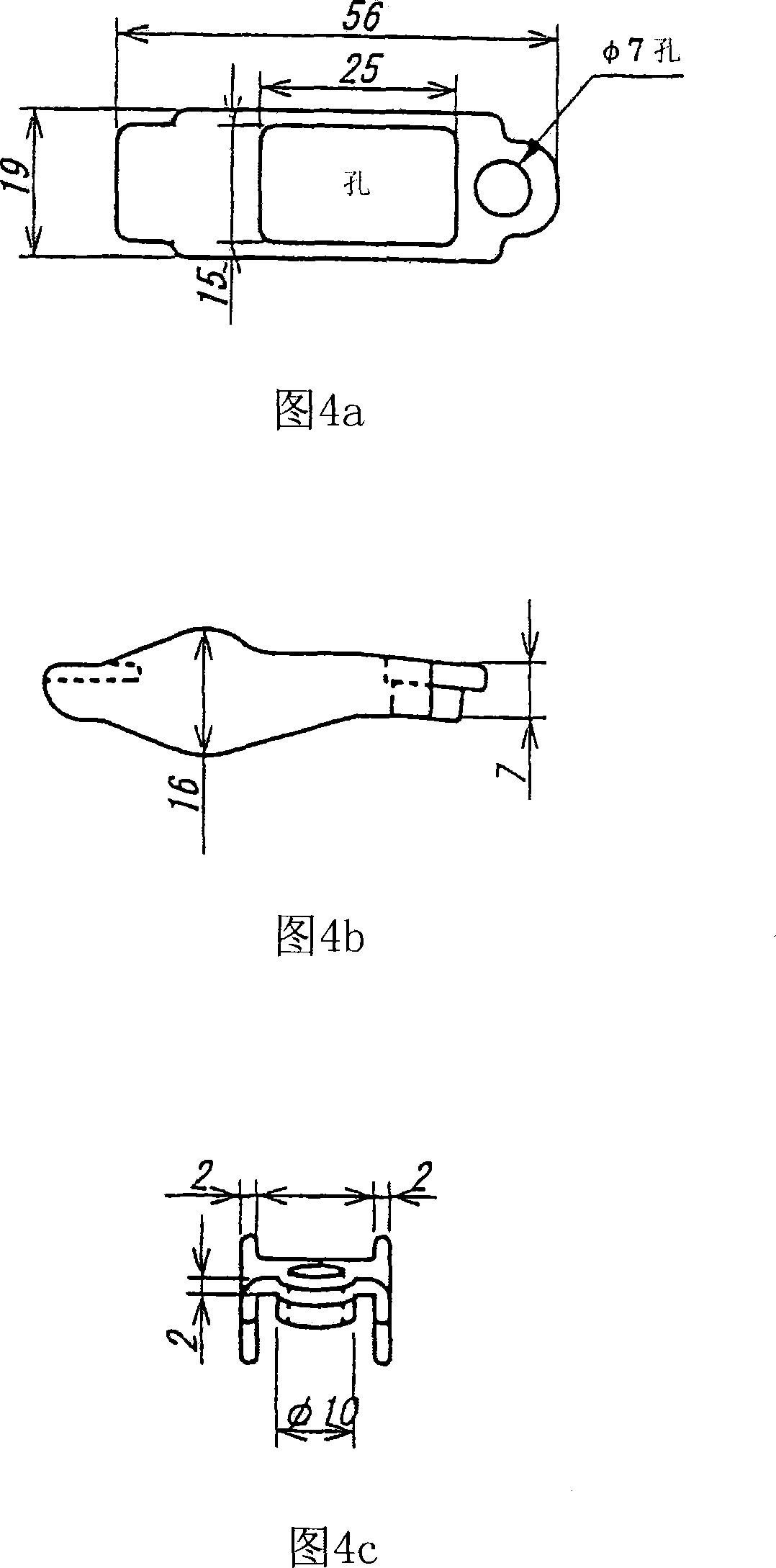

[0065] The flow tumbling apparatus listed in Table 3 were tested. Embodiments 3, 4 and 5 each have an inner cylinder 4 disposed at the rotation center of a turntable 2 . However, Comparative Example 2 did not have an inner cylinder. The common test conditions were an actual workpiece, a rocker arm made of SCM used as an automobile part, as an object (workpiece) to be polished. A test piece made of the same material as the actual workpiece is used as a reference. Than in embodiment 1 and embodiment 2 harder, smaller, have the fired ceramics of larger specific gravity, a composite abrasive and water, as medium. The rotation speed of turntable 2 is 250min -1 , The polishing time is 30min. This workpiece is used as a rocker arm of an automobile part, and its shape is shown in Figure 4.

[0066] In Examples 3 and 4, the outer diameter of the inner cylinder 4 is 220 mm, which is the same as in Examples 1 and 2. In Embodiment 5, the outer diameter of the inner cylinder is 260 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com