Brushless motor

A stepping motor and rotor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the number of parts, high cost of devices, and difficulty in implementation, and achieve the effect of high quietness and high quietness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

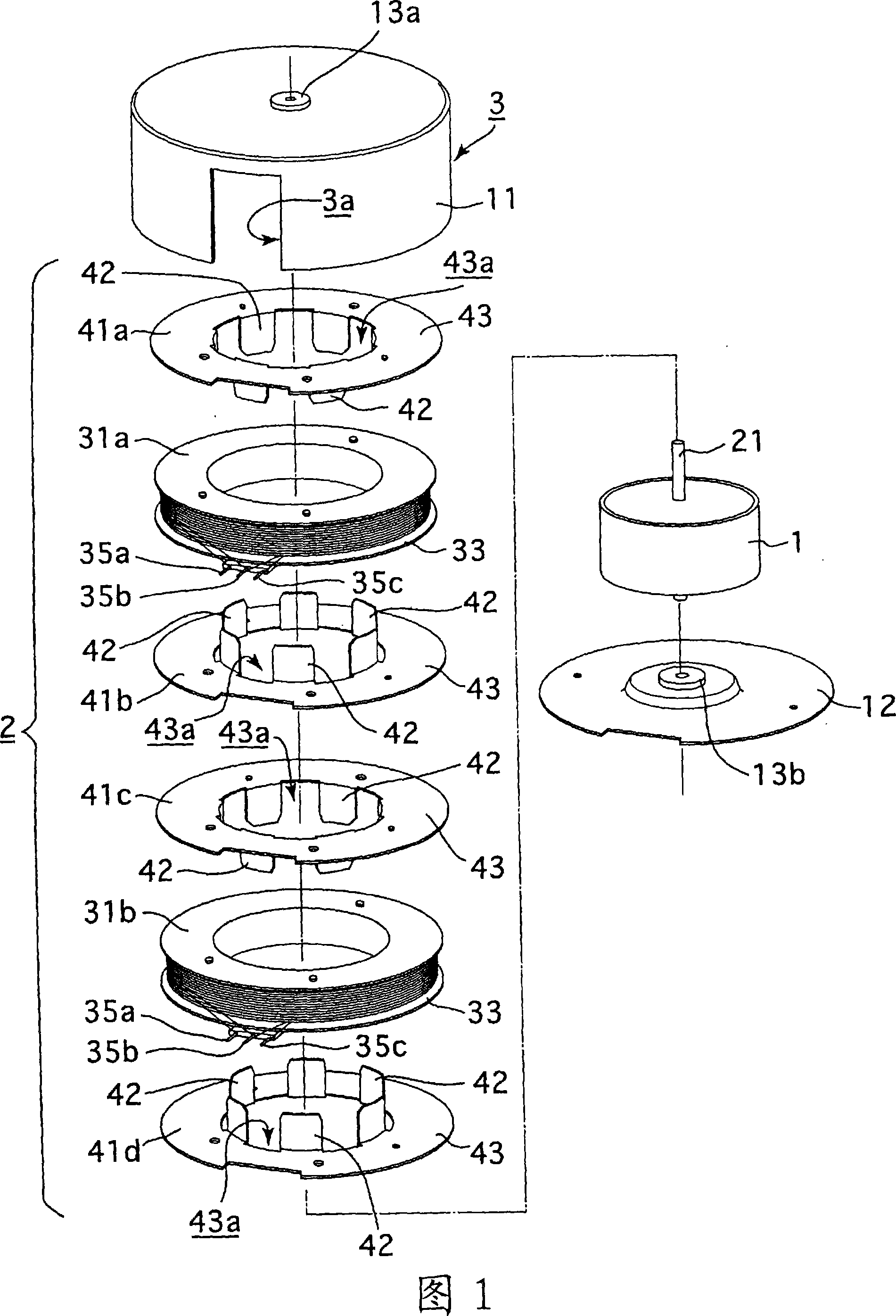

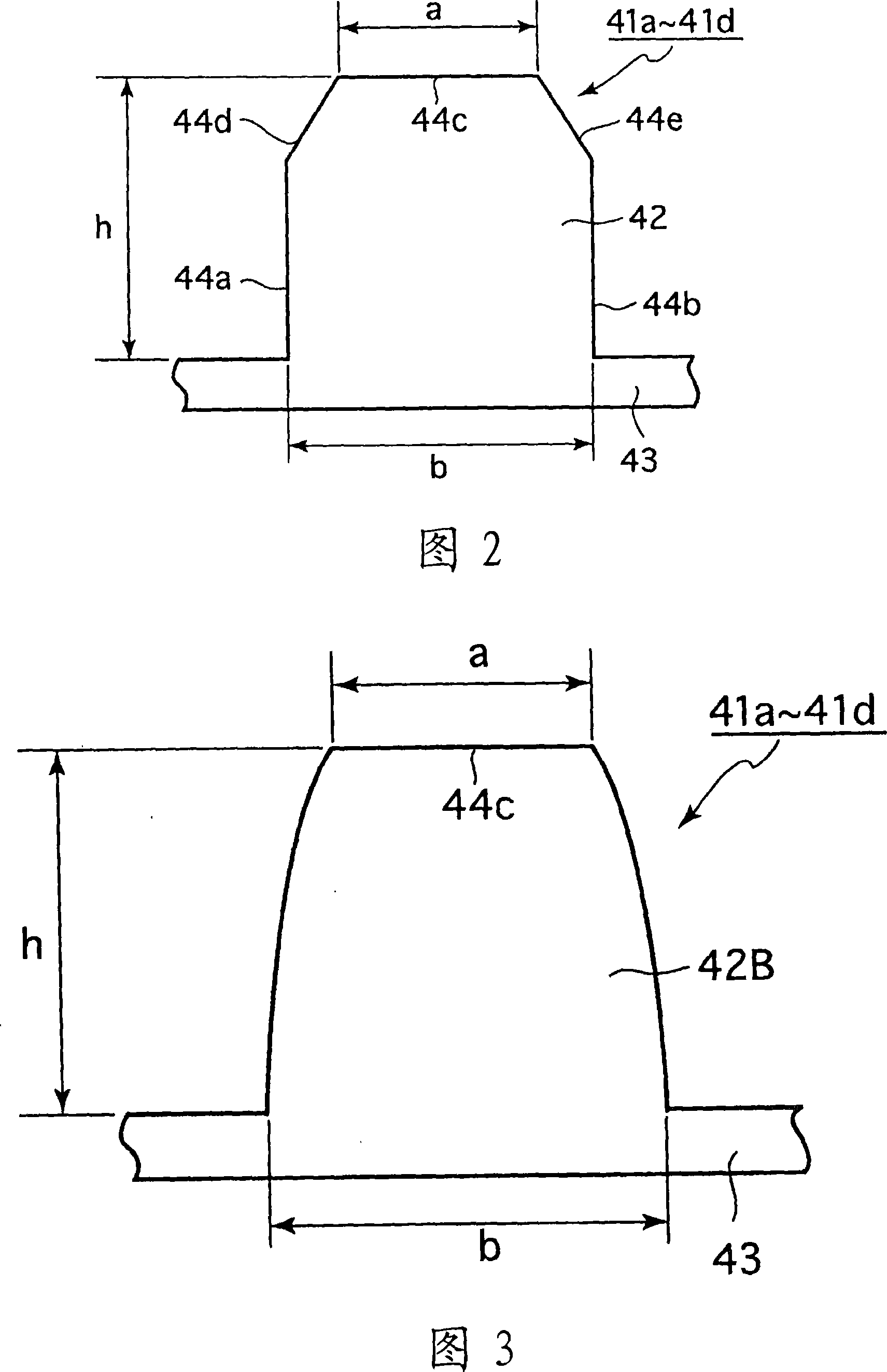

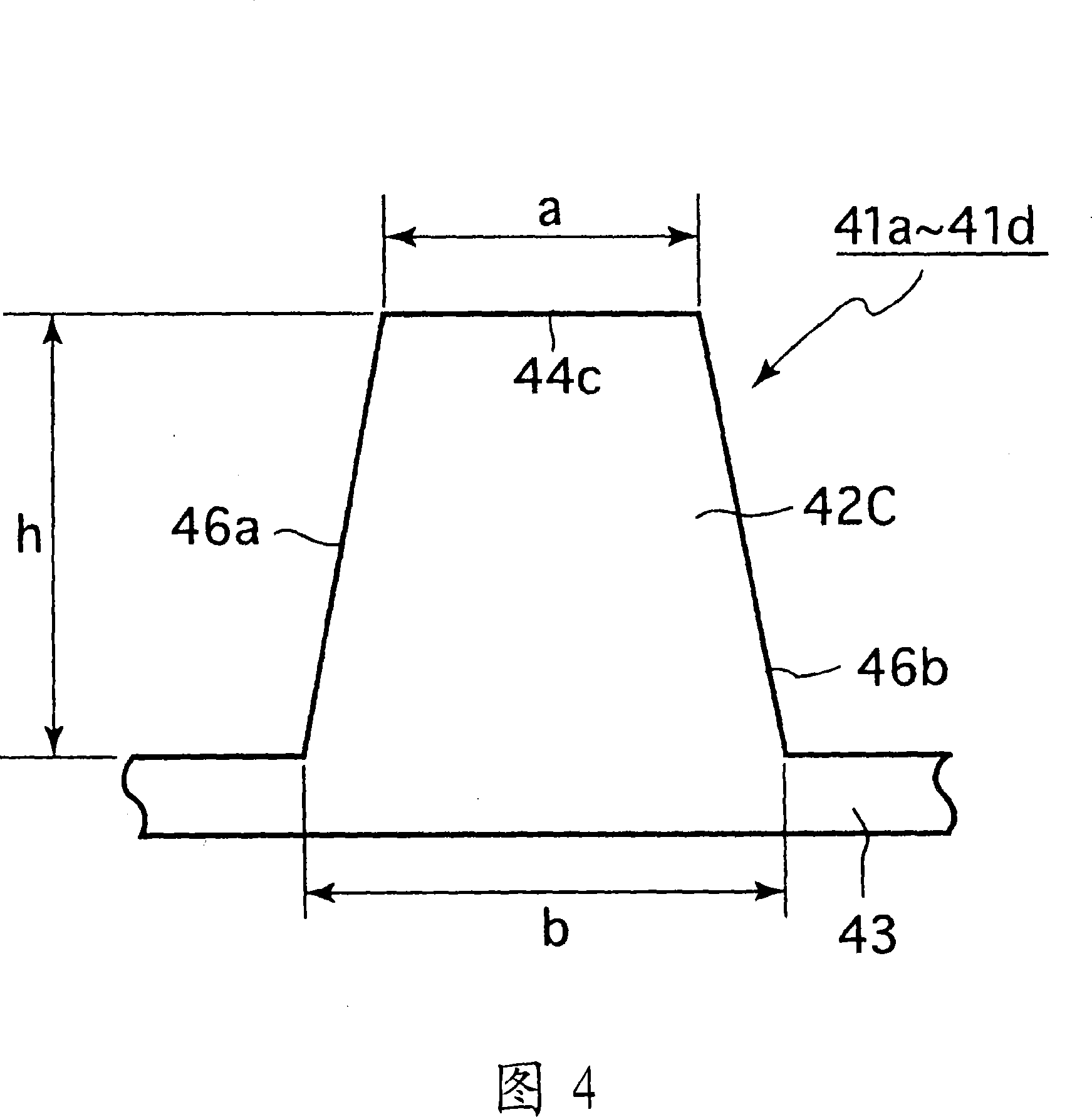

[0026] Embodiments of the present invention will be described below with reference to FIGS. 1 to 7 .

[0027] In addition, members, arrangement|positioning, etc. which are demonstrated below do not limit this invention, Various changes are possible within the scope of the present invention.

[0028] First, an example of the overall configuration of the stepping motor according to the embodiment of the present invention will be described with reference to FIG. 1 .

[0029] The stepping motor described in the embodiment of the present invention is a salient pole permanent magnet type stepping motor. Specifically, its basic structure is different from that of conventionally known ones except for the shape of salient poles (magnetic pole teeth) described later. The basic structure of stepper motors is the same.

[0030] That is, the stepping motor according to the embodiment of the present invention is roughly composed of a rotor 1 rotatably accommodated in a housing 3 and a stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com