Compressed air brake cylinder

A technology of compressing air and brake cylinders, applied in the direction of brakes, brake components, brake types, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

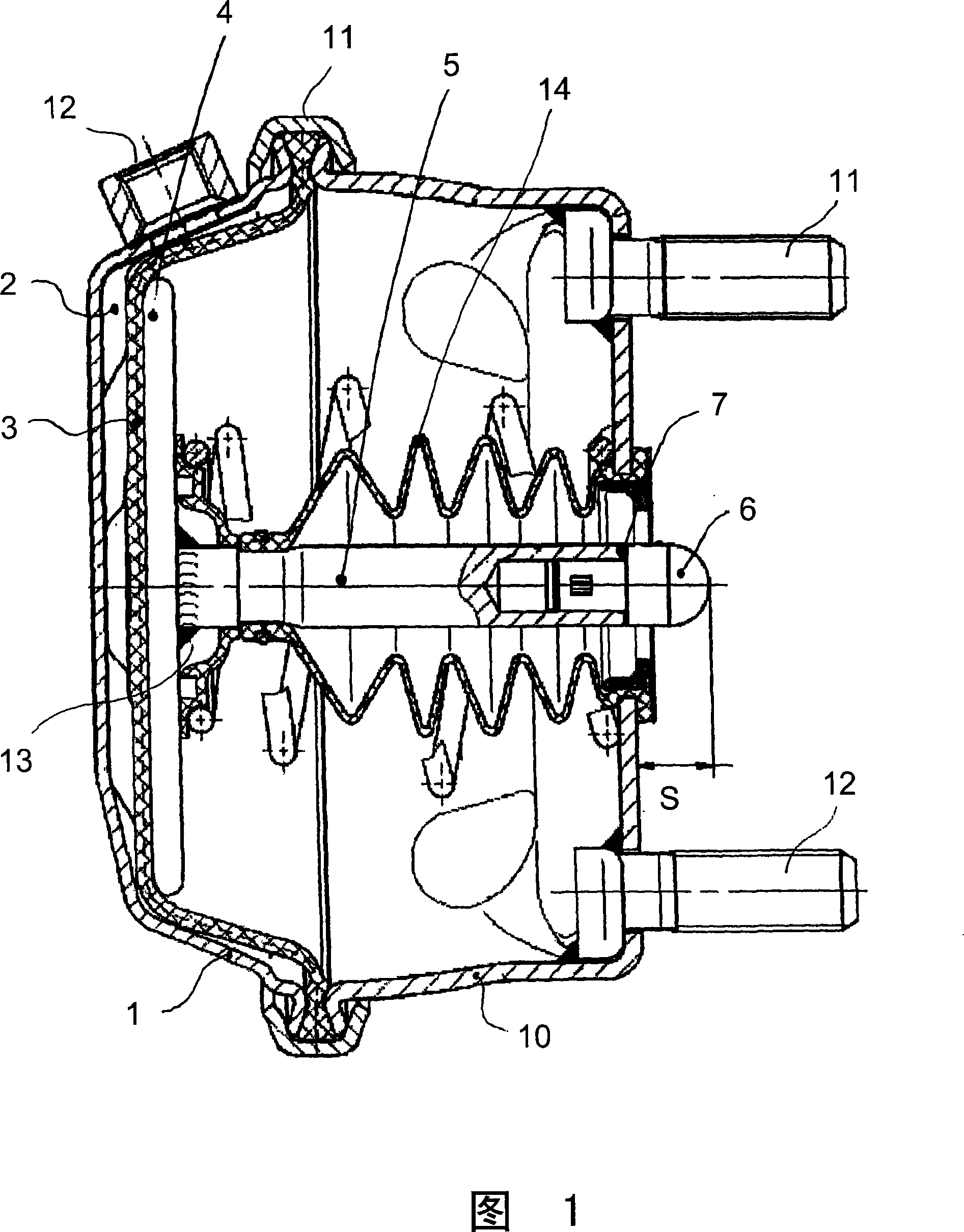

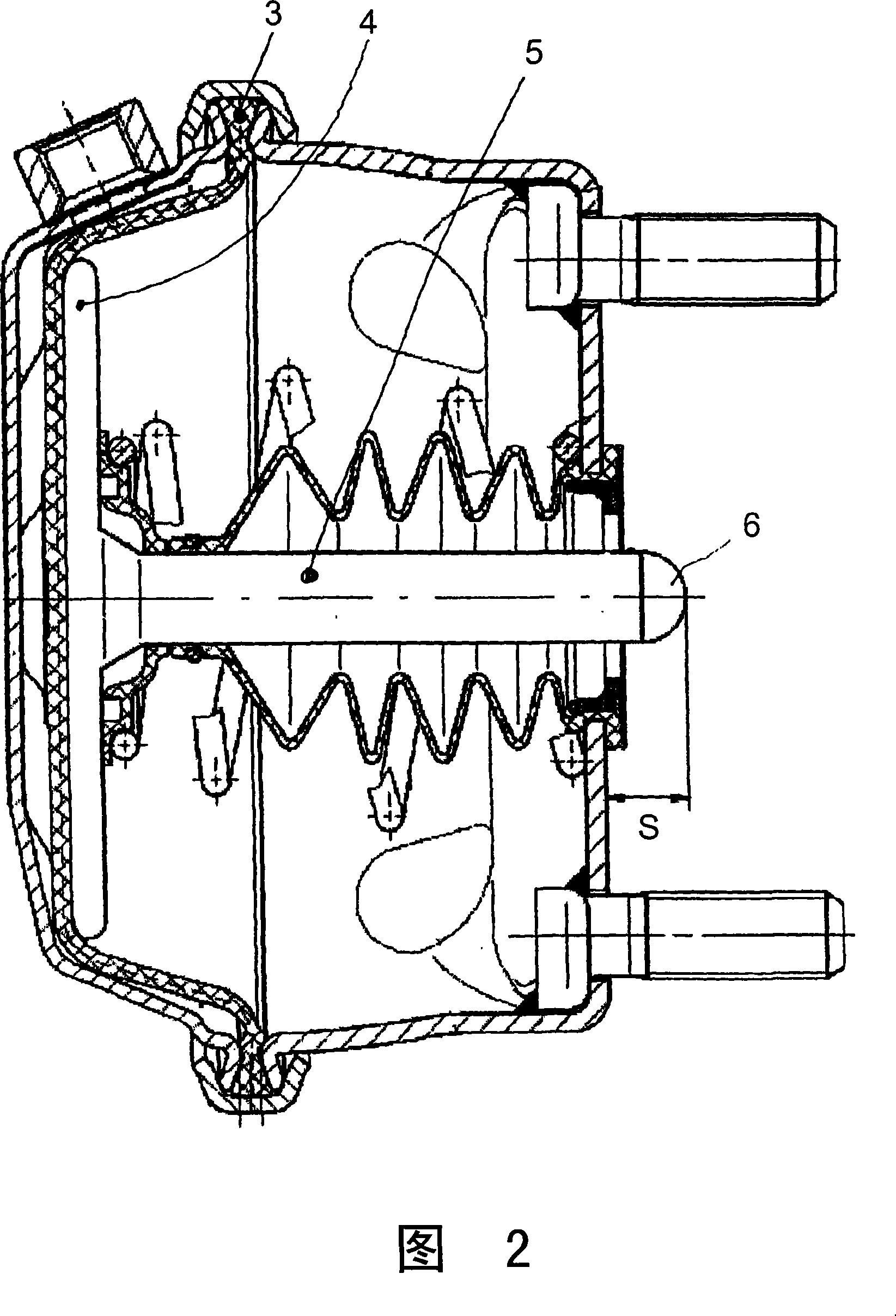

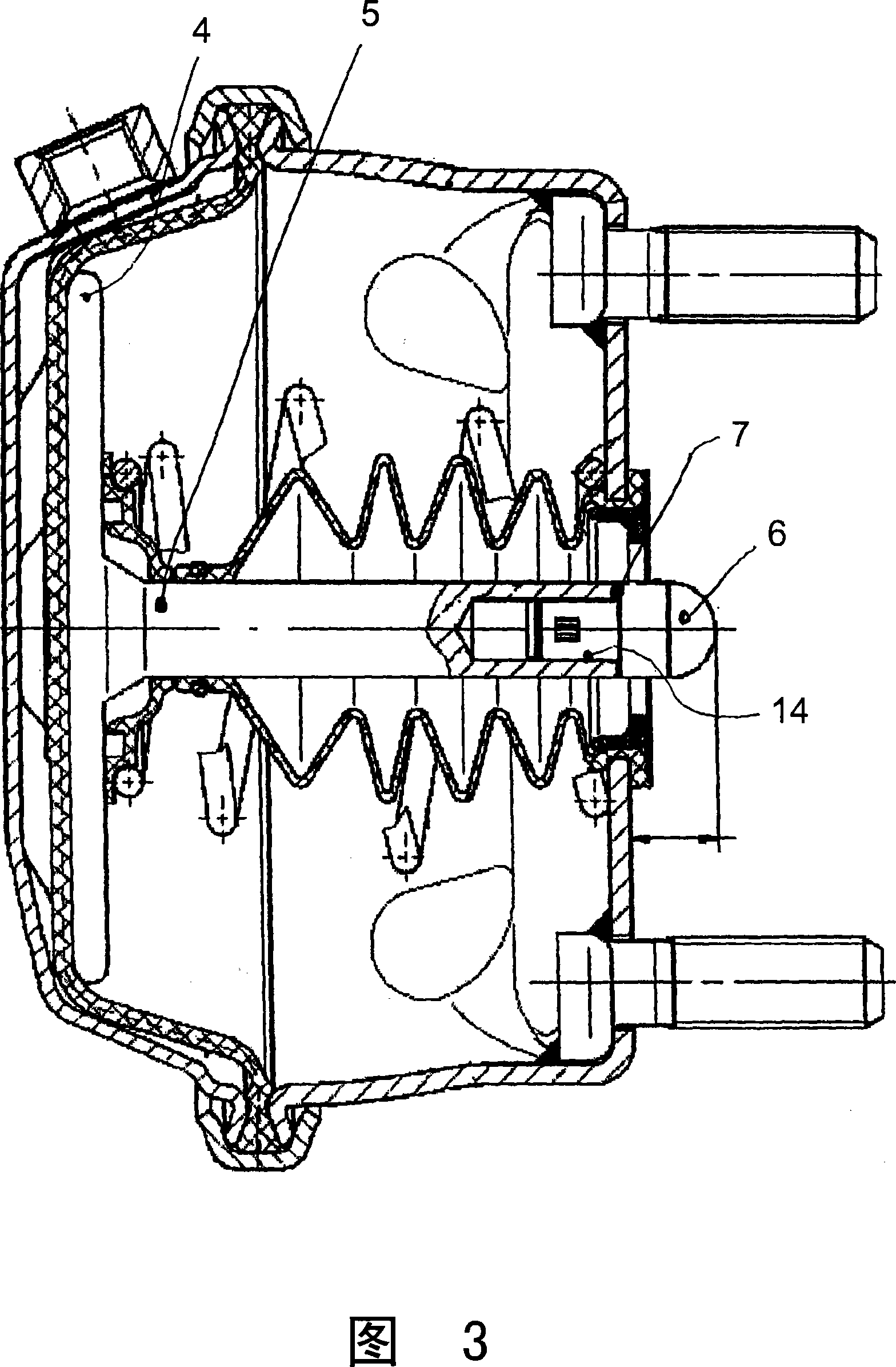

[0013] In FIG. 1, a compressed air brake cylinder of the prior art, in particular operating a disc brake of an automobile, is shown. It is formed by two shell covers 1, 10, which are joined together by curling edges 11. The housings 1 and 10 are fixed at suitable positions in the motor vehicle by means of fixing screws 11 and 12. The brake cylinder shown also includes a piston formed by a piston disk 4 and a piston rod 5. An independent pressure part 6 is installed on the right end of the piston rod 5, and the pressure part can be adjusted longitudinally by means of a compensation washer 7. Therefore, the length tolerance of the piston rod 5 can be compensated.

[0014] The brake cylinder also includes a rubber membrane 3 on which the piston disk 4 is supported.

[0015] Figure 1 shows the pistons 4, 5 in an entering state. The compressed air is supplied to the ventilation chamber 2 through the compressed air connection 12 to operate the piston. As a result, the pistons 4, 5 move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com