Numerical controller with machining resume function

A technology of numerical control device and function, applied in the direction of digital control, electrical program control, etc., can solve the problem of spending a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

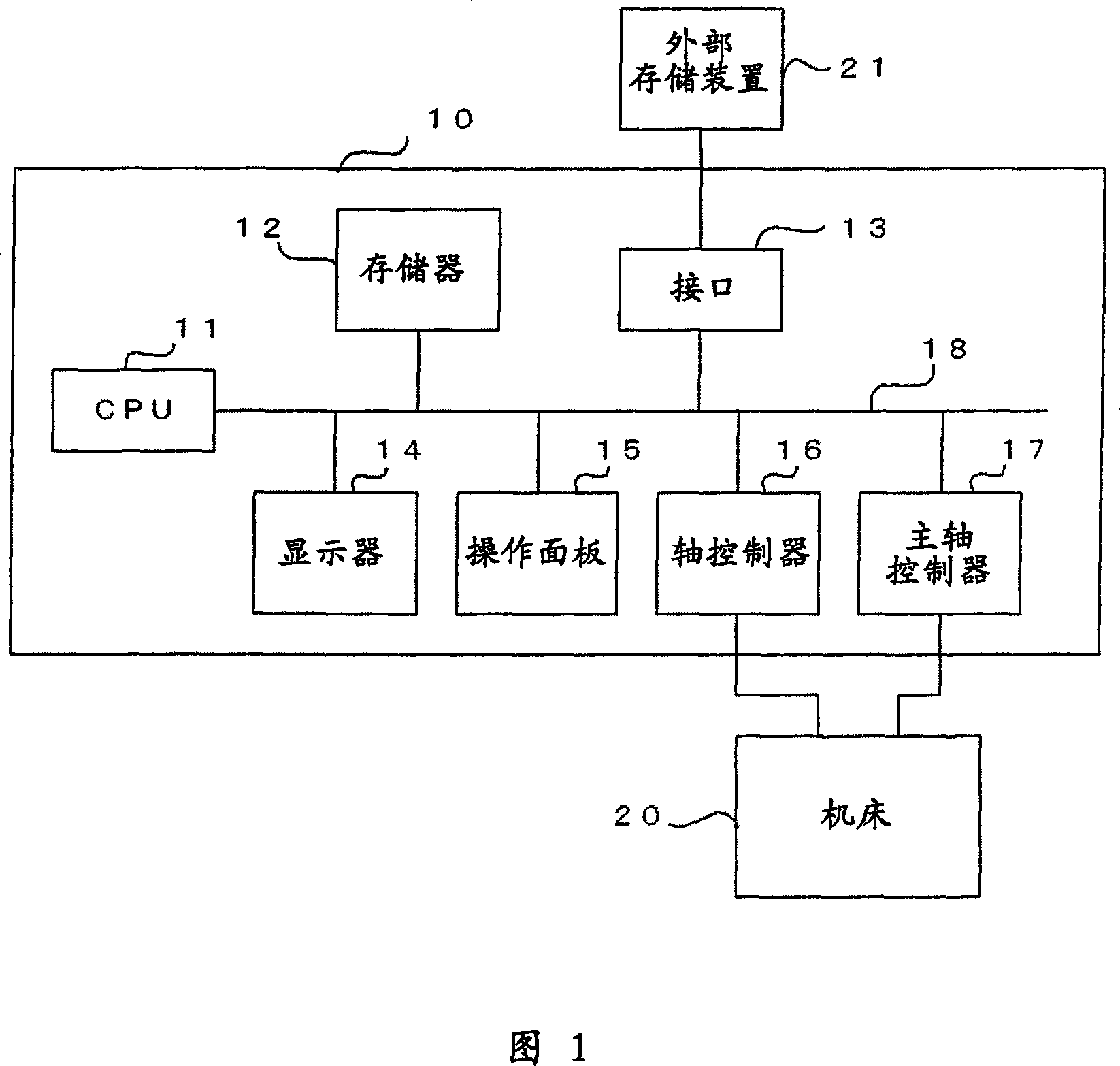

[0024] FIG. 1 is a schematic diagram of a numerical control device for controlling a machine tool according to an embodiment of the present invention. This numerical control device has the same hardware configuration as that of a conventional numerical control device for controlling a machine tool, and thus its hardware configuration is schematically shown in FIG. 1 . The difference between the numerical control device of the present invention and the conventional one is that the execution processing software part of the processing program stored in the memory (storage device) is different in order to realize the function of continuing processing, and the difference is also that the continuing processing described later is stored. functional software.

[0025] The numerical control device 10 has a memory (storage device) 12 connected to a processor (CPU) 11 through a bus 18; an interface 13; a display 14; an operation panel 15; an axis controller 16 for controlling a servomoto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com