Swinging movement hinge friction measurement device

A measuring device and friction force technology, which is applied in the field of swing hinge friction force measuring devices, can solve the problems of difficult measurement, complex sensors, and influence on measurement accuracy, and achieve the effects of simple structure, convenient measurement, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

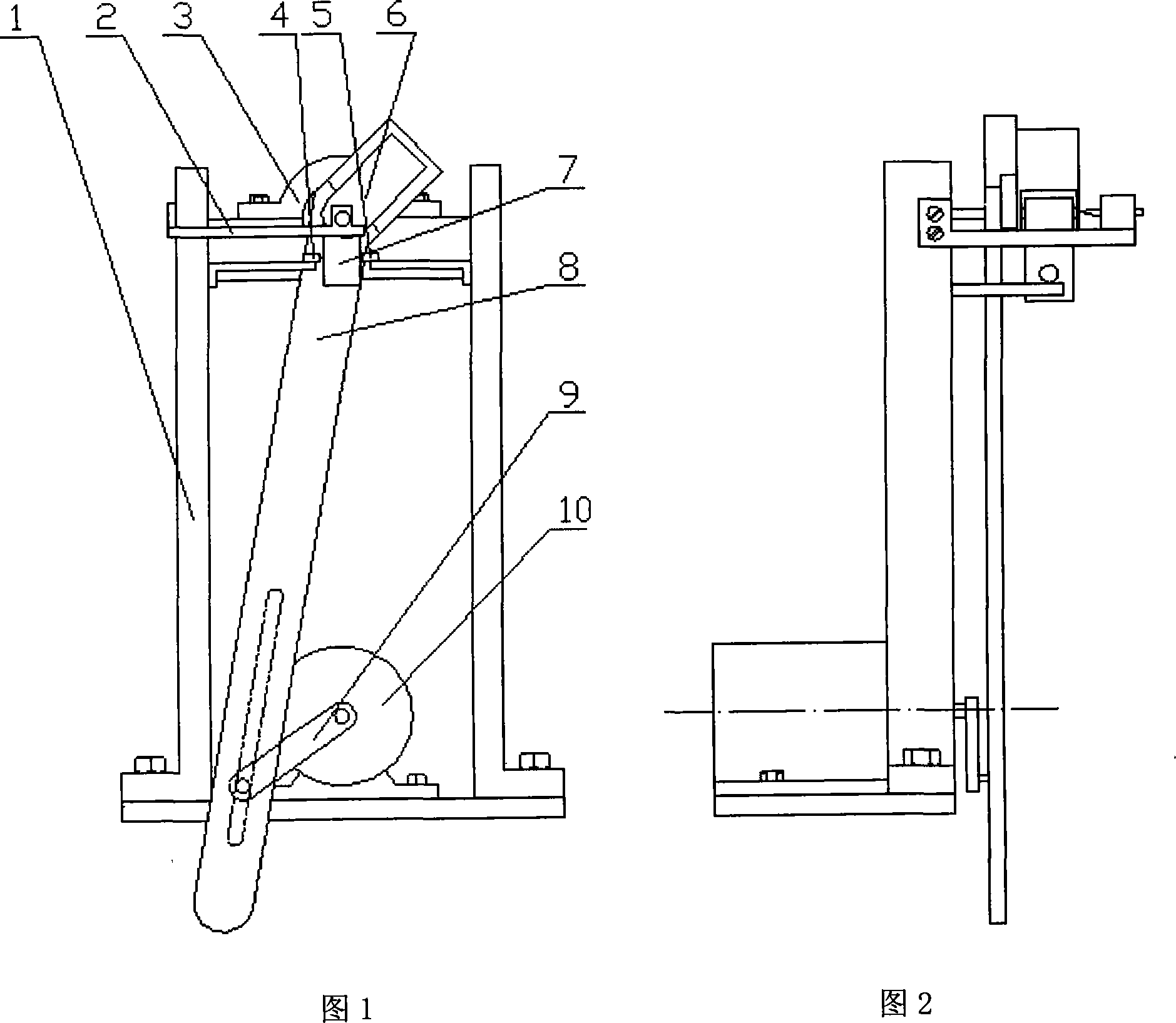

[0015] Combining Figures 1 and 2, the composition of the swing hinge friction measurement device includes a bracket 1, a coaxiality indicator arm 2, a bearing seat 3, pressure sensors 4 and 5, the swing side 6 of the hinge, the measurement side 7 of the hinge, the swing arm 8. Crank 9 and motor 10; wherein, the coaxiality indicator arm 2 is used to identify whether the rotation axis of the swing arm 8 coincides with the hinge; the bearing seat 3 supports the rotating shaft of the swing arm 8; the swing side of the swing arm 8 and the hinge 6 is fixed; when the hinge is installed, it is necessary to ensure that the rotation axis of the swing arm 8 coincides with the rotation axis of the hinge, but the two rotation axes are separated; the pressure sensors 4 and 5 are fixed on the bracket 1, and the measuring heads are respectively squeezed on the Both sides of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com