Overhead transverse hydro-cylinder forklift steering bridge

A forklift steering bridge and horizontal oil cylinder technology, which is applied to the steering mechanism, steering rod, vehicle parts, etc., can solve the problems of restricting the large swing angle of the steering mechanism and the reduction of steering resistance, so as to achieve a lower center of gravity, good steering performance, and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

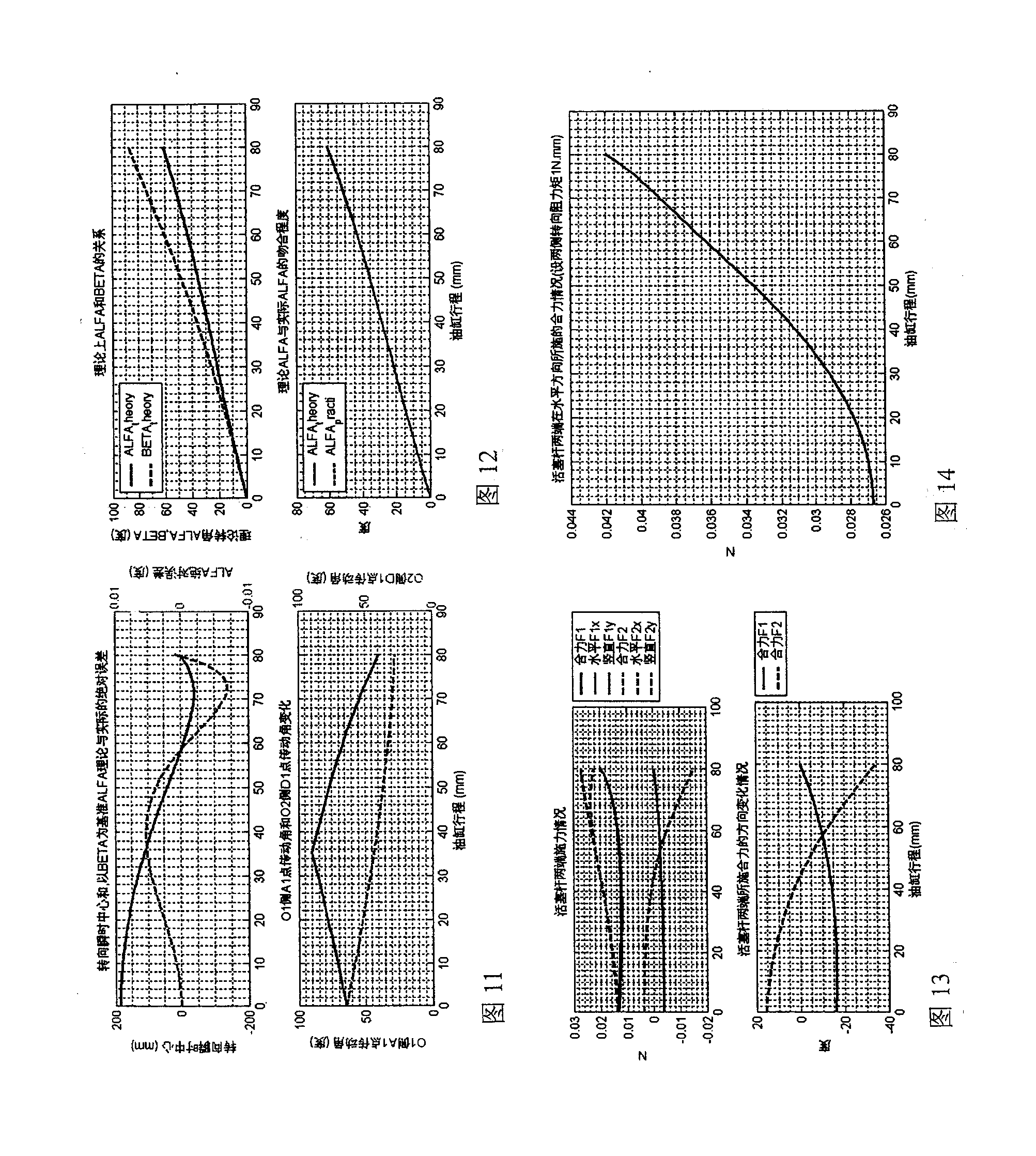

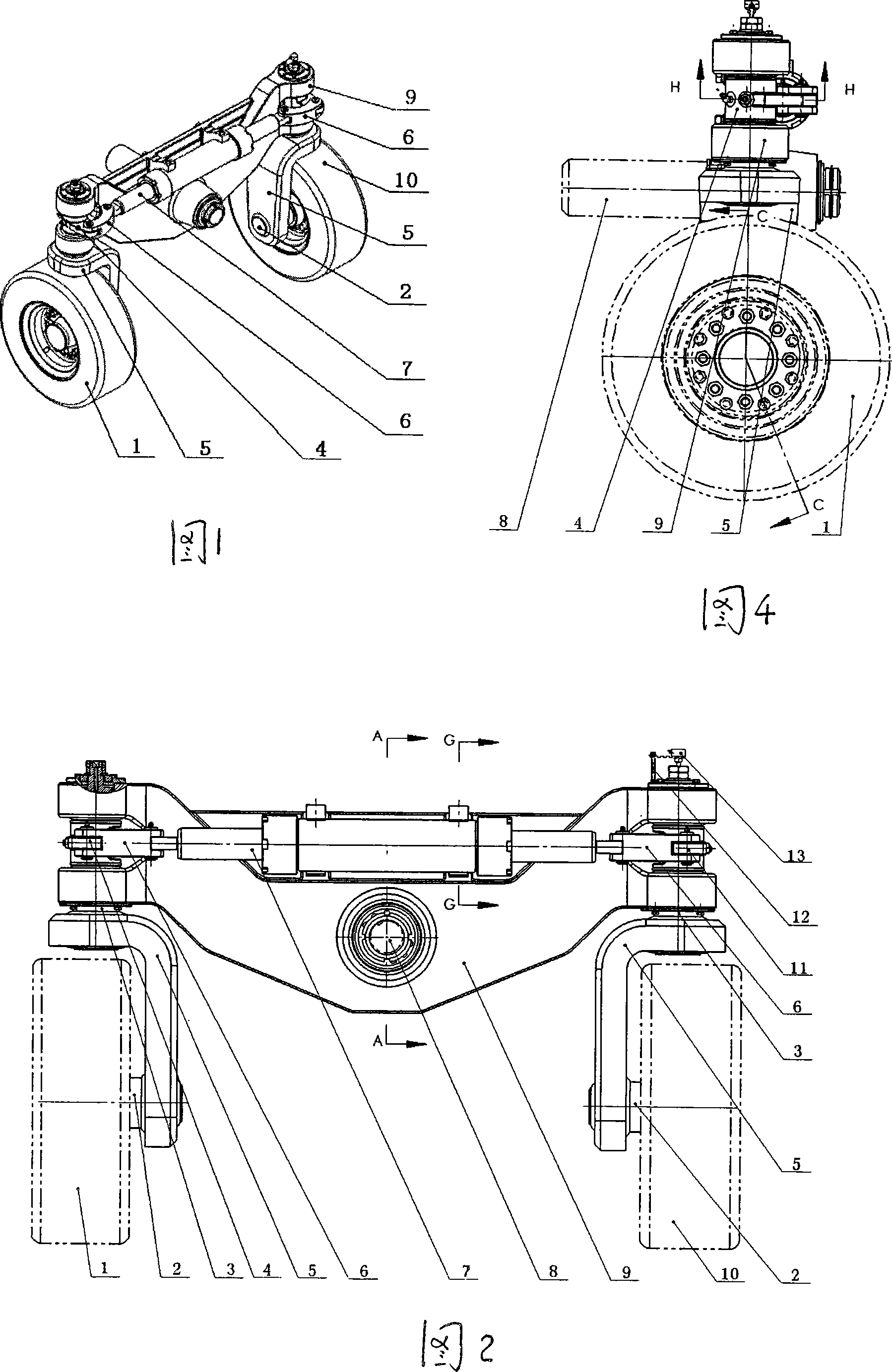

[0031] Referring to Figure 1, Figure 2, Figure 3 and Figure 4, the upper-mounted transverse cylinder forklift steering axle includes the bridge body 9, the transverse steering cylinder 7, the connecting rod 6, the left steering knuckle arm 4, the right steering knuckle arm 11, and the steering bend. Plate 5, the piston rods at both ends of the transverse steering cylinder 7 are respectively connected to the connecting rod 6, which is an arc-shaped rod; the other ends of the two connecting rods 6 are respectively connected to the left steering knuckle arm 4 and the right steering knuckle arm 11.

[0032] The bridge body 9 is V-shaped, and the middle of the V-shaped bridge body 9 is vertically connected to the mounting shaft 8 through the retaining ring 14, the thrust washer 15, the shaft sleeve 16, the bushing 17 and the retaining ring 18, as shown in Figure 5, the horizontal steering cylinder 7 is set above the mounting shaft 8, see Figures 2 and 8; the upper ends of the V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com