Variable valve control mechanism

A valve control and variable technology, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of the locking pin 14 not being able to enter the accommodating space smoothly, the influence of valve actuation, and the failure of lift switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a further cognition and understanding of the features, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be described below, and the detailed description is as follows:

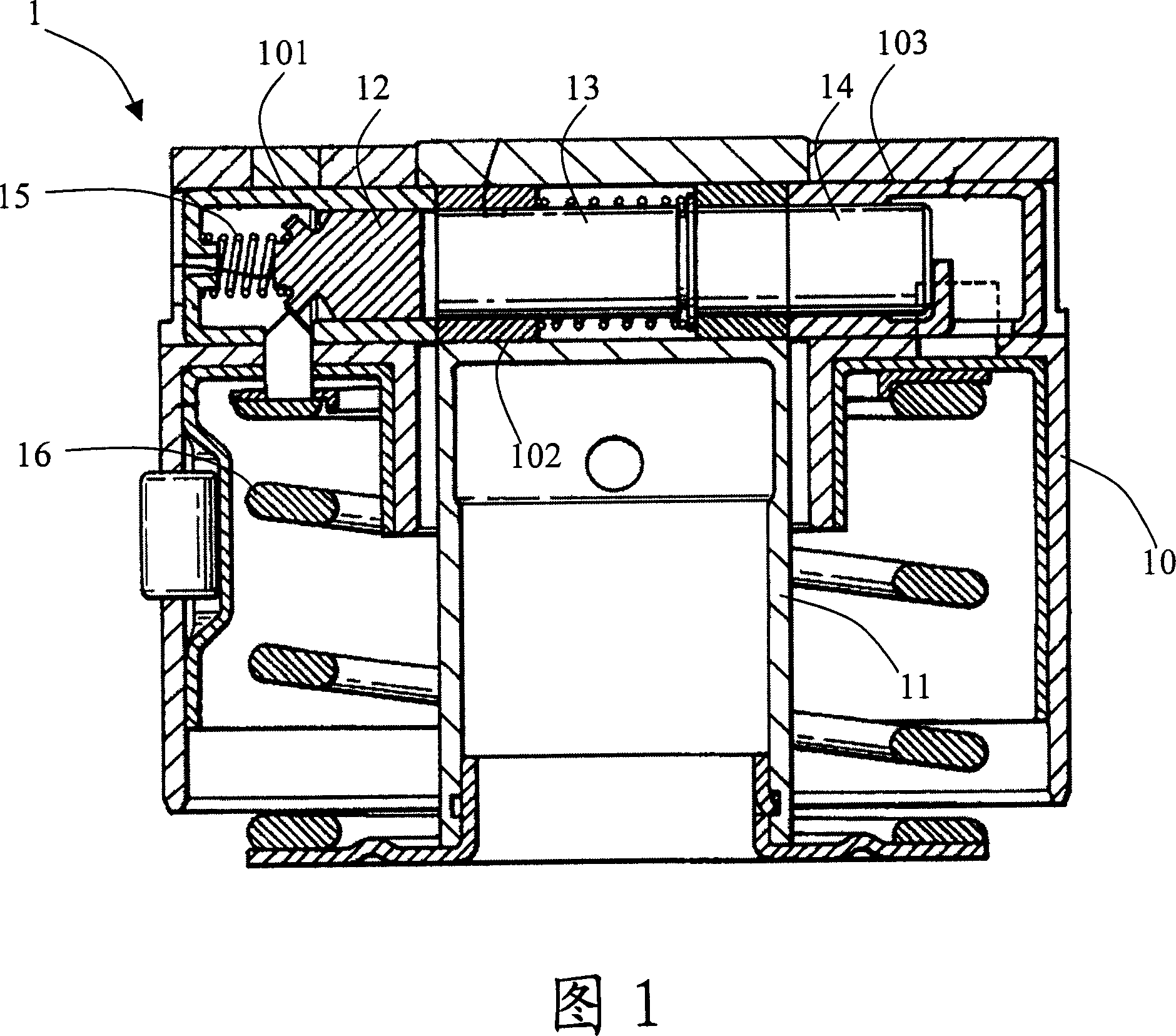

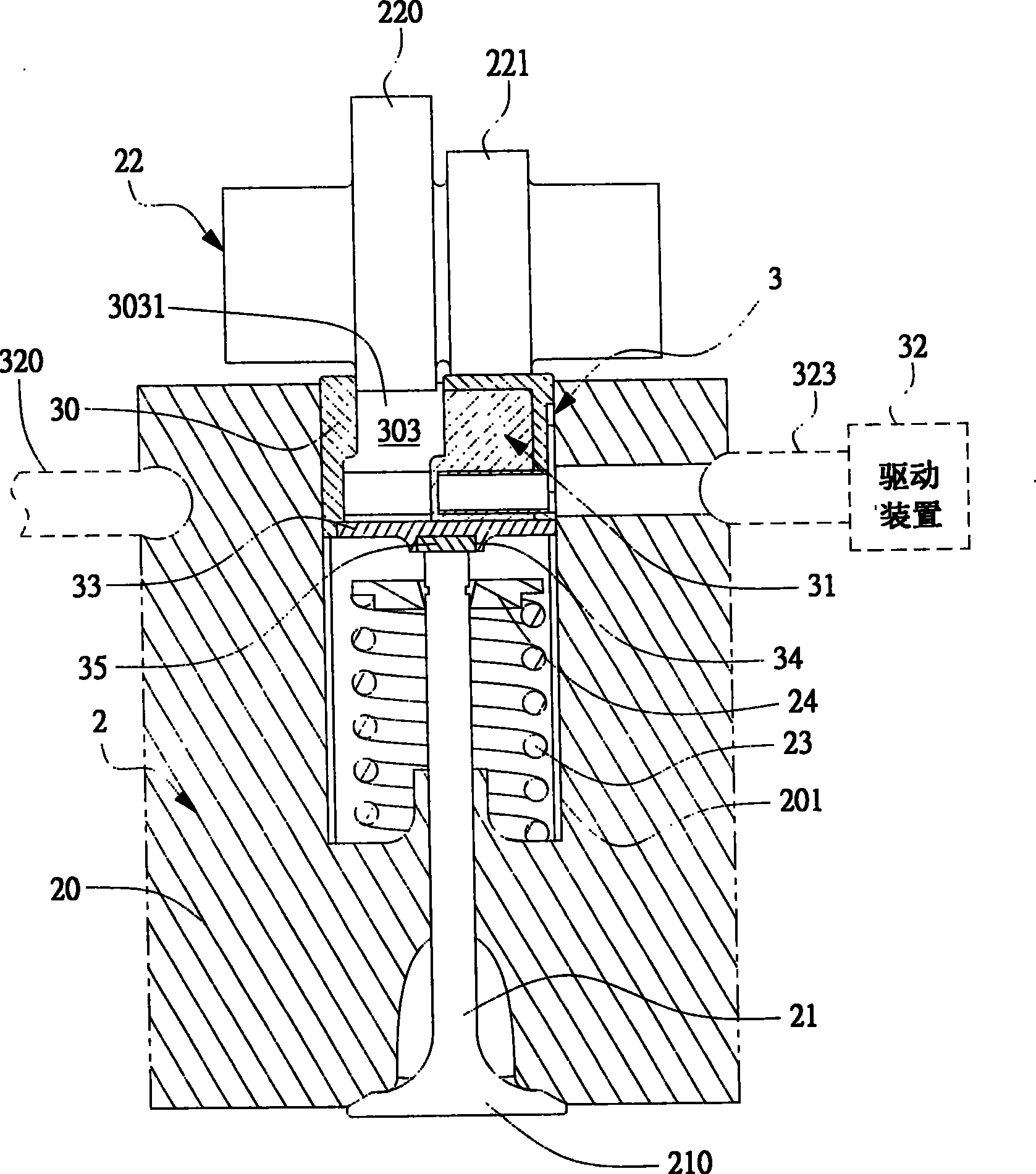

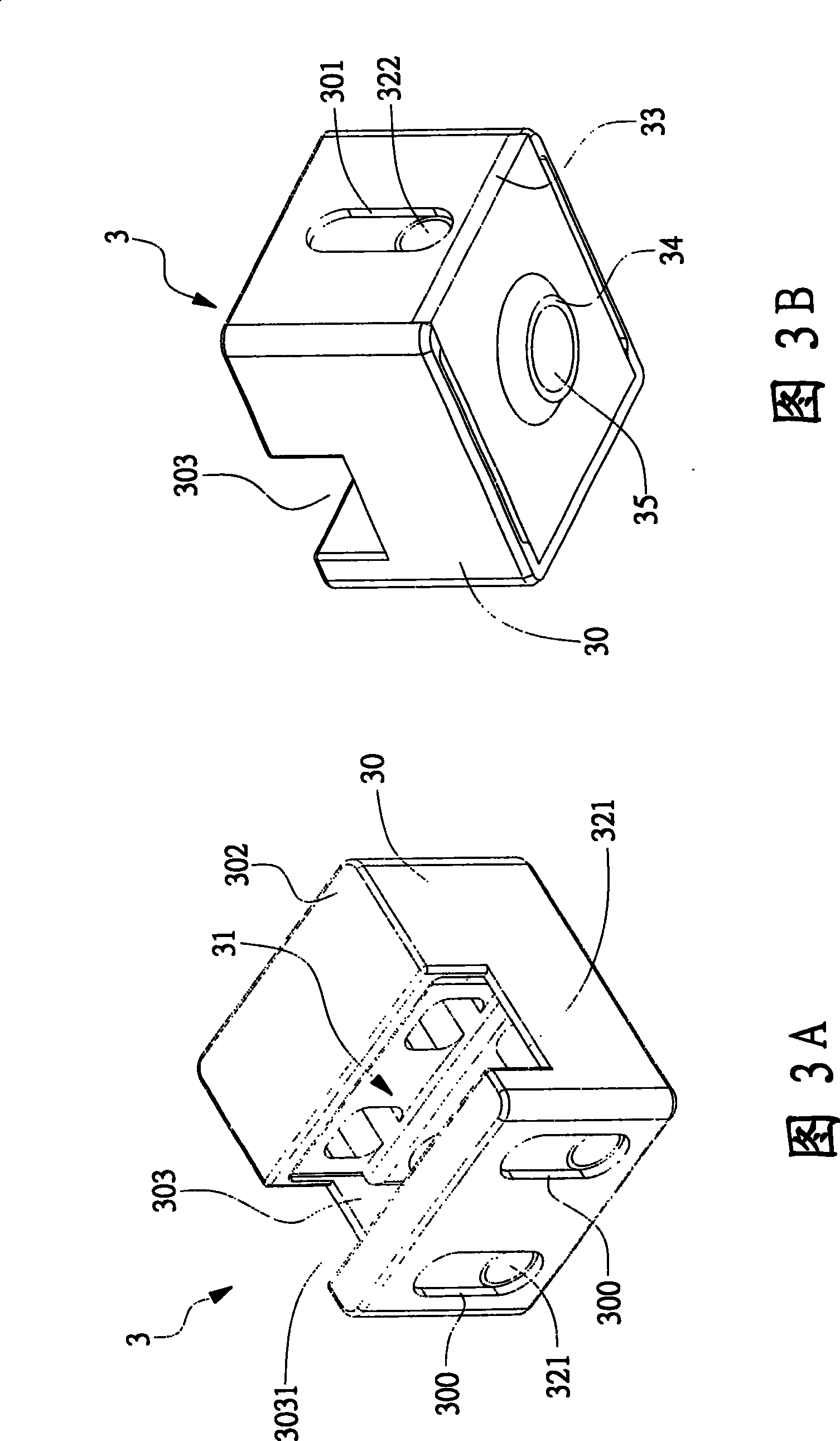

[0036] see figure 2 As shown, the figure is a schematic diagram of the combined state of the first preferred embodiment of the variable valve control mechanism of the present invention and the engine. The variable valve control mechanism 3 can control the lift of the valve through the driving force provided by an actuating mechanism 22. The variable valve control mechanism 3 includes an outer push cylinder 30, a slide block 31 and A driving device 32 . The outer jack 30 is disposed in the cylinder head 20 of the engine 2 and abuts against a valve rod 21 . A receiving space 303 is defined in the outer jack 30 , and the receiving space has an opening 3031 . The slider 31 is disposed in the acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com