Organic light emitting display and voltage compensation technology organic light emitting pixel

A light-emitting display, organic technology, applied in the direction of electroluminescent light source, static indicator, instrument, etc., can solve the problem that the display brightness cannot reach the display brightness, the node X does not reach the stable offset, and the time is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

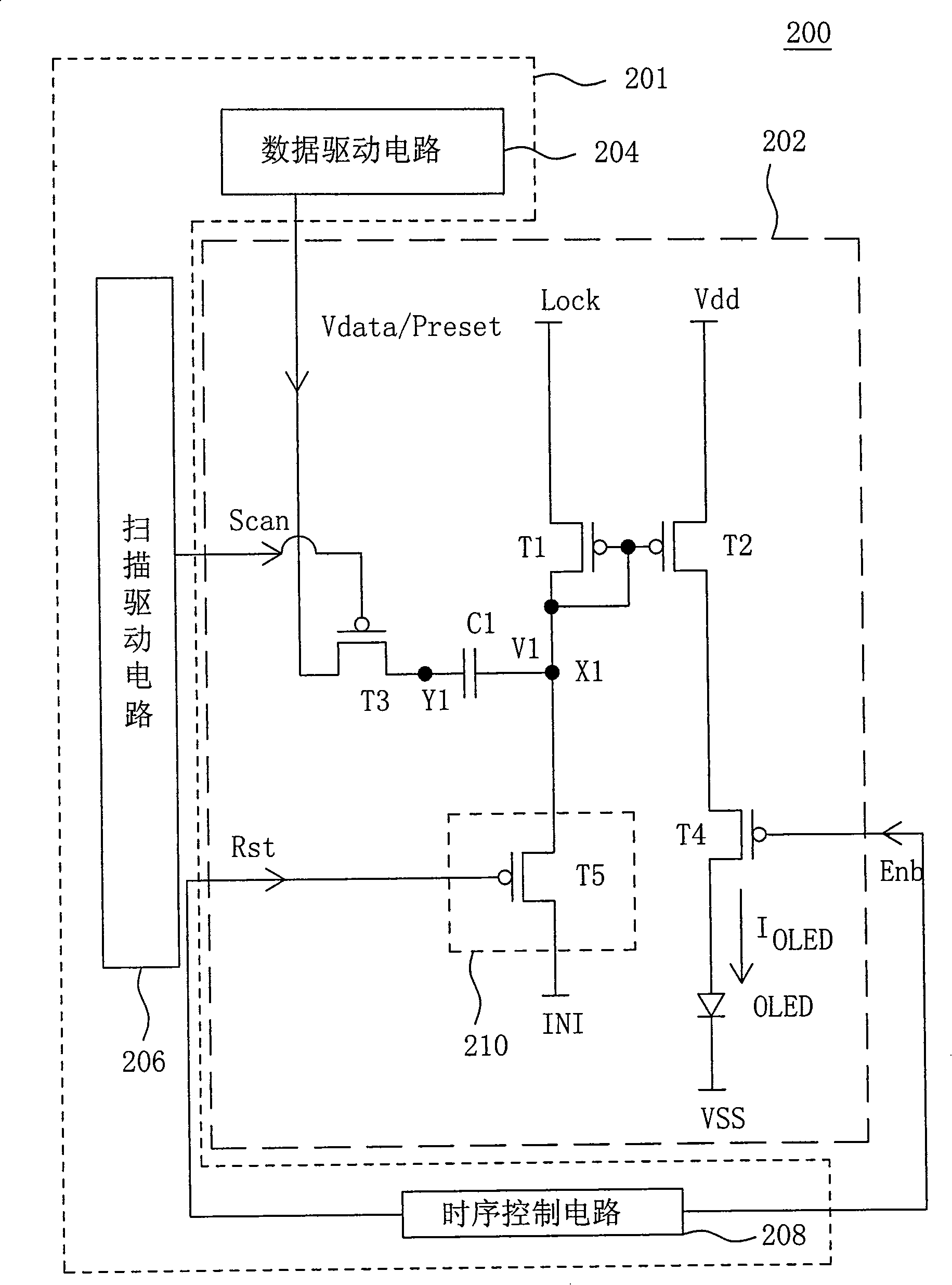

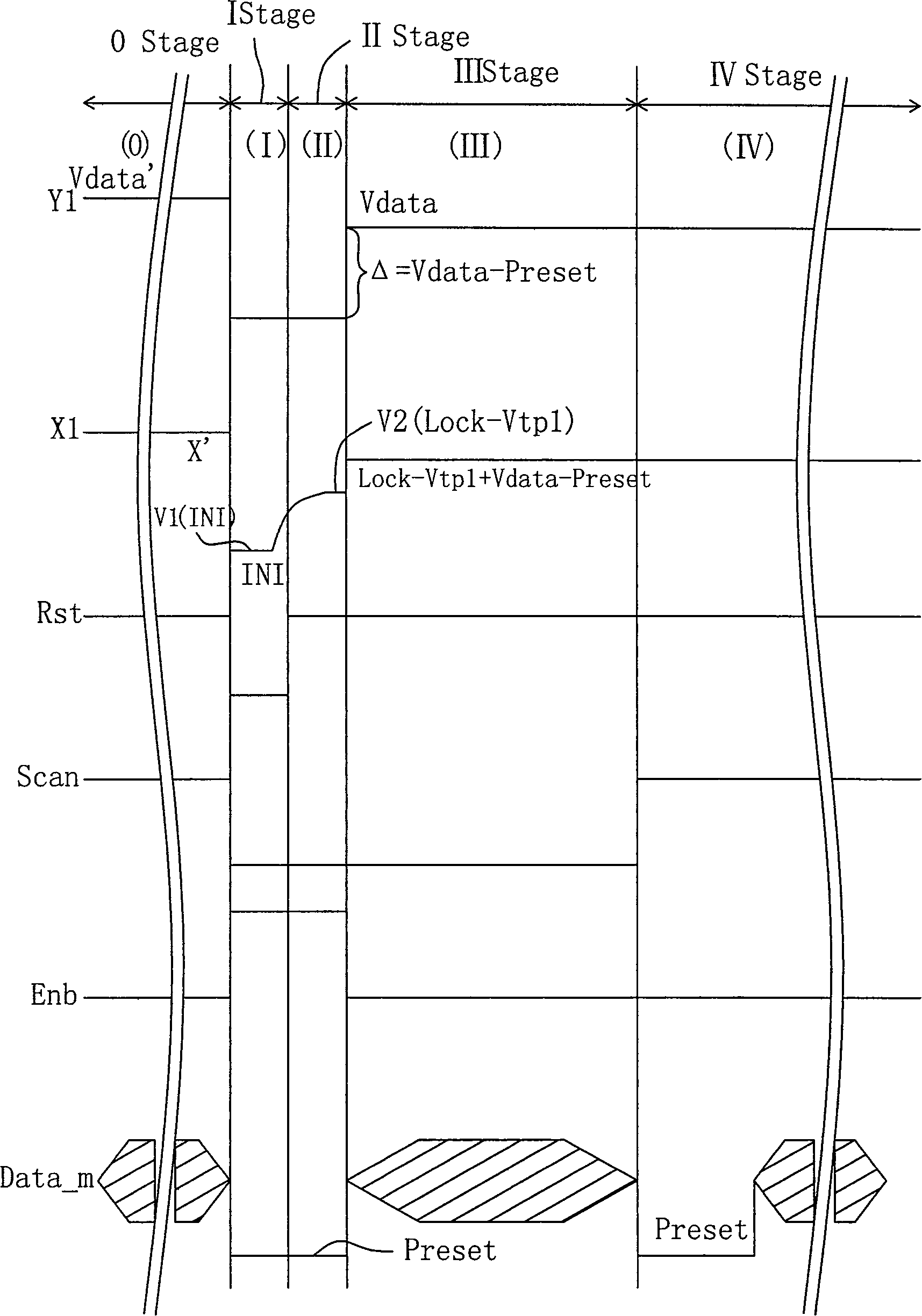

[0043] Please refer to figure 2 , which is a schematic diagram of an organic light emitting display according to a first embodiment of the present invention. The organic light emitting display 200 includes a driving unit 201 and organic light emitting pixels 202 . The driving unit 201 is used to drive the pixels 202 , and includes a data driving circuit 204 , a scanning driving circuit 206 and a timing control circuit 208 . The data driving circuit 204 outputs a fifth voltage to the organic light emitting pixel 202 according to the image data, wherein the fifth voltage is the pixel voltage Vdata or the low level voltage Preset. The scan driving circuit 206 is used for outputting a scan signal Scan. The timing control circuit 208 is used to output the first control signal Enb to the fifth thin film transistor T5 , and is also used to output the second control signal Rst to the reset circuit 210 . The driving unit 201 also provides a first voltage Lock, a second voltage Vdd,...

no. 2 example

[0058] This implementation differs from the first embodiment in the structure of the reset circuit. The reset circuit is instead composed of two thin film transistors which are respectively electrically connected to the two ends of the first capacitor for resetting the first capacitor and setting the potential on the node X1.

[0059] Please refer to Figure 10 , which is a schematic diagram of an organic light emitting display according to a second embodiment of the present invention. The organic light emitting display 1000 also includes a driving unit 1001 and an organic light emitting pixel 1002 . The driving unit 1001 includes a data driving circuit 1004 , a scanning driving circuit 1006 and a timing controller 1008 . The organic light emitting pixel 1002 also includes a first capacitor C1 , a first thin film transistor T1 , a second thin film transistor T2 , a third thin film transistor T3 , a fourth thin film transistor T4 , a reset circuit 1010 and an organic light em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com