Cigarettes and filter subassemblies with squeezable flavor capsule and methods of manufacture

A filter tip and cigarette technology, applied in the manufacture of paper cigarettes, e-liquid filters, tobacco, etc., can solve problems such as loss of volatile flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

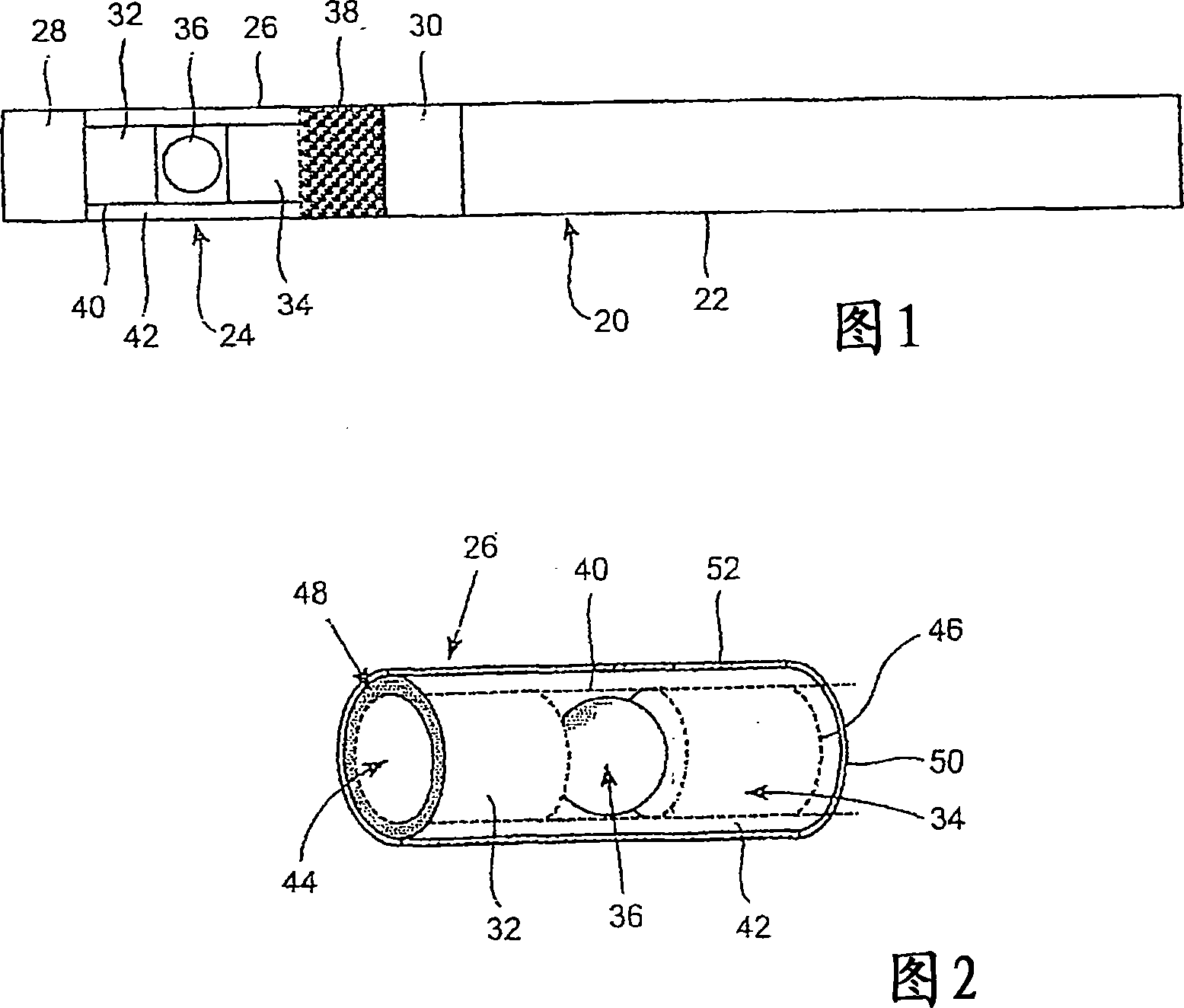

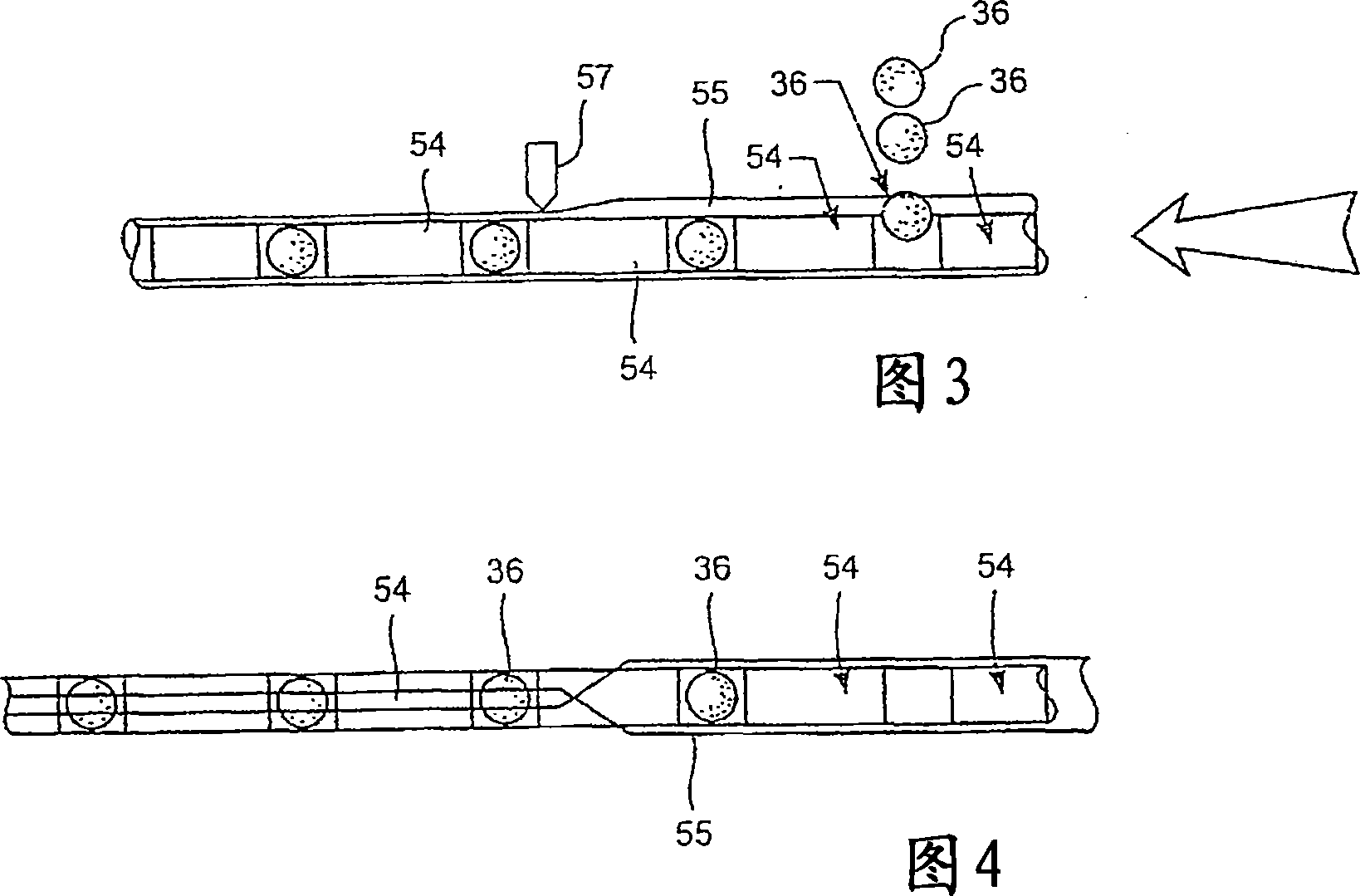

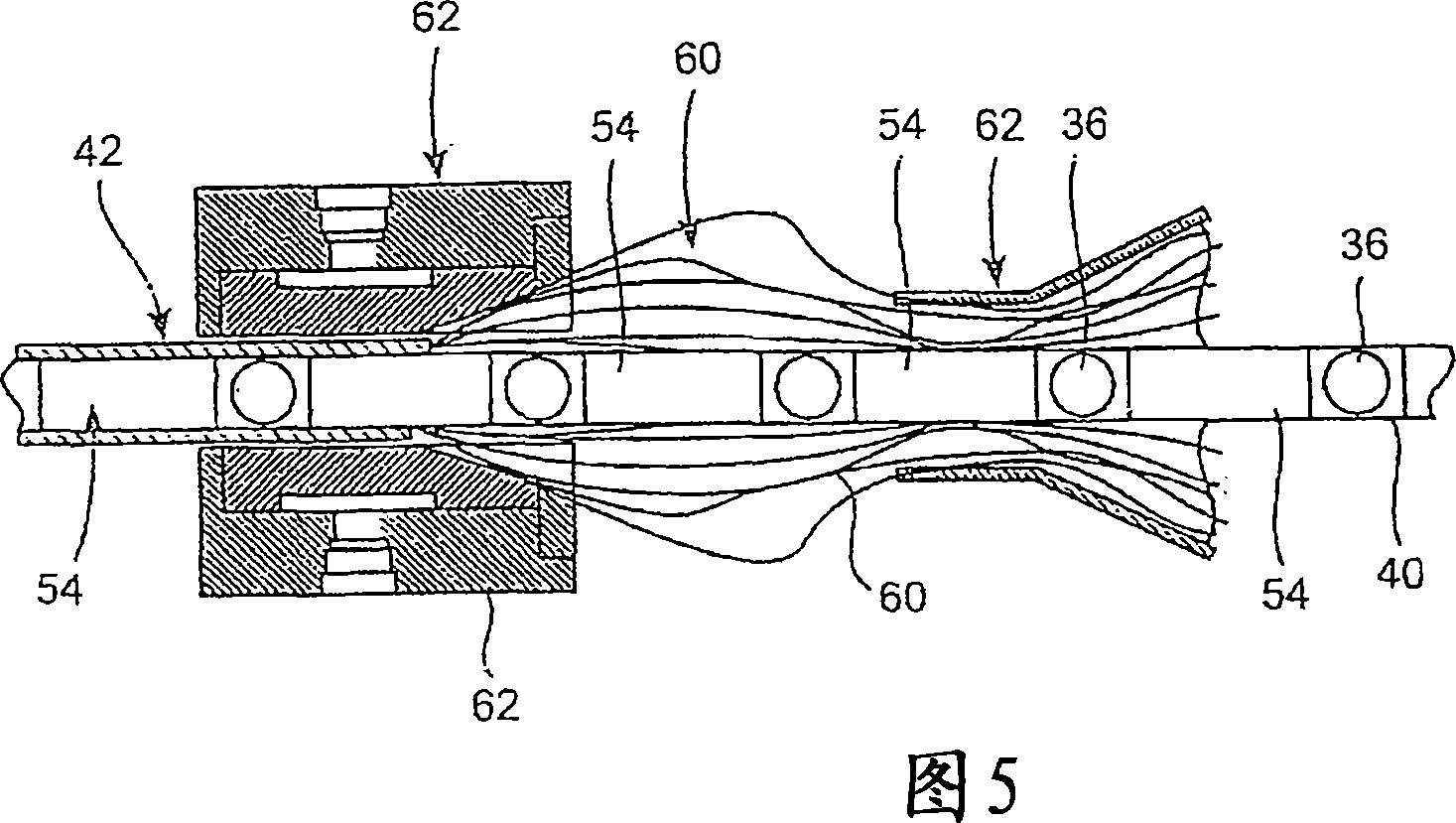

[0022] A filter device is provided with an additive material, such as a flavoring ingredient, in a tobacco product, such as a cigarette. By using one or more capsules, preferably sealed or frangible capsules, comprising the additive material, an improved delivery capability by controlled release of the additive material to the cigarette can be obtained. The use of capsules allows the core of the capsules to be released in a controlled manner by the smoker. This controlled release provided by the capsule can reduce the reaction between the additive material and the cigarette, can reduce the evaporation and migration of the additive material within the cigarette, can allow uniform or non-uniform distribution of the additive material, and / or can control the amount of the additive material. Release to achieve proper timing until a predetermined stimulus occurs, and / or may allow in situ mixing of additive materials.

[0023] The one or more capsules are preferably contained in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap